Composite water treating agent for industrial circulation cooling water

A technology of circulating cooling water and water treatment agent, used in water/sludge/sewage treatment, complex/solubilizer treatment, scale removal and water softening, etc., to achieve excellent high temperature scale inhibition performance and zinc stabilization ability, increase The effect is obvious and the stability is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

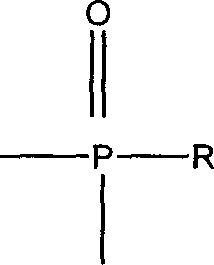

Image

Examples

Embodiment 1

[0018] The preparation of composite water treatment agent: with 5mg phosphine carboxylic acid copolymerization compound, 5mg sodium molybdate (as MoO 4 2- meter), 3mg benzotriazole (BTA), 1mg cerium nitrate, 1mg ZnSO 4 ·H 2 O (in Zn 2+ meter) and 1L of water are placed in a stirring container and mixed uniformly, which is the normal water treatment agent of the present invention.

Embodiment 2

[0020] The preparation of composite water treatment agent: with 3mg phosphine carboxylic acid copolymerization compound, 5mg sodium molybdate (as MoO 4 2- meter), 3mg benzotriazole (BTA), 0.5mg lanthanum nitrate, 1mg ZnSO 4 ·H 2 O (in Zn 2+ meter) and 1L of water are placed in a stirring container and mixed uniformly, which is the normal water treatment agent of the present invention.

Embodiment 3

[0022] The preparation of composite water treatment agent: with 3mg phosphine carboxylic acid copolymerization compound, 3mg sodium molybdate (as MoO 4 2- meter), 3mg benzotriazole (BTA), 1.5mg praseodymium nitrate, 1mg ZnSO 4 ·7H 2 O (in Zn 2+ meter) and 1L of water are placed in a stirring container and mixed uniformly, which is the normal water treatment agent of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com