Method for producing sodium sulfhydrate

A sodium hydrosulfide and production method technology, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve the problems affecting the quality and use of sodium hydrosulfide products, inconvenient use, easy to puncture the product, etc., to achieve easy Implementation, not easy to stick, good fluidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

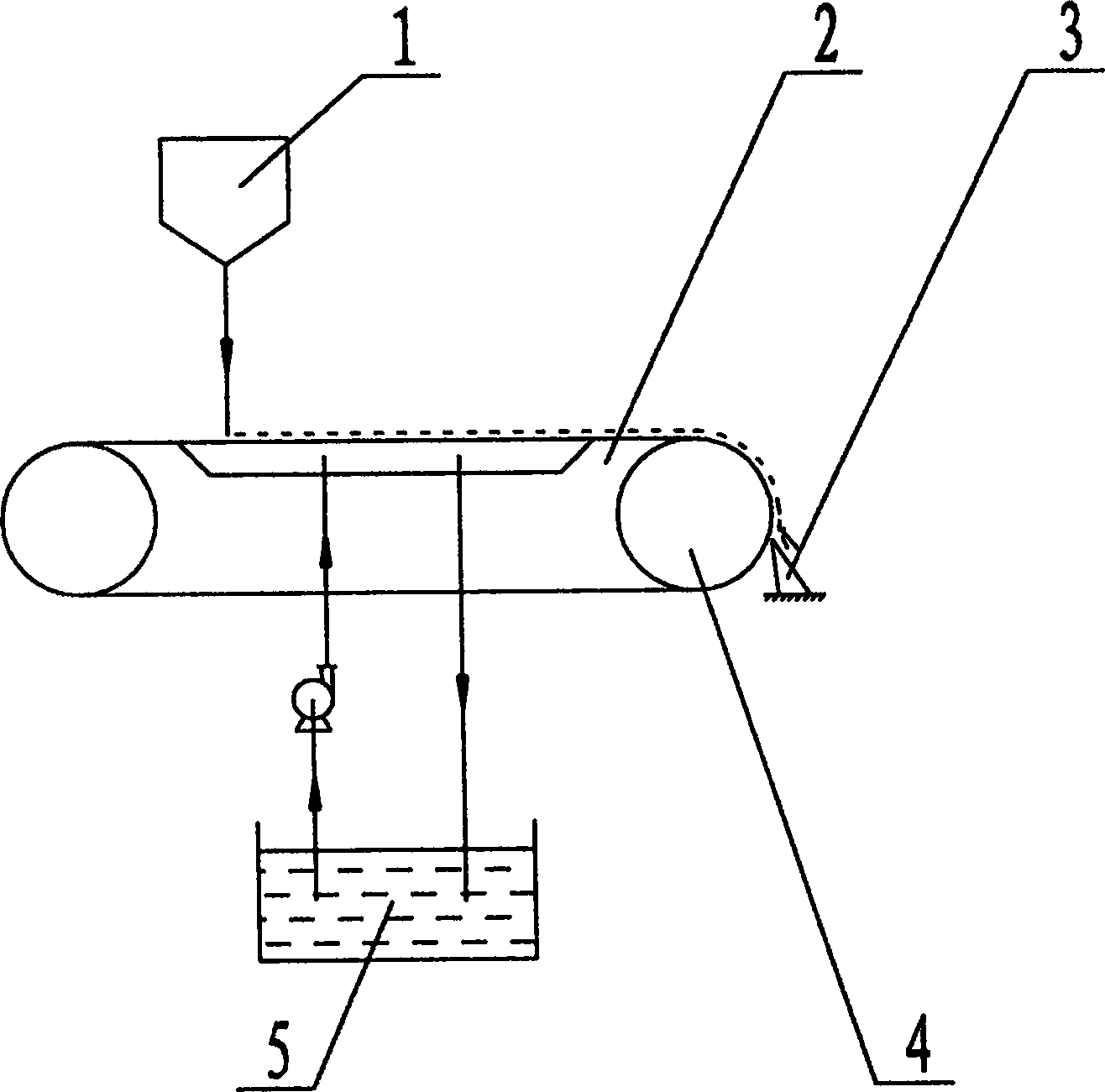

[0011] As shown in the figure, the sodium hydrosulfide aqueous solution is concentrated to 65-90% content by common methods. The sodium hydrosulfide solution in (1) drips onto the rotary belt (2) from the bottom hole, and the rotary belt (2) moves at a constant speed under the action of the rotating system (3), and a circulating cooling water is installed at the lower part of the rotary belt (2) System (4), the cooling water makes the sodium hydrosulfide on the rotary belt (2) gradually cool and solidify into shape, the temperature of the cooling water is ≯25°C, and the sodium hydrosulfide is separated when the rotary belt (2) turns to bend, and it can also be arranged on the rotary belt ( 2) Turn to the scraper (5) on the front lower side of the bend to scrape off the sodium hydrosulfide, then use conventional methods to bag and seal the sodium hydrosulfide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com