Two-component polyurithane compound exhibiting a high early strength

A two-component polyurethane, polyurethane prepolymer technology, used in polyurea/polyurethane adhesives, adhesive types, adhesives, etc., can solve the problems of high initial strength and long processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

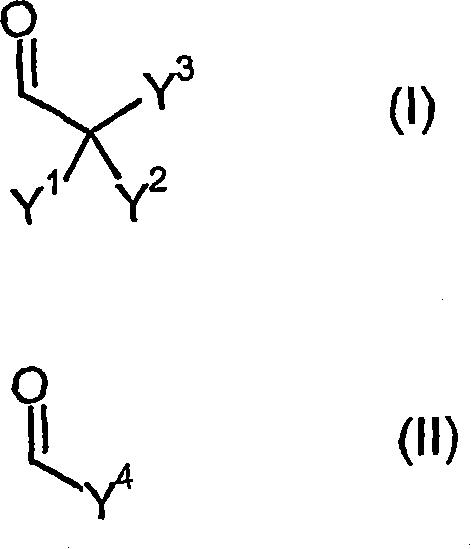

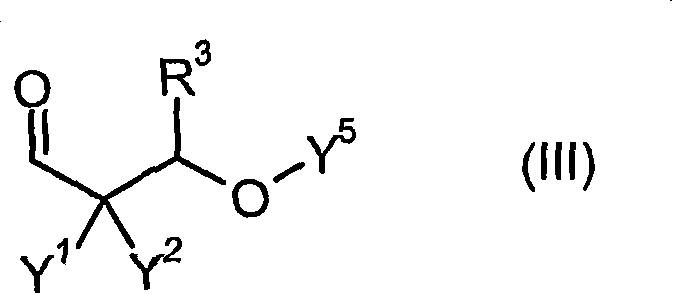

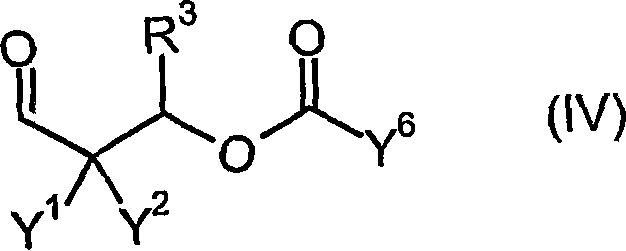

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0172] Embodiment 1 (component A)

[0173] In a vacuum mixer, 3400 g of polyurethane prepolymer A1, prepared as follows: 1402 g of diisodecyl phthalate (DIDP), 14 g of p-tolylsulfonyl isocyanate (Zusatzmittel TI , Bayer), 21g 3-glycidoxypropyltrimethoxysilane (Silquest A-187, OSi Crompton), 1052g calcined kaolin, 1052g carbon black and 7g di-n-butyltin dichloride (1.8% in DIDP), processed to a lump-free, homogeneous Paste, and stored under the exclusion of moisture. The material has an isocyanate group content of 0.241 mmol NCO / g and a density of 1.23 g / cm 3 .

[0174] After complete curing of the first component A only by means of atmospheric moisture at 23° C. and 50% relative air humidity, it has

[0175] Shore A-hardness of 47,

[0176] The tensile strength is 7.4MPa, and

[0177] The elongation at break was 310%.

[0178] Polyurethane prepolymer A1 was prepared as follows:

[0179] 1290g polyol Acclaim 4200N, 2580g Polyol Caradol MD34-02, 630g 4,4'-methy...

Embodiment 2 to 17

[0181] Examples 2 to 17 (Component B)

[0182] In a vacuum mixer, the components given in Tables 2a and 2b were mixed under exclusion of moisture and processed to form a lump-free homogeneous paste, which was stored under exclusion of moisture.

[0183] The density of component B of examples 2 to 17 corresponds to the density of component A of example 1, except for examples 5 and 14.

[0184] In Tables 2a and 2b, "DIDP" means diisodecyl phthalate, "DOA" means dioctyl adipate, and "kaolin" means calcined kaolin. "Tin catalyst"means a 1.8% solution of di-n-butyltin dichloride in DIDP.

[0185] "Ketimine" in Table 2b and Table 7 means polyketimine formed from 3,3,5-trimethyl-5-aminomethylcyclohexylamine (IPDA) and methyl ethyl ketone. Preparation was carried out as described in US 4108842 as "Curing Agent 1". Its ketimine content determined by amine content is 3.37mmolNH 2 / g, and has a strong pungent solvent odor.

[0186] Example

[0187] Example

[018...

Embodiment 24

[0203] Example 24 differs from Example 20 in the polyaldimines used, in which case the same aldehyde is reacted with two different polyamines. Although the different amines have no major influence on the mechanical properties of the final product, they have more influence on the development of green strength: the green strength develops significantly faster in Example 24 than in Example 20 at similar open times Construct. Both examples cured with neither bubbles nor detectable odors.

[0204] Example

[0205] "n.b." means "not determined"

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of unsaturation | aaaaa | aaaaa |

| degree of unsaturation | aaaaa | aaaaa |

| degree of unsaturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com