Exhaust gas treatment device and exhaust gas treatment method

A technology of exhaust gas treatment device and spray device, which is applied in the direction of separation method, chemical instrument and method, and separation of dispersed particles, which can solve the problems of ammonia hindering the operation cost and reducing the operating cost, so as to prevent the decrease of temperature, improve the removal efficiency, The effect of promoting evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

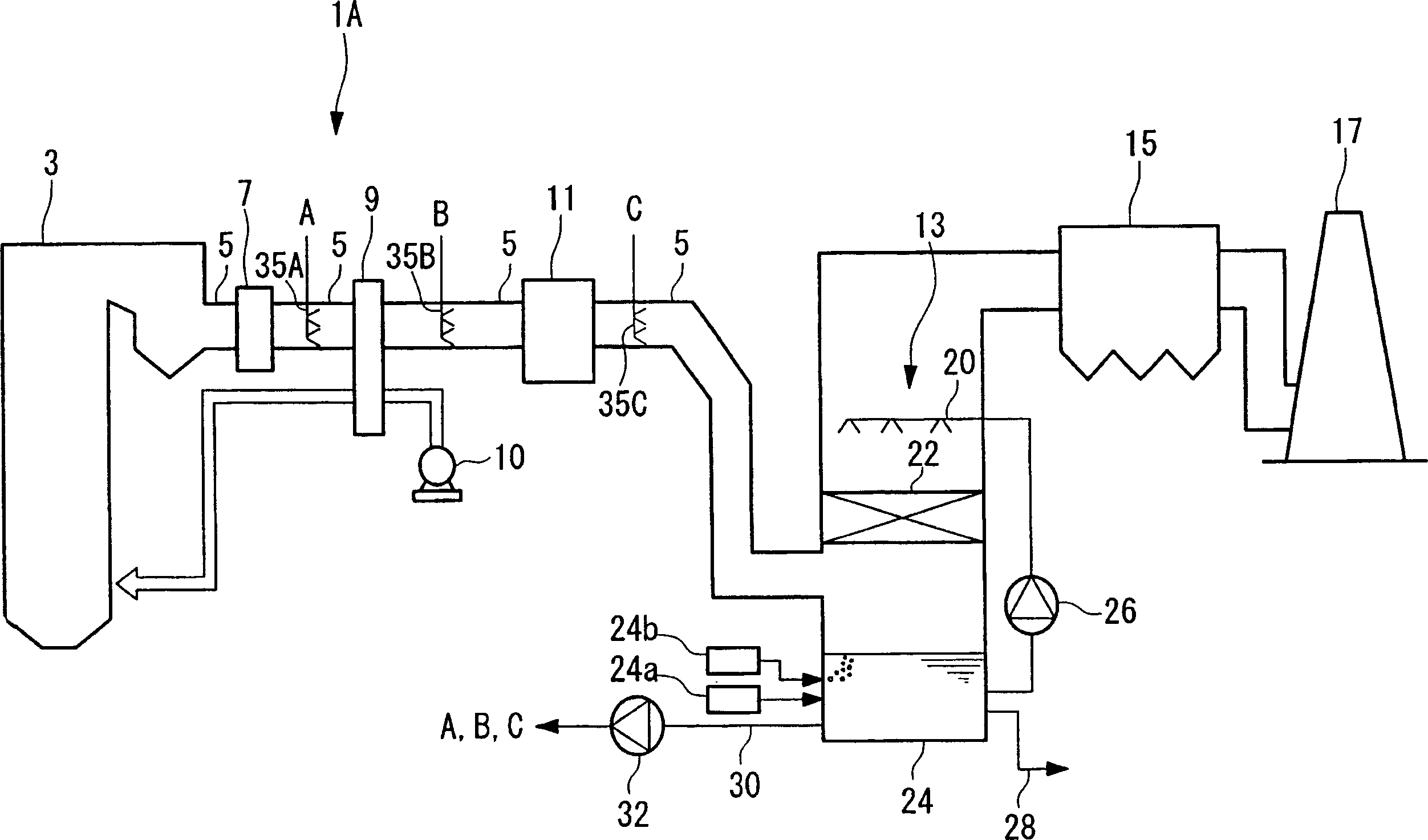

[0078] Below, use figure 1 The first embodiment of the present invention will be described.

[0079] This embodiment is an exhaust gas treatment device applicable to a wet desulfurization device using the caustic soda method.

[0080] figure 1 The exhaust gas treatment device according to this embodiment is shown.

[0081] The exhaust gas treatment device 1A has: a denitrification (denitration) device 7 installed in a flue 5 downstream of a boiler (combustor) 3 , an air heater 9 , a dry electric dust collector 11 , and a wet desulfurization device 13 , and dielectric gas cleaning device 15, and chimney 17.

[0082] The boiler 3 is a heavy oil combustion boiler that burns, for example, heavy oil containing a lot of sulfur.

[0083] The denitrification device 7 is a device for removing nitrogen oxides (NOx) contained in the combustion exhaust gas discharged from the boiler 3 .

[0084] The air heater 9 is a device for exchanging heat between combustion exhaust gas and combu...

no. 2 Embodiment approach

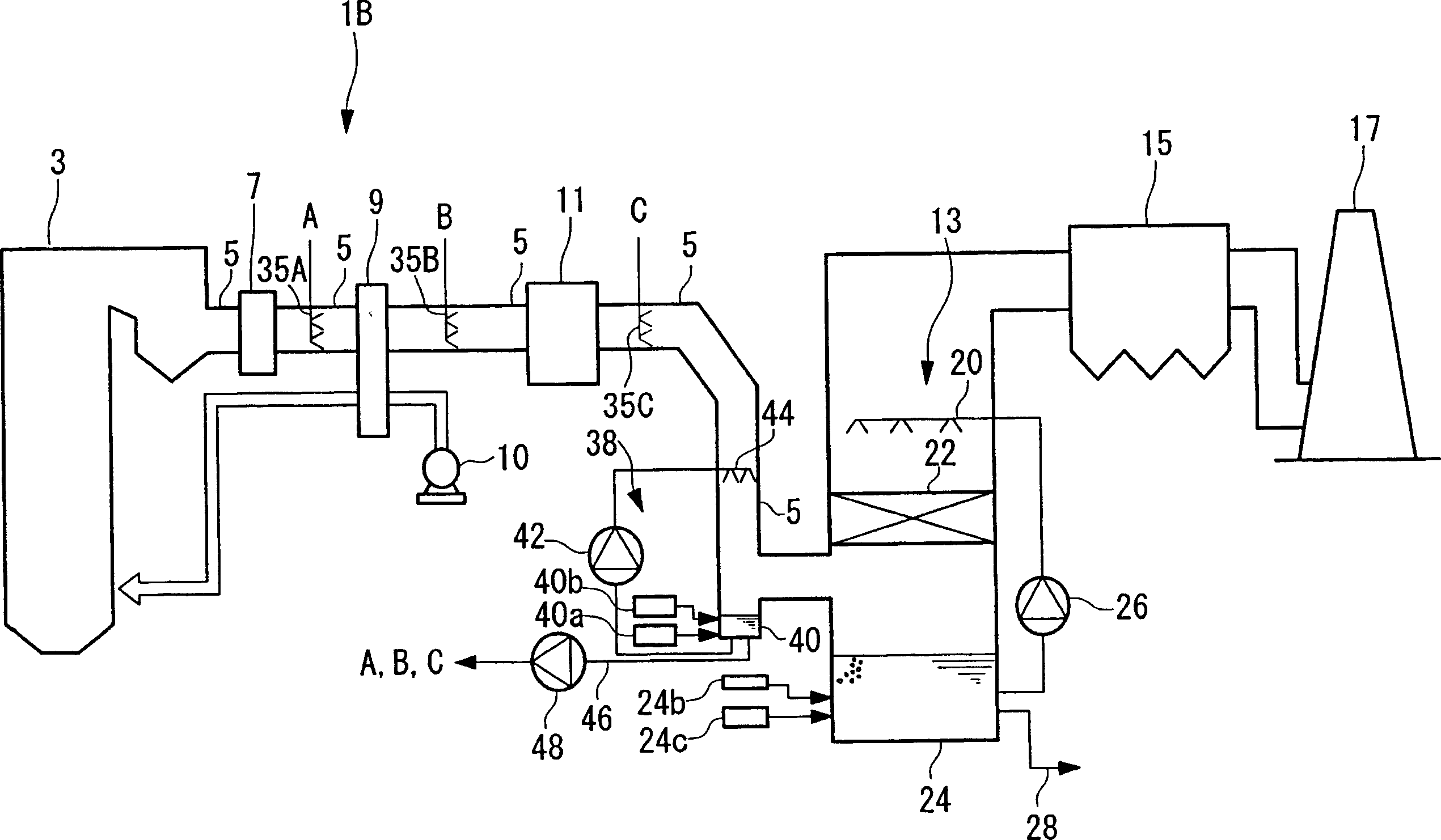

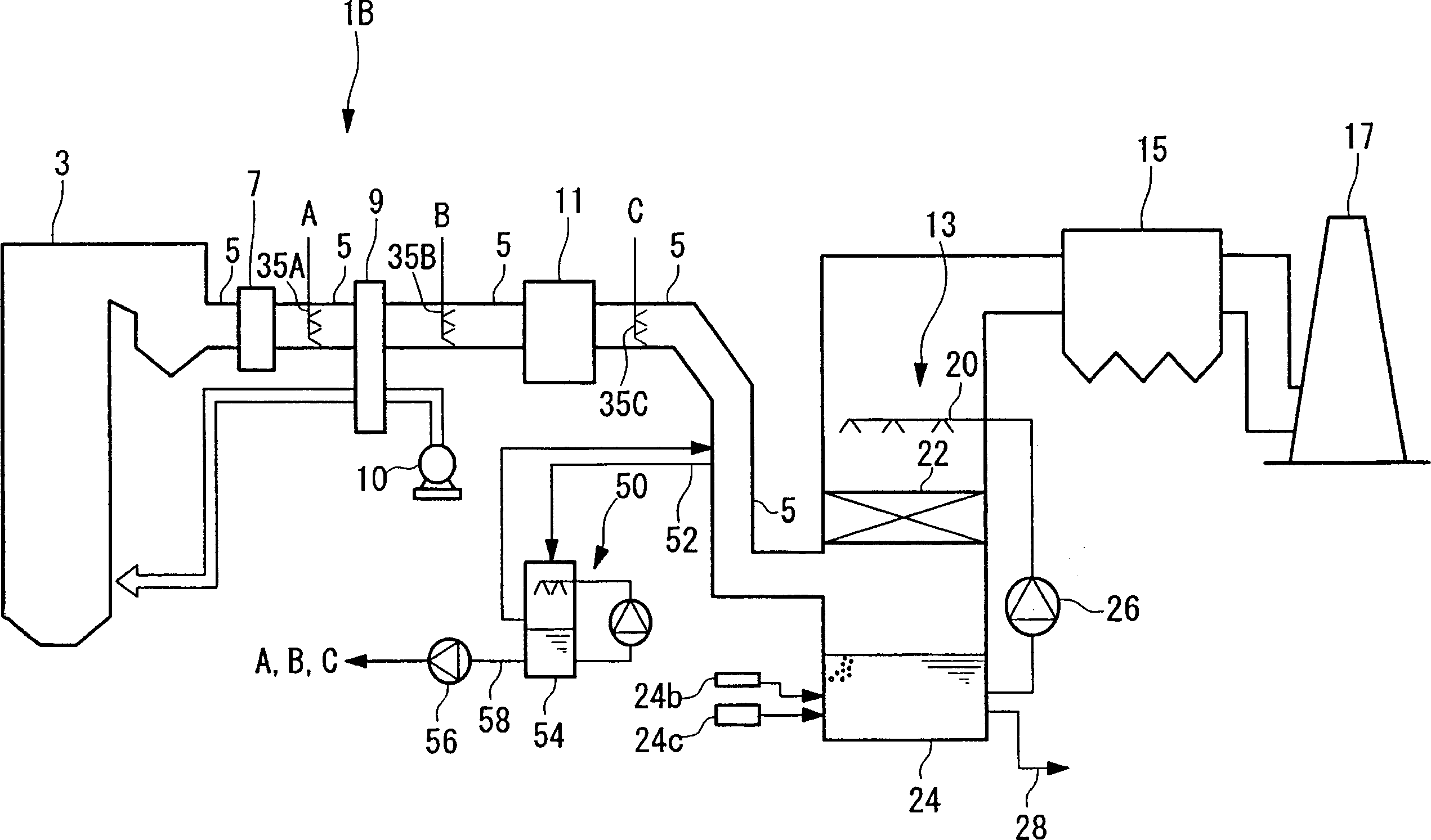

[0134] Next, use figure 2 A second embodiment of the present invention will be described.

[0135] This embodiment is an exhaust gas treatment device suitable for a wet desulfurization device using a lime-gypsum method.

[0136] In addition, the same code|symbol is attached|subjected to the same component as 1st Embodiment, and the description is abbreviate|omitted.

[0137] figure 2 The exhaust gas treatment device according to this embodiment is shown.

[0138] The exhaust gas treatment device 1B uses limestone (CaCO 3 ) as an absorbent to remove sulfur oxides. The product produced by the lime gypsum method is insoluble CaSO 4 , so it is difficult to remove SO using desulfurization wastewater as in the first embodiment 3 .

[0139] Here, in the present embodiment, a second wet desulfurization device 38 using the caustic soda method, which is smaller in scale than the wet desulfurization device 13 , is installed in the middle of the flue 5 . The second wet desulfuri...

Embodiment

[0148] use Figure 4 ~ Figure 6 , to remove SO 3 test will be described.

[0149] Figure 4 The outline of the test device is shown in .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com