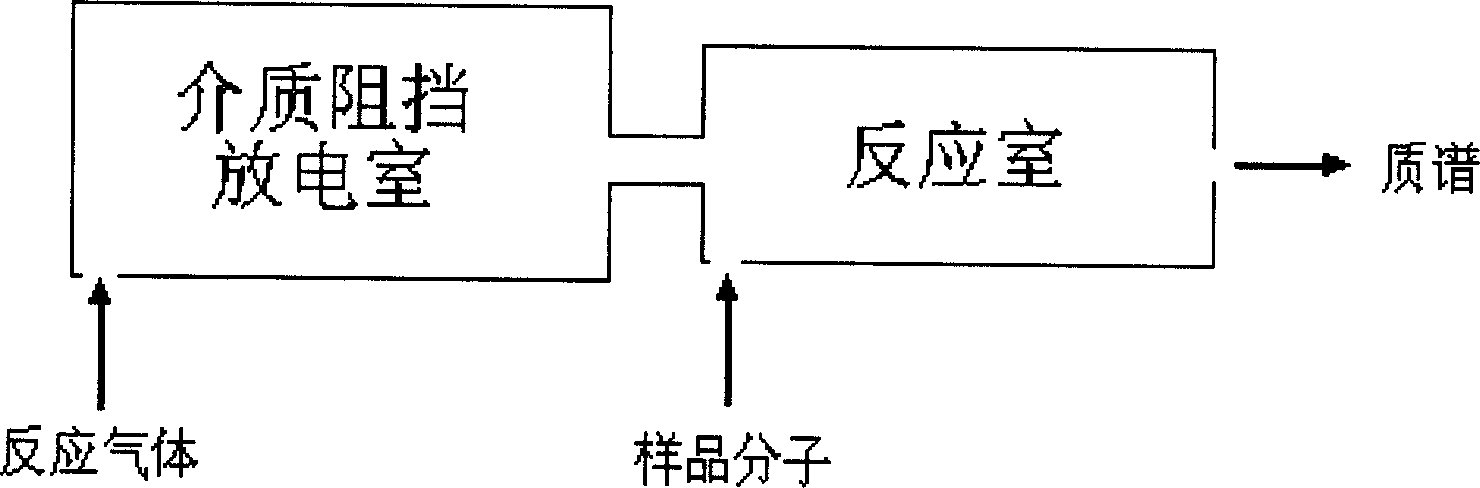

Chemical ioning method based on dielectric blocking discharge and mass ion source

A technology of dielectric barrier discharge and chemical ion, which is applied in the field of mass spectrometry ion source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

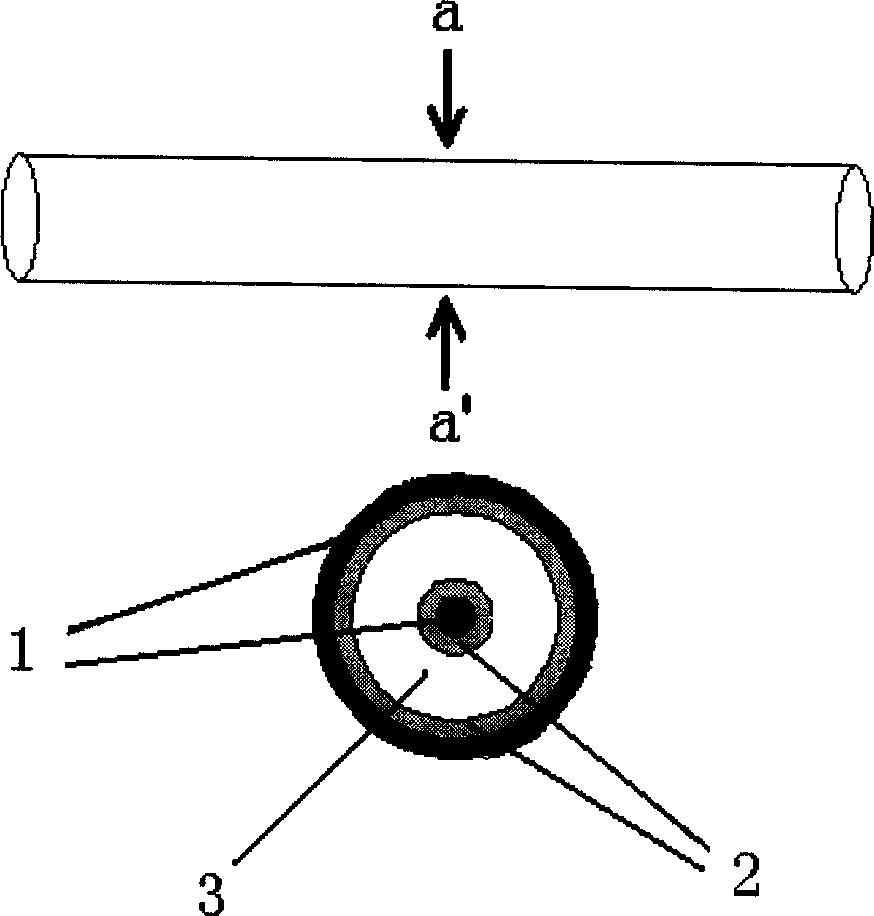

[0021] Implementation example 1. Select water vapor as the reaction gas, and pass it into the discharge chamber. The discharge chamber adopts a cylindrical structure, double-layer dielectric, the discharge channel (3) is 2 mm in height, and the discharge area length is 10 cm. The barrier medium (2) is Quartz (0.5mm) produces a stable discharge under the discharge voltage of 3000V and frequency of 20kHz. The water vapor flow rate is 10ml / min. The outlet current of the discharge chamber that can be measured with a nanoampere meter is: 10nA, indicating that a certain amount of discharge has been obtained. H 3 o + , introduce the air sample containing volatile organic compounds to be tested into the reaction chamber. H produced by discharge 3 o + That is, it undergoes a proton transfer reaction with volatile organic compounds in the air to ionize them, so as to achieve detection by mass spectrometry. The ion source has high sensitivity (ppbv level), wide linear range (more tha...

Embodiment 2

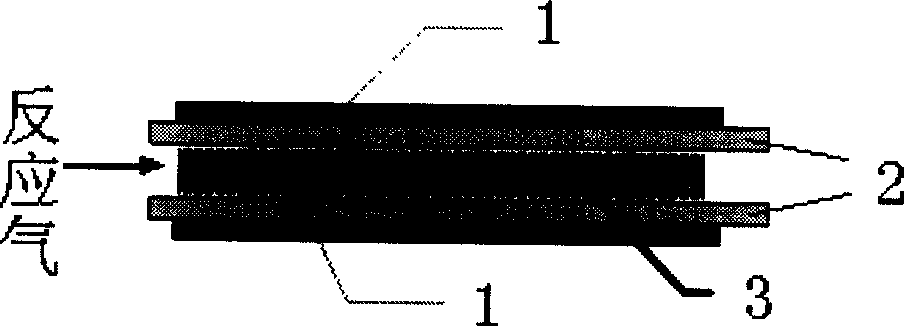

[0022] Implementation example two, select ammonia gas as the reaction gas, and pass it into the discharge chamber, the discharge chamber adopts a flat structure, double-layer dielectric, the discharge channel (3) is 0.5mm in height, and the discharge area length is 3cm, and glass is the barrier medium (2 ) (5mm), the discharge voltage is 220V, a stable discharge is produced under the condition of a frequency of 50MHz, and the ammonia flow rate is 300ml / min, and hexachlorobenzene is introduced into the reaction chamber. NH produced by discharge 4 + That is, ion-molecule reaction with hexachlorobenzene to ionize it, so as to realize detection by mass spectrometry.

Embodiment 3

[0023] Implementation example three, select methane gas as the reaction gas, and pass it into the discharge chamber, the discharge chamber adopts a flat plate structure, double-layer dielectric, the discharge channel (3) is 10mm in height, and the discharge area length is 20cm, and alumina ceramics is the barrier medium ( 2) (1mm), the discharge voltage is 10000V, a stable discharge is generated under the condition of frequency 50Hz, the flow rate of methane is 1000ml / min, and porphyrin is introduced into the reaction chamber. The ions generated by the discharge will react with the porphyrin molecules to ionize them, so that they can be detected by mass spectrometry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com