Nano particle synthesizing process

A synthesis method and nanoparticle technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems that the size distribution of nanoparticles cannot be well controlled, the effective contact area is not ideal, etc., and achieve ideal size and distribution, The effect of increased contact area and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

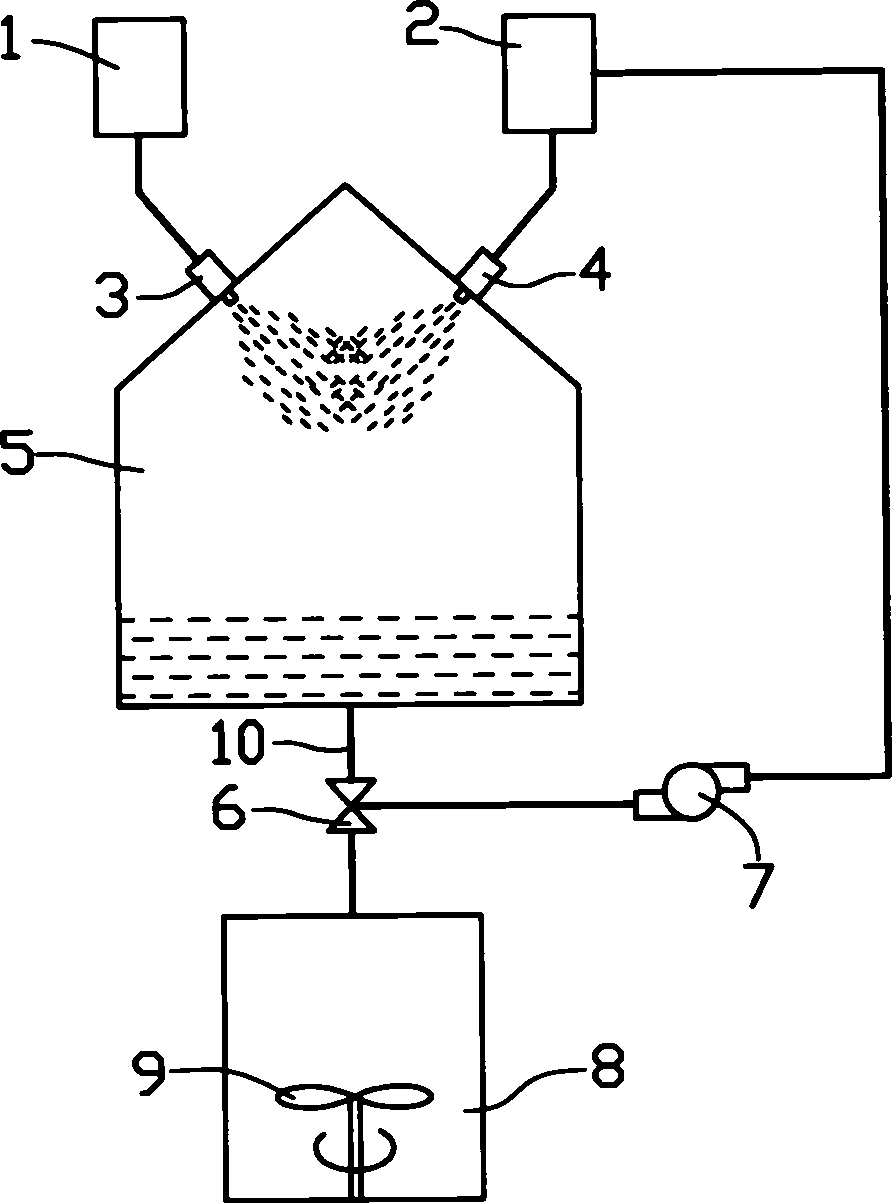

[0011] Please refer to figure 1 Shown, embodiment one of the present invention is to synthesize strontium carbonate (SrCO 3 ). The device that it adopts comprises a reaction chamber 5, container 1,2, atomizing nozzle 3,4, collection bottle 8, agitator 9, vacuum valve 6, vacuum pump 7 and a plurality of conduction pipes 10; Atomizing nozzle 3, 4 are respectively fixed on the side wall of the reaction chamber 5 at a certain angle, the containers 1 and 2 are respectively connected to the atomizing nozzles 3 and 4 through the conduction pipes, the collecting bottle 8 is equipped with a stirrer 9, and the collecting bottle 8 is placed At the bottom of the reaction chamber 5 and connected to the reaction chamber 5 through a conduit 10, the collection bottle 8, the vacuum valve 6, the vacuum pump 7 and the container 2 are sequentially connected through a conduit.

[0012] The reactant used in this embodiment is strontium nitrate (Sr(NO 3 ) 2 ) solution and sodium carbonate (Na 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com