Reed lumber production process

A technology for plate production and reed, applied in the field of reed plate production technology, can solve the problems of low plate strength, deteriorating production conditions, heavy weight, etc., and achieve the effect of simple process method, no environmental pollution, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

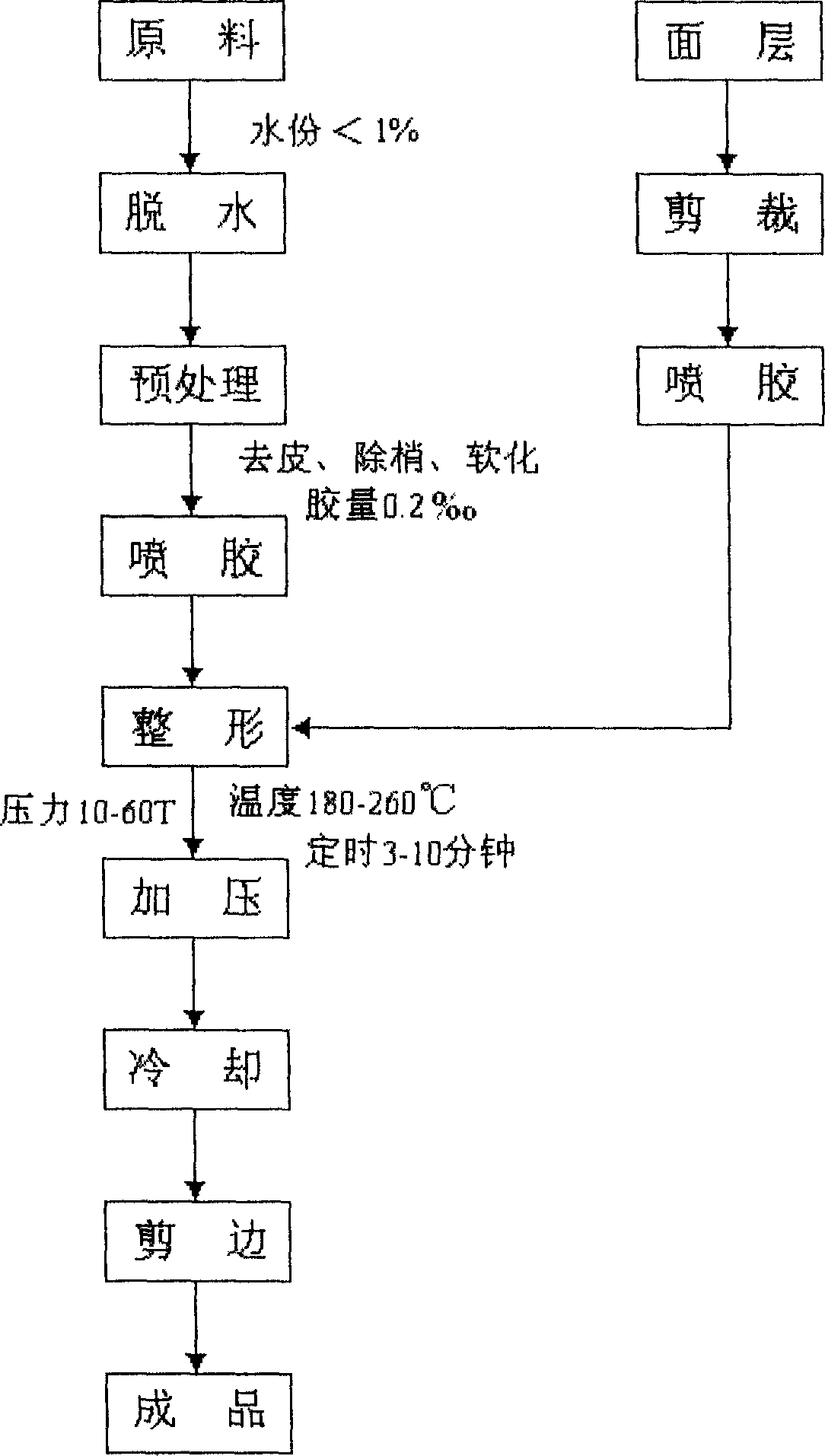

Method used

Image

Examples

Embodiment 1

[0017] First, dehydrate and dry the raw reeds, or dry them in the air, so that the water content is less than 1%; then enter the pretreatment process, and send the reeds to a self-made double-roller for rolling, which can be rolled once or rolled Press 2 or 3 times; before rolling, the tubular reed stalk should be broken into two halves that are connected together, and then the reed stalk will be peeled, tipped and softened through the double-roller machine, and the reed softened by the double-roller machine will form Sheet-shaped, or thick and thin fibers, long strip-shaped blanks connected to each other; in the glue spraying process, the surface of the blank is sprayed with phenolic resin glue with a spray gun, and the amount of glue used is controlled at 0.2 kg of the total amount of blanks per kilogram ;The surface layer raw material adopts 120g facial paper with colored patterns; or, adopts 0.6mm thick wood veneer; After the first layer of glue spraying, transfer to the s...

Embodiment 2

[0019] The raw reeds are dried to make the water content <1%. The reason is to ensure that the board does not foam during the pressing process; the glue spraying process uses urea-formaldehyde resin; ;The surface layer is made of 180g color pattern paper, or 1mm thick wooden skin; the blank layer has 26 layers in total, and the thickness of the formed plate is 15mm; Control at 240°C for 8 minutes; other process conditions are the same as in Example 1, and qualified reed boards can also be produced.

Embodiment 3

[0021] Reeds are used to produce composite panels for decoration. After the reeds are dehydrated, pretreated, and sprayed with glue, they enter the shaping process, and the blanks are compiled into a reed mat shape, with a total of 50 layers arranged up and down, and the thickness of the board is 30mm; the colored kraft paper for the surface layer is 220g, or 2mm thick wooden skin; The pressing process presses 4 boards at a time, the pressure is 60T, the temperature is 260° C., and the time is controlled at 10 minutes; other process conditions are the same as in Example 1, and qualified reed boards can also be produced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com