Treating method of lacquer spraying waste gas

A waste gas, dry process technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of long process, clogging, limited absorption effect, etc., to achieve the effect of zero emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

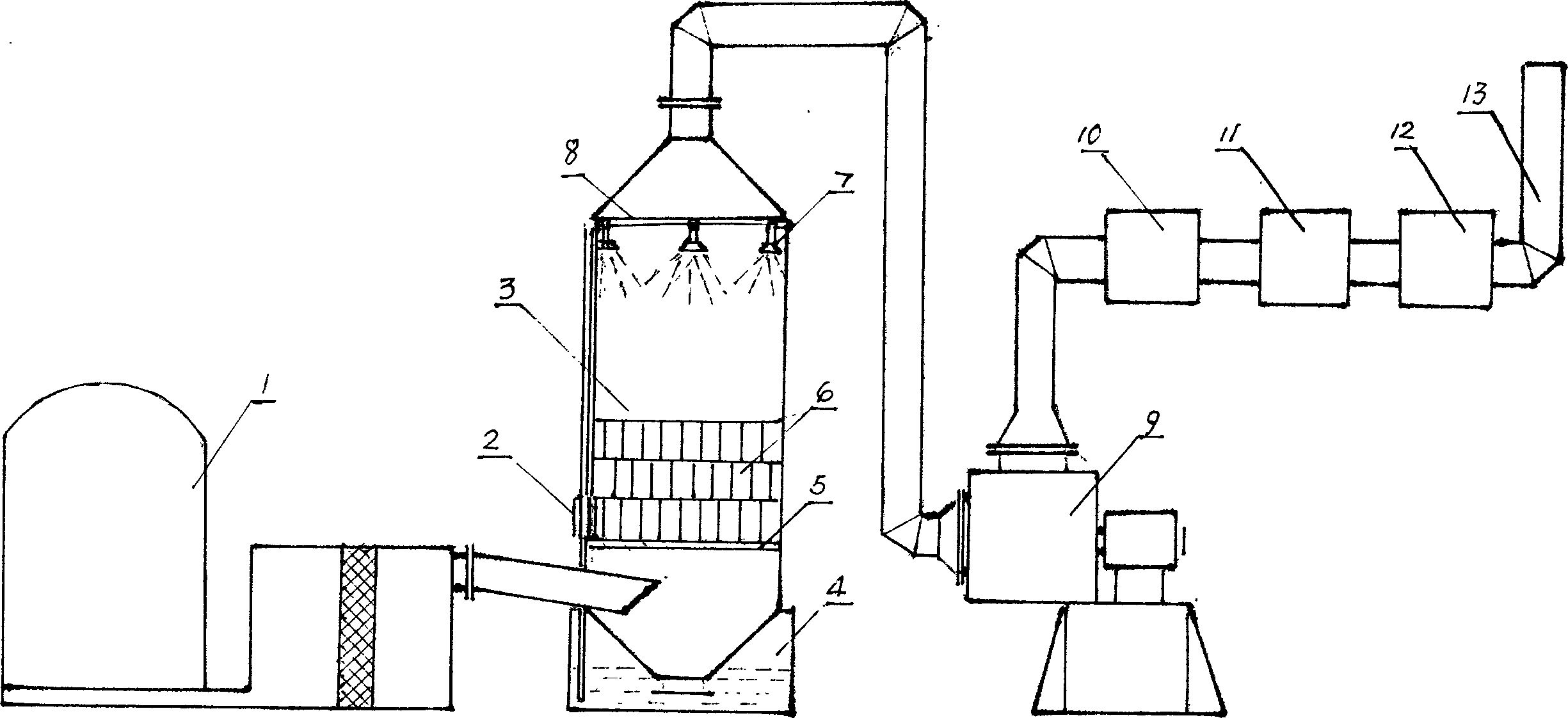

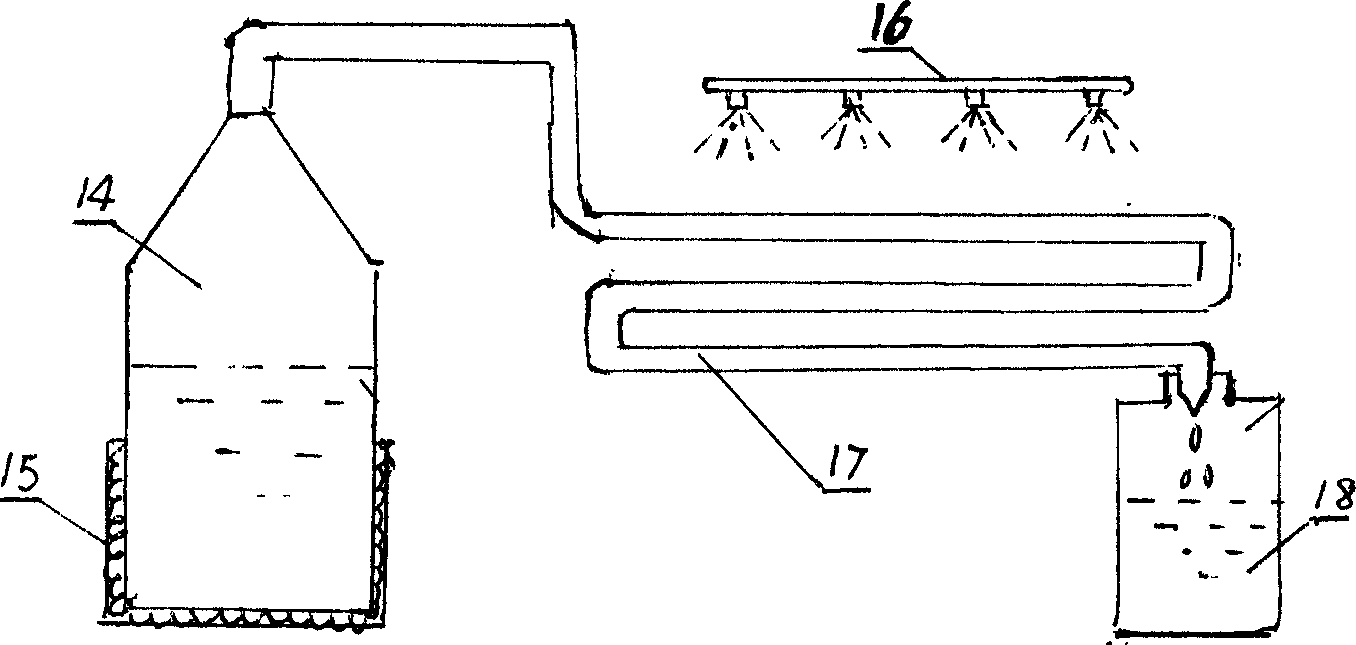

[0016] Examples are attached figure 1 As shown in the process of treating the toxic waste gas produced in the painting process, the waste gas is pumped from the paint spraying room 1 into the packing absorption tower 3, and is circulated and absorbed by washing oil under negative pressure: that is, the washing oil is pumped from the oil storage tank 4 by the oil pump 2 The annular oil pipe 8 pumped to the top of the tower is sprayed out from the nozzle 7, contacts with the waste gas entering from the bottom of the tower, and increases the contact with the ceramic ring packing 6 to achieve the purpose of mass transfer, remove most of the toxic components or pass through the sieve plate 5 Flow back to the oil storage tank 4; the absorbed waste gas is extracted by the fan 9, enters the activated carbon adsorber 10 and the activated clay adsorber 11 in turn, and finally enters the glass fiber filter 12, and the tiny liquid droplets in the exhaust gas are filtered out and discharged...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap