Light emitting device and electronic appliance using the same

A technology of emission device and electron, applied in lighting device, electroluminescence light source, application, etc., can solve the problem of low manufacturing margin and achieve the effect of low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0039] Although the present invention has been described in detail with reference to the accompanying drawings, it should be understood that various changes and modifications will be apparent to those skilled in the art. Therefore, unless otherwise these changes and modifications depart from the scope of the present invention, they should be construed as being included therein. Therefore, the present invention should be construed as not limited to the description of the embodiments given below.

Embodiment approach 1

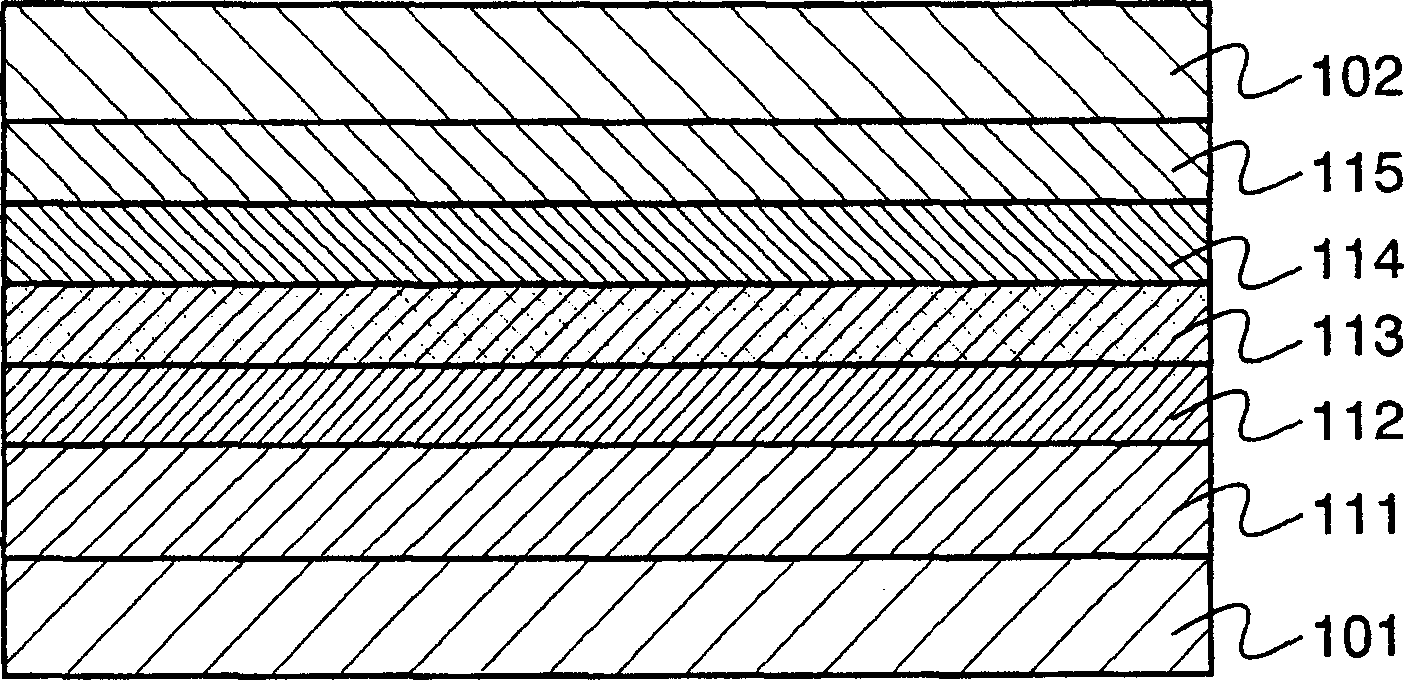

[0041] combine figure 1 One embodiment of the light-emitting element of the present invention will be described.

[0042] figure 1 A light emitting element including a light emitting layer 113 between a first electrode 101 and a second electrode 102 is shown. In addition, a first mixed layer 115 containing an electron transport substance and a substance exhibiting electron donating properties to the electron transport substance is provided between the light emitting layer 113 and the second electrode 102 . In addition, on the side of the light-emitting layer 113 close to the first electrode 101, the hole transport layer 112 in contact with the light-emitting layer 113 is formed, and on the side of the light-emitting layer 113 close to the second electrode 102, the hole transport layer 112 in contact with the light-emitting layer 113 is formed. transfer layer 114 . noticed figure 1 The light emitting element in has a hole injection layer 111 disposed between a first electro...

Embodiment approach 2

[0077] The synthesis method of the organometallic complex used in the practice of the present invention will be described below. Note that the synthesis method is not limited to the method disclosed here, and other synthesis methods may be employed.

[0078] The organometallic complex of the present invention represented by any one of Structural Formula (8) - Structural Formula (31) is obtained by a synthesis method such as represented by Synthesis Route (a-1) - Synthesis Route (a-3). Ligands with electron-withdrawing groups were synthesized via the synthetic route (a-1). Subsequently, the synthesized ligand having an electron-withdrawing group is mixed with iridium(III) chloride hydrochloride hydrate, as shown in the synthesis scheme (a-2), to coordinate the ligand to iridium. In addition, a monoanionic ligand is coordinated to iridium as shown in the synthetic scheme (a-3).

[0079]

[0080]

[0081] Here, R in the synthetic route (a-1) to the synthetic route (a-3) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com