Process for producing hydroxyacetic acid by microbiological method

A glycolic acid and microbial method technology, applied in the direction of microorganism-based methods, microorganisms, biochemical equipment and methods, etc., can solve the problems of polluted environment, complex process, low conversion rate, etc., and achieve high product quality, low energy consumption, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

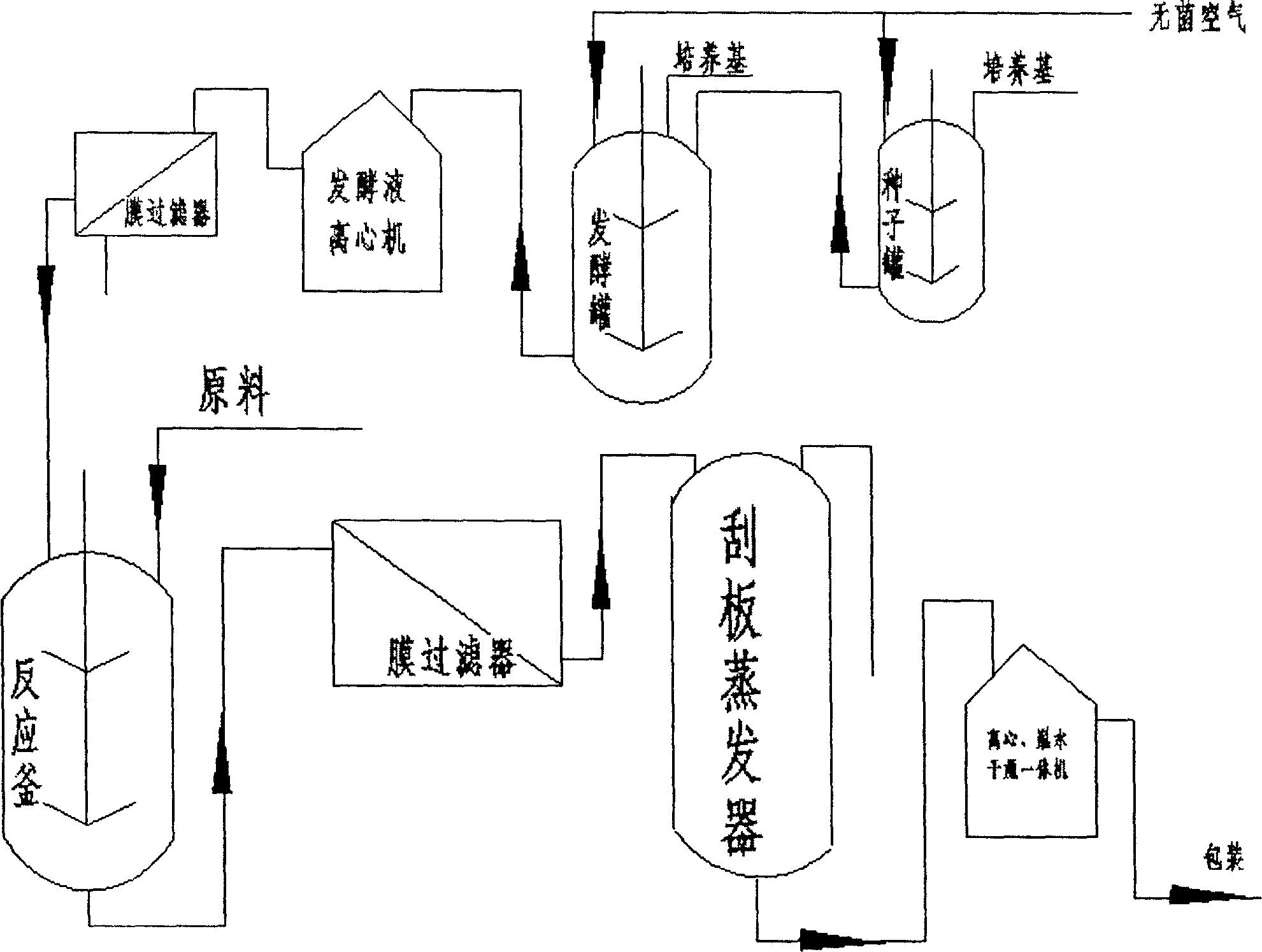

[0013] With reference to accompanying drawing, its detailed technical scheme comprises as follows:

[0014] (1) Screening of enzyme-producing cell strains

[0015] The nitrile hydratase with strong acid production ability is screened from the strains of Corynebacterium propionici, and then the strains with high enzyme production are screened for cultivation and amplification.

[0016] (2) Preparation of enzyme-producing cells

[0017] Add an appropriate amount of seed medium (10%-50%) into the triangular flask, insert the strains (about 5%) after sterilization, and culture at 20°C-40°C in a rotary shaker at 100-600rpm for 50-120°C. Hours, bottled for later use. Add an appropriate amount of seed culture medium (10%-50%) in the seed tank, insert the above-mentioned bacterial strains for bottling after sterilization, and at a temperature of 20°C-40°C, the ventilation rate is 1: 0.2-1 : 1 (V.V.M); Stirring speed: 50-400rpm, tank pressure 0.04-0.06, ferment for 50-120 hours; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com