Copper-cladded iron alloy composite conductor and its preparing method

A composite wire, ferroalloy technology, used in cable/conductor manufacturing, conductors, non-insulated conductors, etc., can solve the problems of hard material, high cost and high processing cost, achieve high tensile strength and elongation, and have a wide range of applications. The effect of material cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

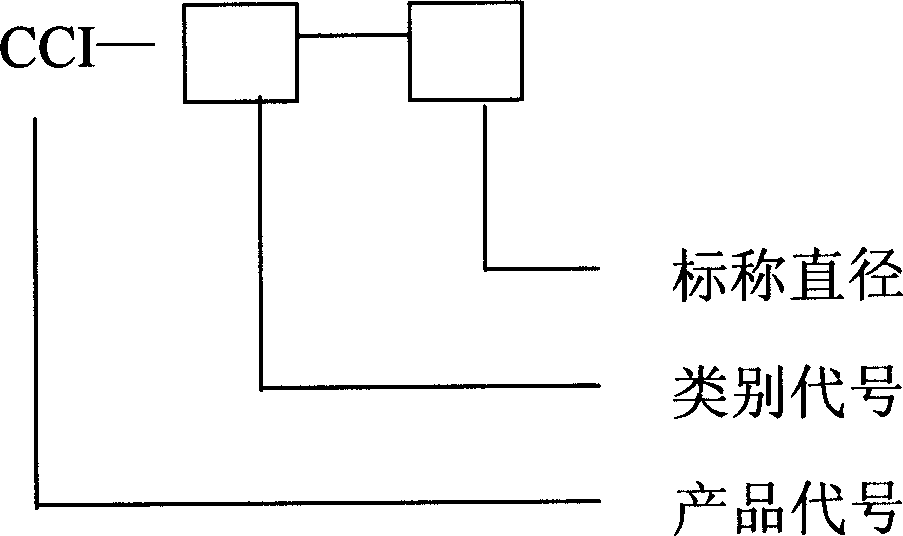

Image

Examples

Embodiment 1

[0028] Example 1: A. Use a wire wheel to mechanically or chemically treat a fully soft copper strip (99.9% by weight) and a ferroalloy wire with a diameter of 10mm and a composition of 20% copper weight and 80% iron weight. Removal of grease and oxidized passivation layer on the surface;

[0029] B. Wrap the copper strip on the iron alloy wire with a diameter of 10mm to make a composite blank;

[0030] C. The composite blank is drawn with a speed of 100m / min and a diameter reduction rate of 18%, and the wire diameter is 3.0mm;

[0031] D. Adjust the drawing speed to 130 / min, and the diameter reduction rate is 15% for drawing, and the wire diameter is 2.15mm.

[0032] E. Adjust the drawing speed to 800 / min, and the diameter reduction rate is 15% for drawing. The composite blank is processed to a copper-clad iron alloy wire with a wire diameter of 1.5mm.

Embodiment 2

[0033] Example 2: A. Use a wire wheel to mechanically or chemically treat a fully soft copper strip (99.95% by weight) and a ferroalloy wire with a diameter of 8mm, 40% copper weight and 60% iron weight to remove the grease on the surface And oxidation passivation layer removal;

[0034] B. Cladding copper on a ferroalloy wire with a diameter of 8mm to make a composite blank;

[0035] C. The composite blank is drawn to a wire diameter of 1.0mm with a speed of 150m / min and a diameter reduction rate of 13%;

[0036] D. Adjust the drawing speed to 800m / min and the reduction rate of 12% to draw to a wire diameter of 0.55mm;

[0037] E. Adjust the drawing speed to 1500m / min and the reduction rate of 10% to draw to a wire diameter of 0.25mm.

[0038] F. Adjust the drawing speed to 2000m / min and the reduction rate of 8% to draw to a wire diameter of 0.08mm.

[0039] In the process of drawing from 0.08mm-1.0mm, annealing treatment is required, and the temperature should be controlled betw...

Embodiment 3

[0040] Example 3: A. Use a wire wheel to mechanically or chemically treat a fully soft copper strip (99.98% by weight) and a ferroalloy wire with a diameter of 6mm, 30% copper weight and 70% iron weight to remove the grease on the surface And oxidation passivation layer removal;

[0041] B. Cladding copper on a ferroalloy wire with a diameter of 6mm to make a composite blank;

[0042] C. The composite blank is drawn to a wire diameter of 1.5mm with a speed of 150m / min and a diameter reduction rate of 15%;

[0043] D. Adjust the drawing speed to 1200m / min and the reduction rate of 8% to draw to a wire diameter of 0.25mm;

[0044] E. Adjust the drawing speed to 2500m / min and the reduction rate of 3% to draw to a wire diameter of 0.08mm.

[0045] In the process of drawing from 0.08mm-1.0mm, annealing treatment is required, and the temperature should be controlled between 500℃-700℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com