Absorbent and method for separating acid gases from gas mixture

A technology of mixing gas and acid gas, applied in the field, can solve the problems of strong corrosiveness, high alkalinity, strong ammonia smell and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

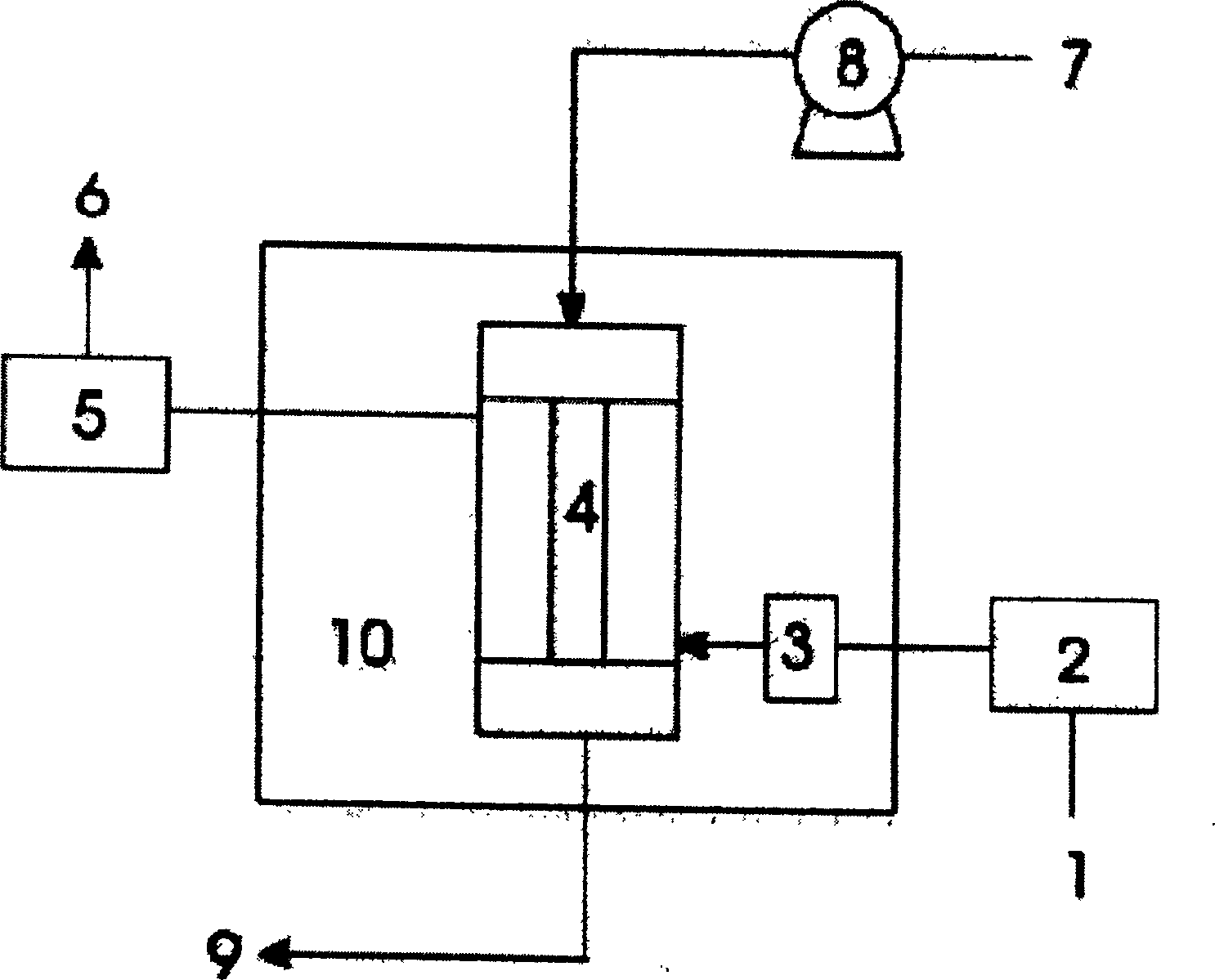

Image

Examples

experiment example 1

[0024] Experimental Example 1: Comparison of Alkalinity

[0025] Alkalinity is used to represent a measure of the ability to neutralize acid when it flows into an alkaline or a water system different from alkali. Hydroxide (OH - ), bicarbonate (HCO 3- ), carbonate (CO 3 2- )Wait. Base measurement is based on KS MISO9963-1.

[0026] Alkalinity of monoethanolamine (MEA) and sodium glycinate (SG) is indicated in the table below. It can be seen from Table 1 that the alkalinity changes little with temperature. In addition, the higher the concentration of monoethanolamine is, the higher the alkalinity is compared with sodium glycinate. Therefore, at the same concentration, the alkalinity of sodium glycinate is low, which can make it less corrosive.

[0027] 【Table 1】

[0028] Pilot projects

experiment example 2

[0029] Experimental example 2: Comparison of the unit absorption of carbon dioxide by each absorbent based on the temperature difference

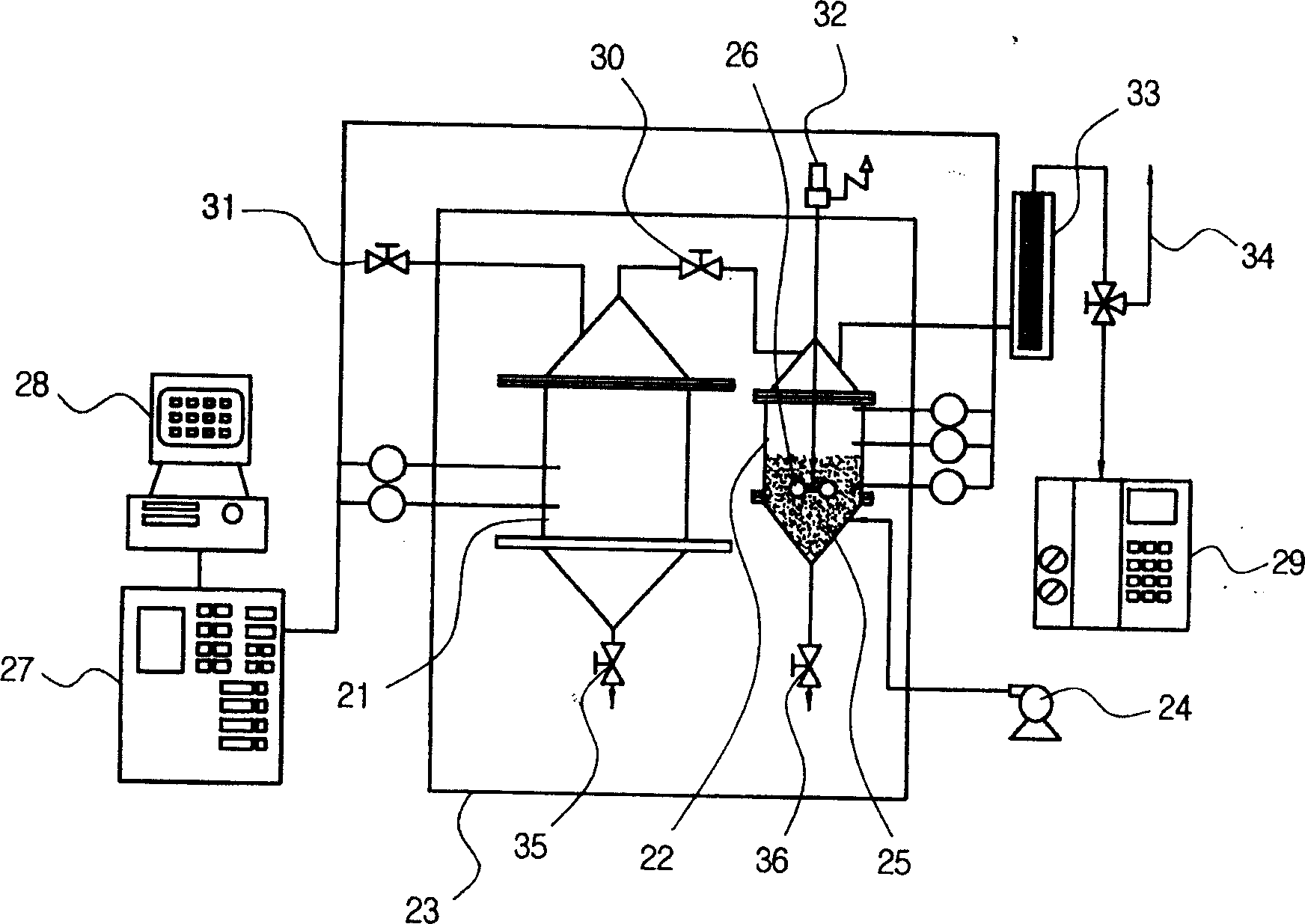

[0030] figure 2 for measuring the equilibrium CO of the absorbent at atmospheric pressure 2Schematic diagram of the experimental setup for uptake. The measuring device is composed of a storage tank 21 for injecting an accurate amount of carbon dioxide at a certain temperature, and a reaction tank 22 for reacting carbon dioxide and an absorbent at a certain temperature. In order to maintain a certain temperature, the above-mentioned device is set in a Forced Convection Oven (OF-22) from Zeeiotech Company. An accurate amount of absorbent is injected through a pump (Series 1; manufactured by Lab Alliance Co., Ltd.) 24. In order to make the absorbent 25 and carbon dioxide react smoothly, four baffles (baffles) 26 are installed in the reaction tank 22 for uniform mixing. . In the reaction tank 22, thermometers T are installed on both the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com