Angiotensin converting enzyme inhibitory peptide production method

A technique for angiotensin, inhibitory activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

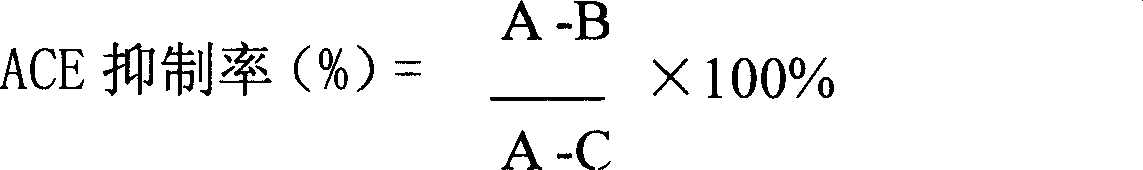

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1, a kind of production method of angiotensin-converting enzyme inhibitory active peptide, carries out following steps successively:

[0037] 1), after mixing rice grains and distilled water in the container according to the weight ratio of 1:4.13, adjust the pH value to 8.02 with a sodium hydroxide solution with a concentration of 2.5M;

[0038] 2), after adding trypsin into the container, put it into a constant temperature water bath for enzymolysis reaction; the temperature of the water bath is 37°C, the reaction time is 4 hours, and the amount of trypsin is 1.5% of the weight of rice grains;

[0039] 3), and then put the container into boiling water and boil for 10 minutes to terminate the hydrolysis reaction; the obtained product is centrifuged, and the supernatant obtained by centrifugation is concentrated, dried under vacuum freezing (vacuum degree 40-44Pa) at -45°C-30°C, The angiotensin-converting enzyme inhibitory active peptide is obtained.

[0040...

Embodiment 2

[0041] Embodiment 2, a kind of production method of angiotensin-converting enzyme inhibitory active peptide, carry out the following steps successively:

[0042] 1), after mixing rice grains and distilled water in the container according to the weight ratio of 1:4, adjust the pH value to 7.9 with a sodium hydroxide solution with a concentration of 2.0M;

[0043] 2), after adding trypsin into the container, put it into a constant temperature water bath for enzymolysis reaction; the temperature of the water bath is 35°C, the reaction time is 4.5 hours, and the amount of trypsin is 1.6% of the weight of rice grains;

[0044] 3), then put the container into boiling water and boil for 12 minutes to terminate the hydrolysis reaction; the obtained product is centrifuged, and the supernatant obtained by centrifugation is concentrated, dried under vacuum freezing (vacuum degree 40-44Pa) at -45°C-30°C, The angiotensin-converting enzyme inhibitory active peptide is obtained.

[0045] Th...

Embodiment 3

[0046] Embodiment 3, a kind of production method of angiotensin-converting enzyme inhibitory active peptide, carry out the following steps sequentially:

[0047] 1), after mixing rice grains and distilled water in the container according to the weight ratio of 1:4.5, adjust the pH value to 8.1 with a sodium hydroxide solution with a concentration of 3.0M;

[0048] 2), after adding trypsin into the container, put it into a constant temperature water bath to carry out the enzymolysis reaction; the temperature of the water bath is 40°C, the reaction time is 3.5 hours, and the amount of trypsin is 1.4% of the weight of rice grains;

[0049] 3), and then put the container into boiling water and boil for 8 minutes to terminate the hydrolysis reaction; the obtained product is centrifuged, and the supernatant obtained by centrifugation is concentrated, dried under vacuum freezing (vacuum degree 40-44Pa) at -45°C-30°C, The angiotensin-converting enzyme inhibitory active peptide is obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com