Method of producing unsaturated aldehyde and unsaturated acid in fixed-bed catalytic partial oxidation reactor with enhanced heat control system

一种床催化部分、不饱和的技术,应用在化学仪器和方法、有机化合物的制备、氧化制备羰基化合物等方向,能够解决催化剂寿命周期减小、选择性下降、催化剂性能下降等问题,达到抑制热累积、防止产率下降、抑制副反应的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] Example 1 (Improved Thermal Control System): Changes in Yield and Size of Temperature Peaks at Hot Spots with Changes in Set Temperature of Molten Salt

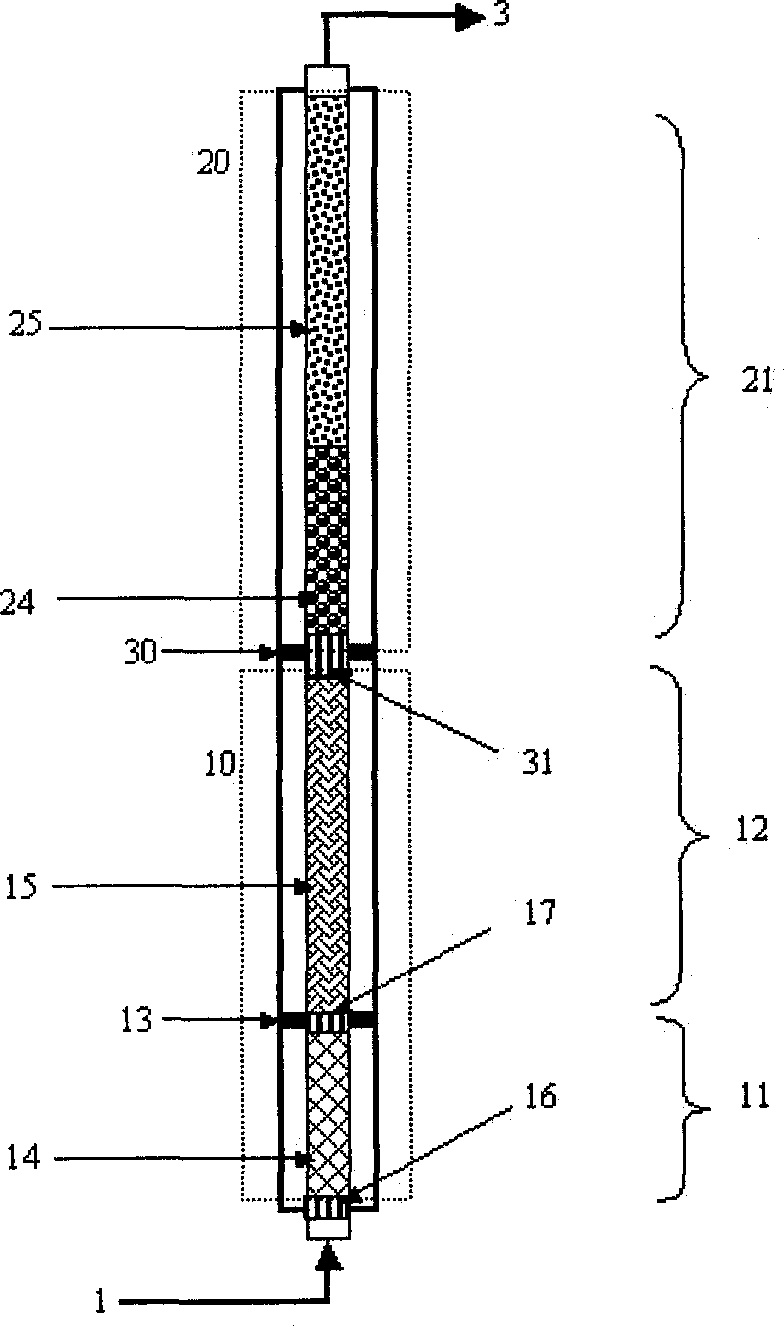

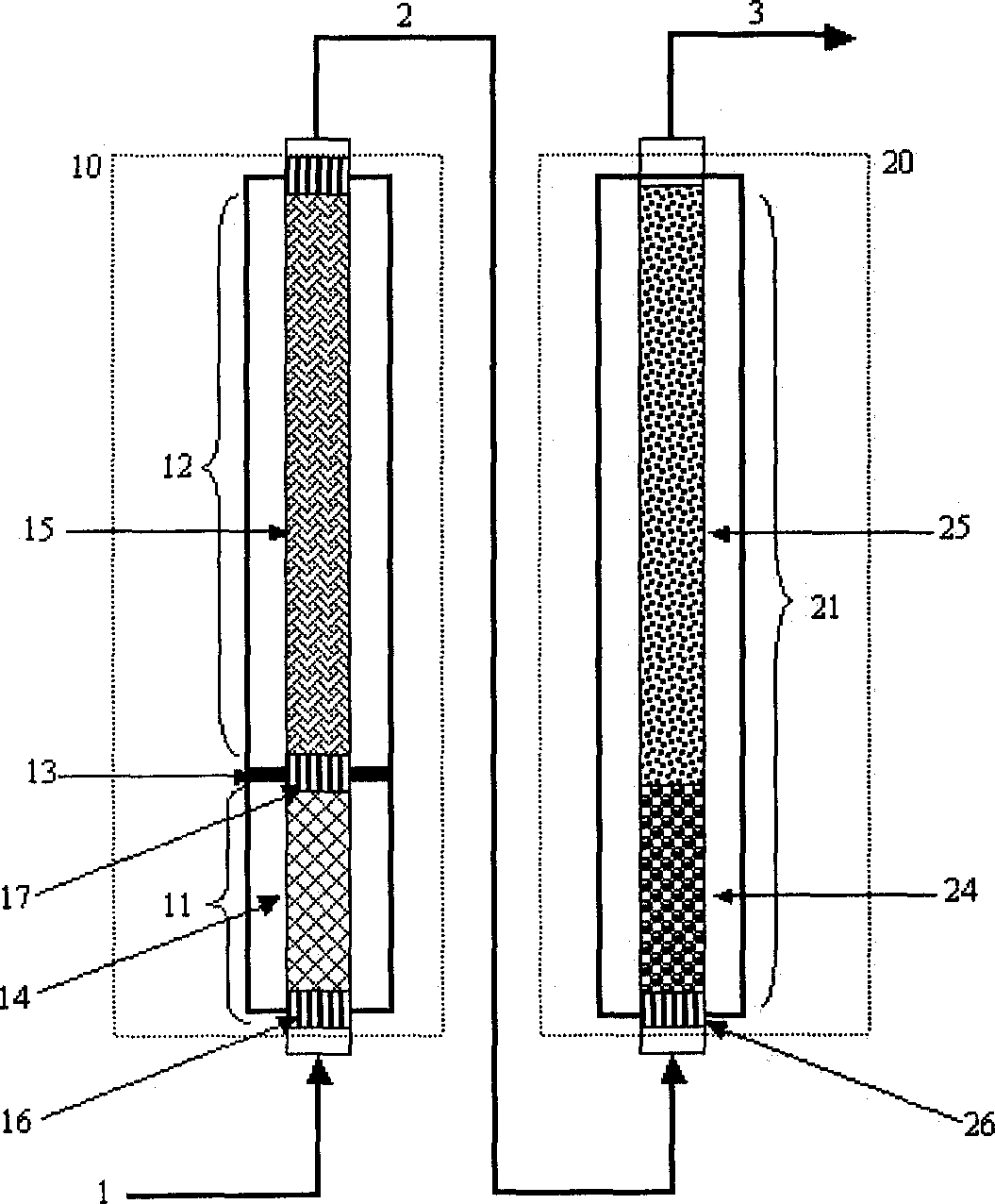

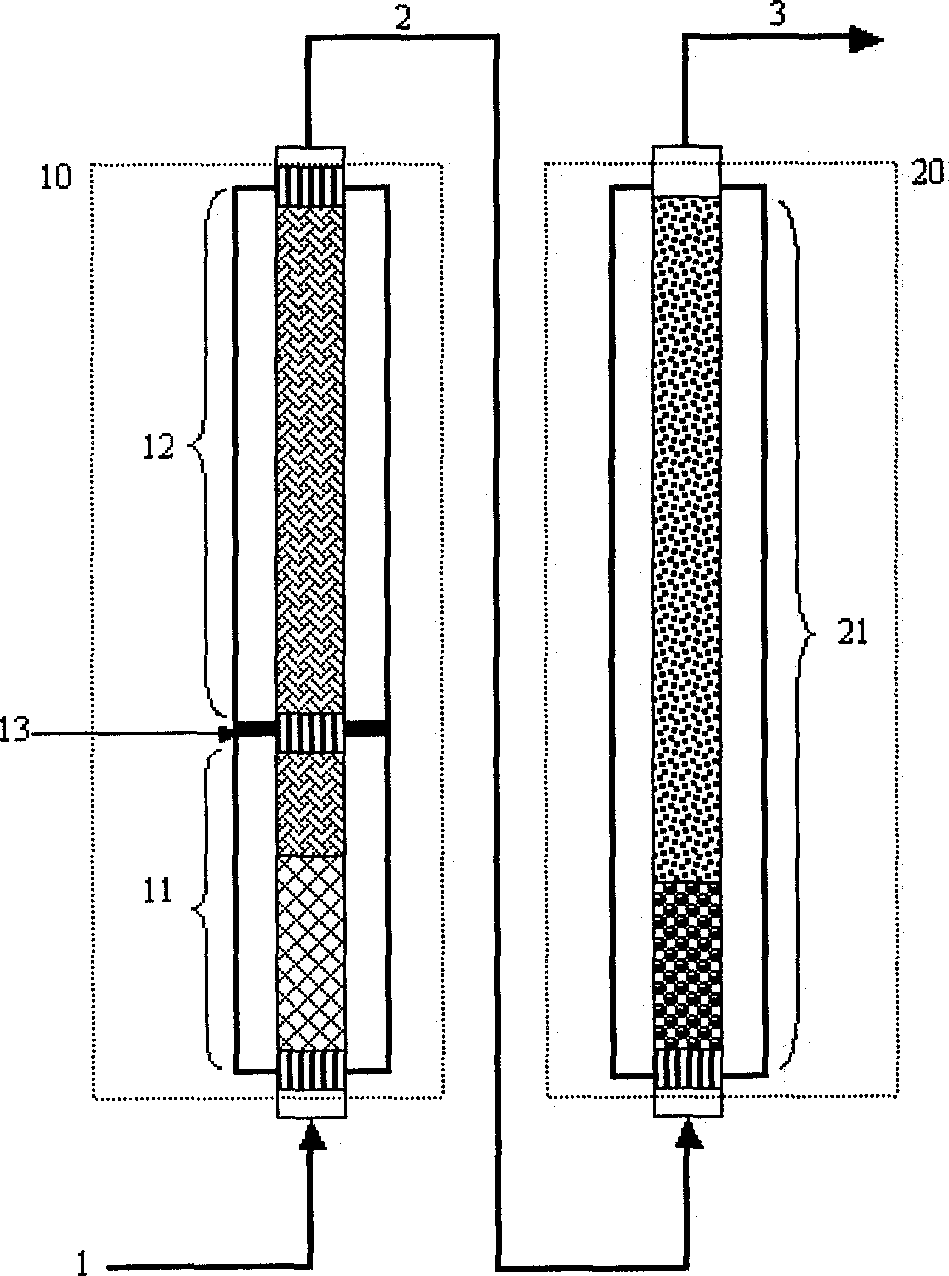

[0092] Such as image 3 As shown, each first-step reaction and second-step reaction are provided in a catalytic tube (included in image 3 Pilot reactors performed in zones 10 or 20). The inner diameter of each catalytic tube was 26 mm, and the first step catalytic tube was filled with a catalytic layer with a height of about 1200 mm, and the second step catalytic tube was filled with a catalytic layer with a height of about 1100 mm. image 3 The reference numerals 11 and 12 in refer to the partitioned shell spaces of the first step reaction zone. The temperatures of the molten salts filled in the shell spaces were 300°C and 305°C, respectively. image 3 Reference numeral 21 in refers to the shell space filled with molten salt and set to 265°C. The two catalyst layers filled in the first step reaction zone 10 are m...

Embodiment 2

[0097] Example 2 (Improved Thermal Control System): With the change of the set temperature of the molten salt, the change of the yield and the size of the temperature peak at the hot spot

[0098]This example was carried out in the same manner as in Example 1 except for the set temperature of the molten salt in the first-step reaction zone (first-step reactor). The temperatures of the molten salt in the reaction zone of the first step are respectively set to 300°C and 310°C along the axial direction.

[0099] In the region corresponding to the first shell space in the reaction region of the first step, a hot spot having a temperature of 381.5° C. was formed. The yields of acrolein and acrylic acid were 81.13% and 9.30%, respectively. In the second-step reaction zone operated under isothermal conditions, the temperature of the hot spot was 320.0° C., and the yields of acrolein and acrylic acid were 1.18% and 84.35%, respectively.

Embodiment 3

[0100] Example 3 (Improved Thermal Control System): Changes in Yield and Size of Temperature Peaks at Hot Spots with Changes in Set Temperature of Molten Salt

[0101] This example was carried out in the same manner as in Example 1 except for the set temperature of the molten salt in the first-step reaction zone (first-step reactor). The temperatures of the molten salt in the reaction zone of the first step are respectively set to 300°C and 315°C along the axial direction.

[0102] In the region corresponding to the first shell space in the reaction region of the first step, a hot spot having a temperature of 381.2° C. was formed. The yields of acrolein and acrylic acid were 79.02% and 11.46%, respectively. In the second-stage reaction zone operated under isothermal conditions, the temperature of the hot spot was 327.5° C., and the yields of acrolein and acrylic acid were 0.607% and 84.95%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com