Formaldehyde, methanol and N,N dimethyl hydroxyamine coexisting anlytical method

A technology of dimethylhydroxylamine and analysis method, which is applied in the field of qualitative and quantitative analysis, and can solve problems such as analysis that has not been reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

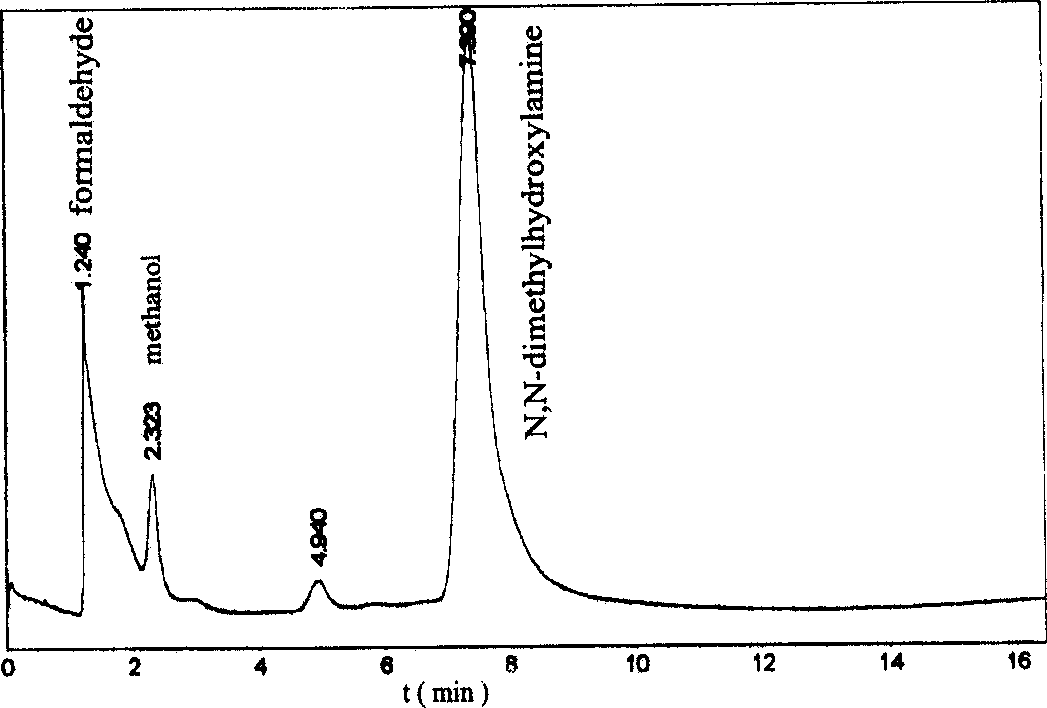

[0025] The analysis process and steps in this embodiment are described as follows:

[0026] (1) Prepare a simulated sample and prepare a mixed solution containing formaldehyde, methanol and N,N-dimethylhydroxylamine;

[0027] (2) Using gas chromatography using GDX-401 packed column (φ3mm×2m) combined with a hydrogen flame ionization detector, correctly load the GDX-401 packed column into the chromatograph, vent nitrogen, and adjust its flow to 20ml / After 20 minutes, let air pass and adjust the flow to 300ml / min; set the column temperature to 130℃, the vaporization chamber temperature to 160℃, and the detector temperature to 160℃; the set gain is 10 9 , The attenuation is zero. Operating column temperature, vaporization chamber and detector temperature;

[0028] (3) When the hydrogen flame ionization detector reaches the set temperature of 160℃, vent hydrogen and adjust the hydrogen flow rate to 80ml / min: use an electronic ignition gun to ignite at the detector outlet, and then sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com