Method for extracting multiple liquorice flavone form liquorice

A technology of licorice and licorice glycosides is applied in the new field of extracting and purifying various licorice flavonoids from licorice, which can solve the problems of low yield, long production cycle, environmental pollution and the like, and achieve the effects of reducing production costs and saving organic solvents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

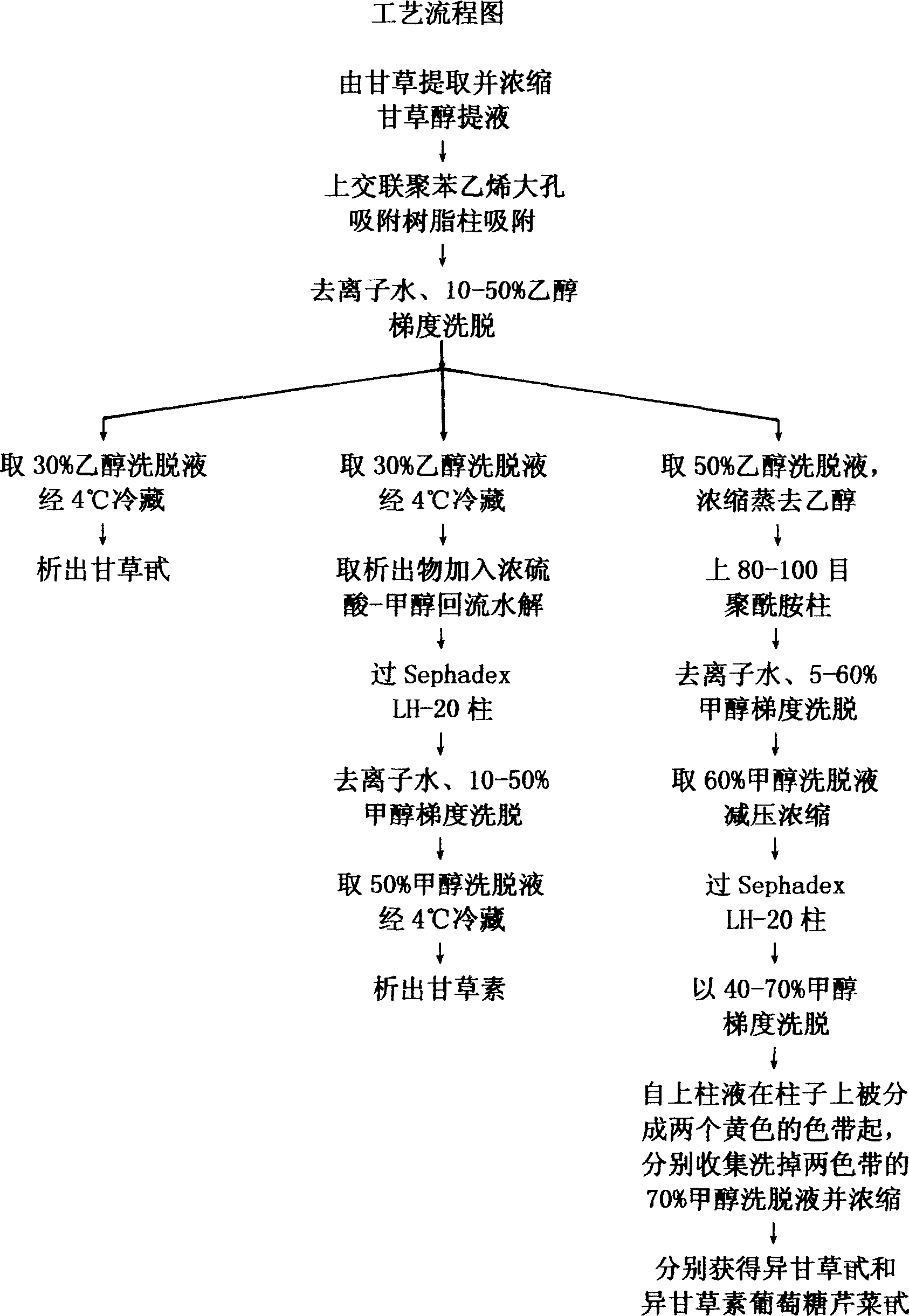

[0024] Embodiment one (referring to accompanying drawing " process flow diagram "):

[0025] Take 1kg of Ural licorice and grind it into 10000mL of 70% ethanol for ultrasonic extraction at room temperature twice, each time for 30min, coarsely filter with 200 mesh nylon filter cloth, centrifuge at 5,000rmp for 10min, and concentrate the centrifuged supernatant under reduced pressure (0.05MPa, 50℃ ), evaporate ethanol to 1 / 10 volume, take the concentrated supernatant and adsorb on a macroporous resin column (filled with cross-linked polystyrene resin), and successively elute with water and 10-30% ethanol gradient, and the elution flow rate is 1.5BV / h. Use HPLC or TLC to detect the effluent, and wash until the main substance cannot be detected in the effluent. Take 30% ethanol eluate and refrigerate at 4°C to precipitate 14g of liquiritin.

Embodiment 2

[0026] Embodiment two (referring to accompanying drawing " process flow diagram "):

[0027] Take 1 g of liquiritin obtained in the previous example, put it into 50 ml of aqueous solution containing 5% concentrated sulfuric acid and 40% methanol for reflux hydrolysis for 1.5 hours, concentrate under reduced pressure (0.05MPa, 50°C), and distill off the methanol to 1 / 10 volume , passed through a Sephadex LH-20 column, eluted with water and 10-50% methanol under normal pressure in sequence, and used HPLC or TLC to detect the effluent, and washed until the main substance could not be detected in the effluent. The 50% methanol eluate was refrigerated at 4°C, and 0.25 g of white needle crystals of liquiritigenin was precipitated.

Embodiment 3

[0028] Embodiment three (referring to accompanying drawing " process flow diagram "):

[0029] Take 1 kg of Ural licorice and grind it into 10,000 mL of 80% ethanol for ultrasonic extraction at room temperature twice, each time for 30 min, filter with a 200-mesh nylon filter cloth, centrifuge at 5,000 rpm for 10 minutes, and concentrate the centrifuged supernatant under reduced pressure (0.05 MPa, 50 °C ), evaporate ethanol to 1 / 10 volume, take the concentrated supernatant and absorb it on a macroporous resin column, and then elute with water and 10-50% ethanol gradient successively, get 50% ethanol eluate, concentrate and evaporate ethanol, the concentrated solution Put on a polyamide column of 80-100 mesh, eluted with water and 5-60% methanol at normal pressure gradient successively, take 60% methanol eluate and concentrate under reduced pressure, pass through Sephadex LH-20 column, and elute with 40-70% methanol at normal pressure gradient Elution starts from the upper colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com