Method and system for monitoring continuous exhaust of smoke

A monitoring system and flue gas emission technology, which are applied in measurement devices, color/spectral characteristic measurement, and analysis using electron paramagnetic resonance, etc., can solve the problem of increased failure probability, increased maintenance workload, and large maintenance workload and other problems, to achieve the effect of reducing the measurement delay time, saving the heat tracing pipeline, and reducing the maintenance workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

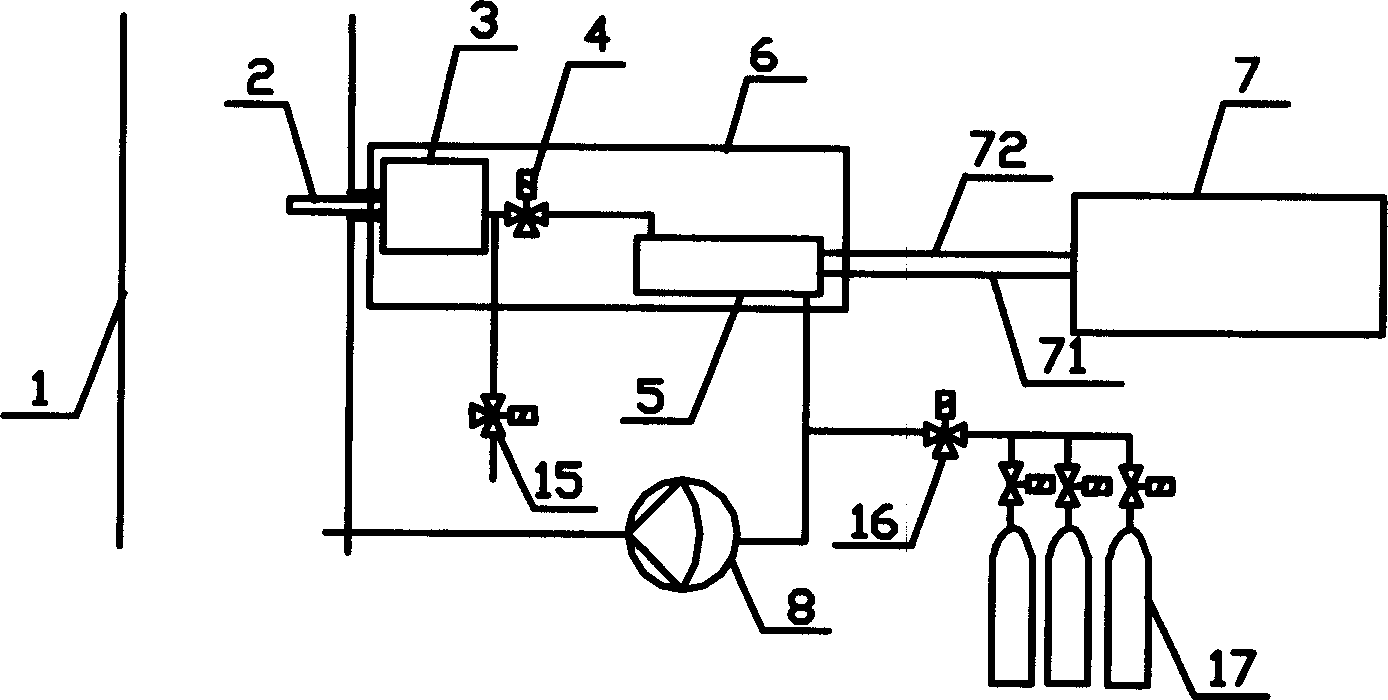

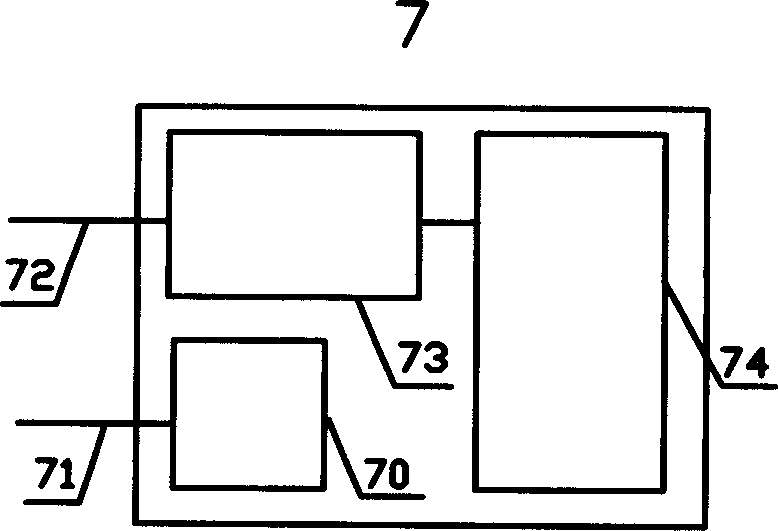

[0025] like figure 1 , image 3 As shown, a continuous monitoring system for flue gas emission includes a sampling probe 2, a heating device 6, a first measuring device, an air extraction pump 8, a standard gas cylinder 17 and valves 4, 15, 16. The sampling probe 2 is installed on the measured pipeline 1 and connected with the heating device 6 . The heating device 6 is equipped with a pretreatment device 3 such as a filter, a valve 4 and a measuring pool 5, and the preprocessing device 3 is connected to the valve 4 and the measuring pool 5 in sequence. An electric heating plate (not shown) is installed on the outer edge of the heating device 6, so that the pretreatment device 3 and the measuring cell 5 are heated together, so that the gaseous components in the heated measuring cell 5 are very close to the components in the measured pipeline 1 . The valve 15 is installed on the gas pipe behind the pretreatment device 3 , and the valve 16 and the standard gas bottle 17 are in...

no. 2 example

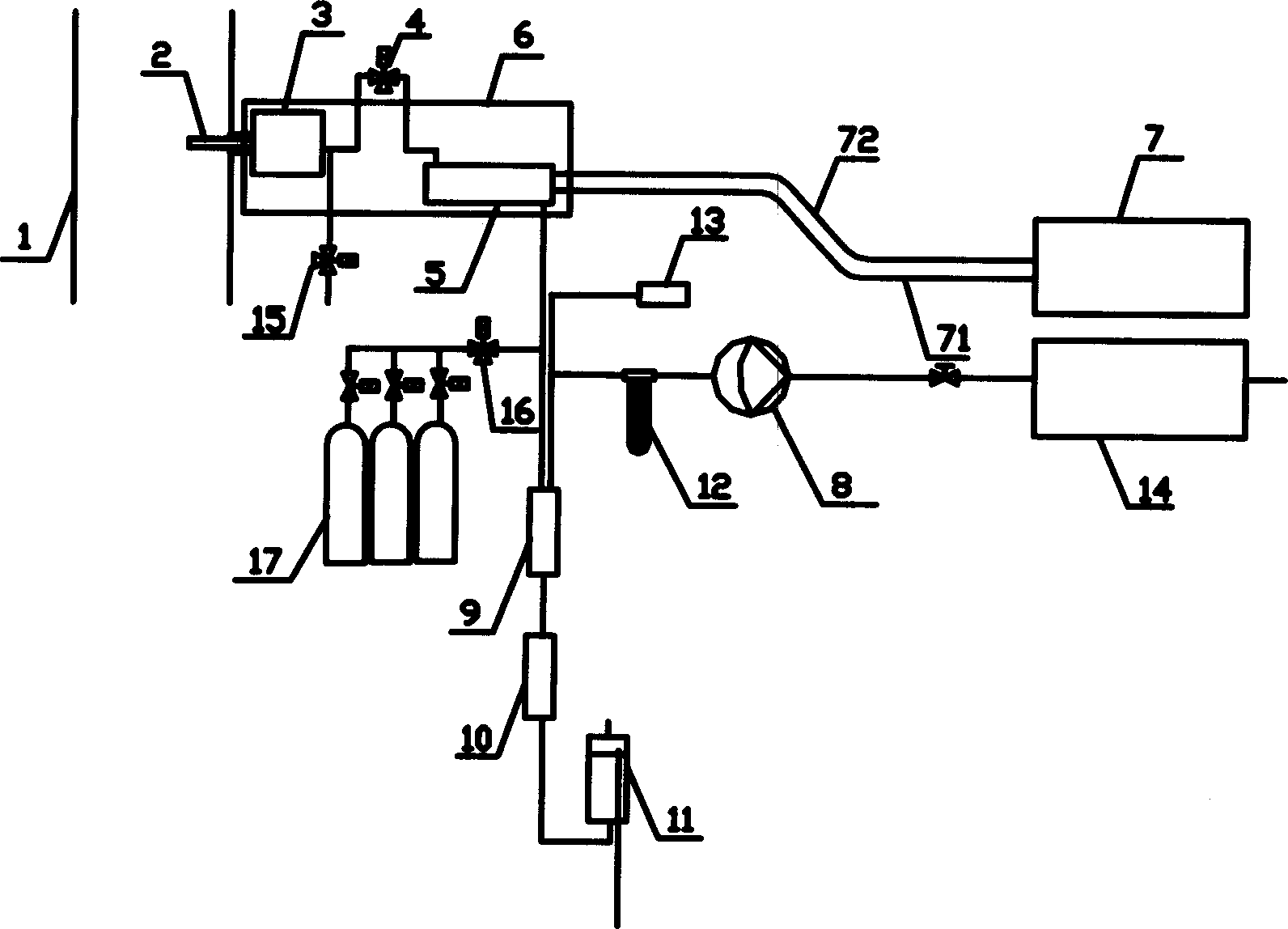

[0031] like figure 2 , Figure 4 As shown, a continuous monitoring system for flue gas emission is different from the first embodiment in that no humidity sensor and pressure sensor are installed on the heating measuring pool 5 . Heating plates are no longer installed on the outer edge of the heating device 6, but heating elements (not shown) are respectively installed on the outer edges of the pretreatment device 3 and the measurement pool 5, so that the pretreatment device 3 and the measurement pool 5 can be kept at different temperatures . The flue gas to be measured is discharged from the pretreatment device 3, such as a filter, and passes through the air pipe to the heating measurement pool 5. A part of the air pipe is exposed outside the heating device 6, and a valve 4 is installed on the exposed part of the air pipe. The monitoring system also includes a water removal device, a second measuring device, and the heating measuring pool 5 is connected to the water remova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com