Perovskite oxide thin-film compound device

An oxide thin film and perovskite technology, applied in the field of perovskite oxide thin film composite devices, can solve problems such as being only suitable for large magnetic fields and low temperatures, and achieve the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1. Preparation of the first perovskite oxide thin film composite device I-1

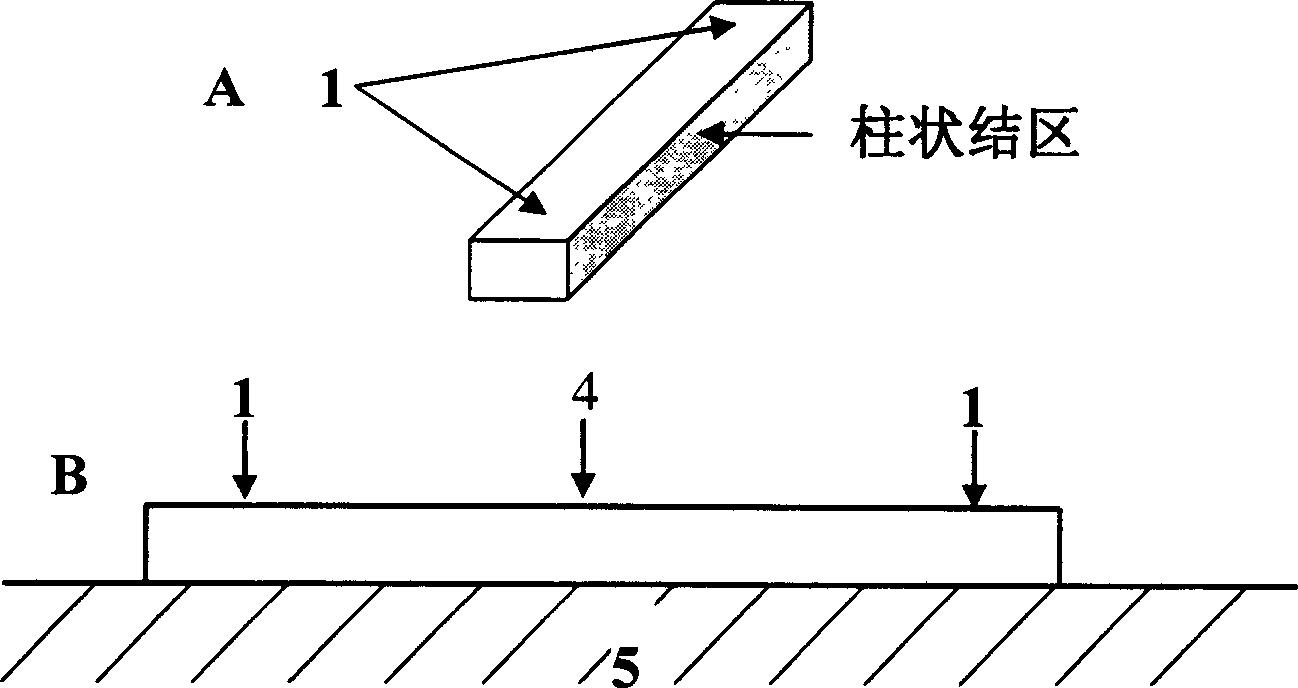

[0035] The first perovskite oxide thin film composite device I-1 provided by the present invention has a core structure as follows: figure 1 Shown in (1), it comprises: a MgO base substrate 5, on which a thickness of 2000nm perovskite oxide La is deposited. 0.1 Ca 0.9 MnO 3 The thin film layer 4, wherein the middle part of the thin film layer is a columnar junction area, and the two ends are the bottom electrode 1, that is, the lead-out end.

[0036] This composite device is realized through the following process: choose a MgO substrate as the substrate, and deposit a 2000nm-thick perovskite oxide monolayer film La by molecular beam epitaxy. 0.1 Ca 0.9 MnO 3 , and then use deep ultraviolet exposure to etch into a strip shape, and its two ends are used as lead-out ends, that is, the bottom electrode (0.5×0.5mm 2 ), middle part 0.2×2mm 2 It is the core part of the device, that is,...

Embodiment 2

[0038] Example 2. Preparation of the first perovskite oxide thin film composite device I-2

[0039] By the method in embodiment 1, with the La of 100nm 0.5 Ca 0.5 MnO 3 Instead of 2000nm La 0.1 Ca 0.9 MnO 3 .

Embodiment 3

[0040] Example 3, Preparation of the first perovskite oxide thin film composite device I-3

[0041] By the method in Example 1, with 1nm La 0.9 Ca 0.1 MnO 3 Instead of 2000nm La 0.1 Ca 0.9 MnO 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com