Bionic machine fish with shape memory alloy wire for swinging forward

A technology of memory alloy wire and wave propulsion, applied in the field of robots, can solve the problems of complex structure, high noise and high cost of robots, and achieve the effect of simple structure, good bionic effect and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0010] Embodiment 1: Shape memory alloy wire (SMA wire) is a kind of smart material, which exhibits a thermoelastic martensitic change, that is, they are flexible below a certain transition temperature, because they are in the martensitic state. Bulk phase, which can be easily deformed. When its temperature is raised above the transformation temperature, the material reverts to its austenitic phase and previous shape, and thus generates greater force. Similarly, when the shape memory alloy wire is in the martensitic phase, it can easily stretch along its axial direction and maintain the stretched state. When it is heated above the transformation temperature, it will return to the state before stretching along its axial direction, that is, shrinkage recovery. , and generate a larger force.

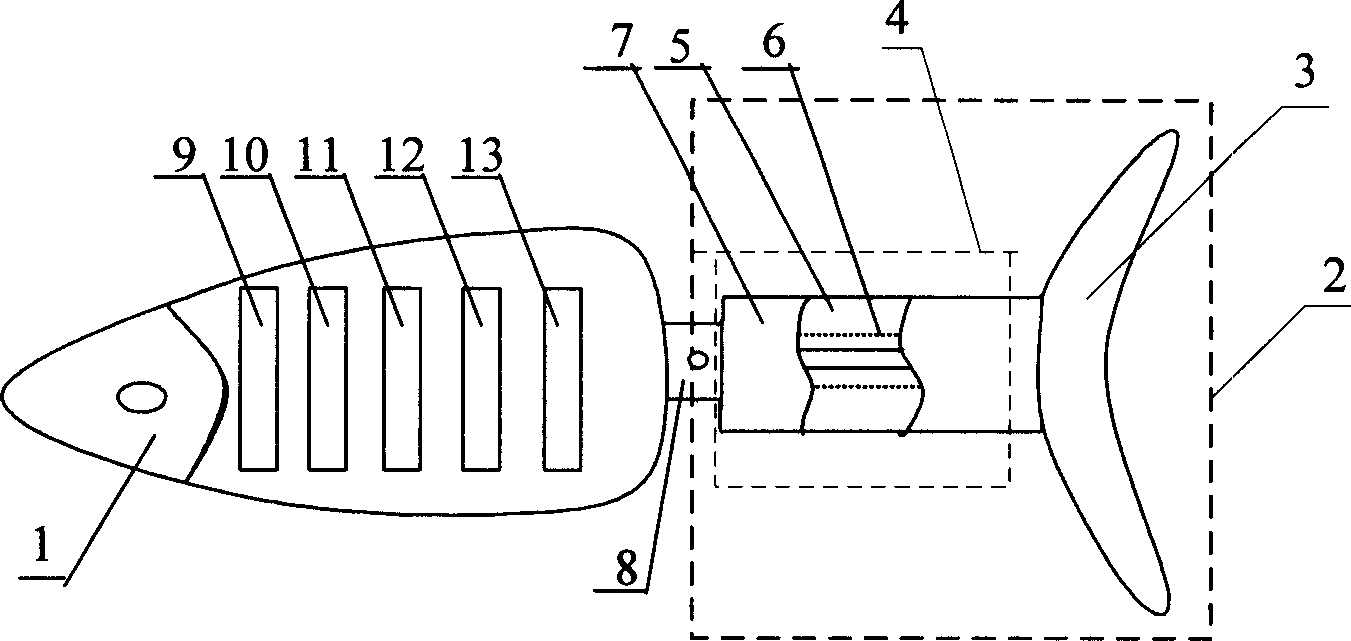

[0011] The present invention utilizes the contraction effect of the shape memory alloy wire to work, and the specific structure is as follows: the body wave driven by the shape memory allo...

specific Embodiment approach 2

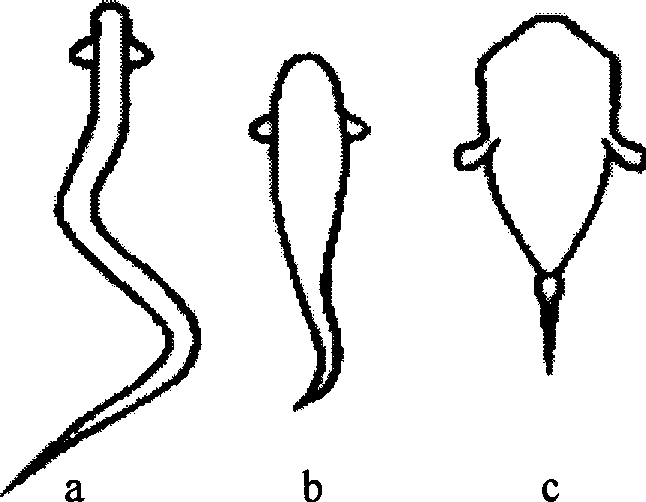

[0014] Specific implementation mode two: biologists simply classify the swimming patterns of fish according to the shape of the fish itself, the length of the caudal fin propulsion structure and the power of swing, which can be divided into three types (refer to figure 2 ):

[0015] a. Anguilliform: (eel-like) to swim by undulation of the muscles of the whole body, like an eel;

[0016] b. Carangiform: Swimming by swinging the caudal fin and the body connected to the tail, like salmon, tuna, sailfish;

[0017] c.Ostraciifrom: Swimming only by the swing of the caudal fin without body swing.

[0018] In actual use, various types of swimming modes can be simulated by changing the length ratio between the elastic piece 5 and the rigid fish head 1 and by increasing or decreasing the number of swing joints of the elastic piece. The bionic fish described in this embodiment refers to bionic Anguilliform swimming, that is, a smaller rigid fish head 1 and a longer caudal fin propulsi...

specific Embodiment approach 3

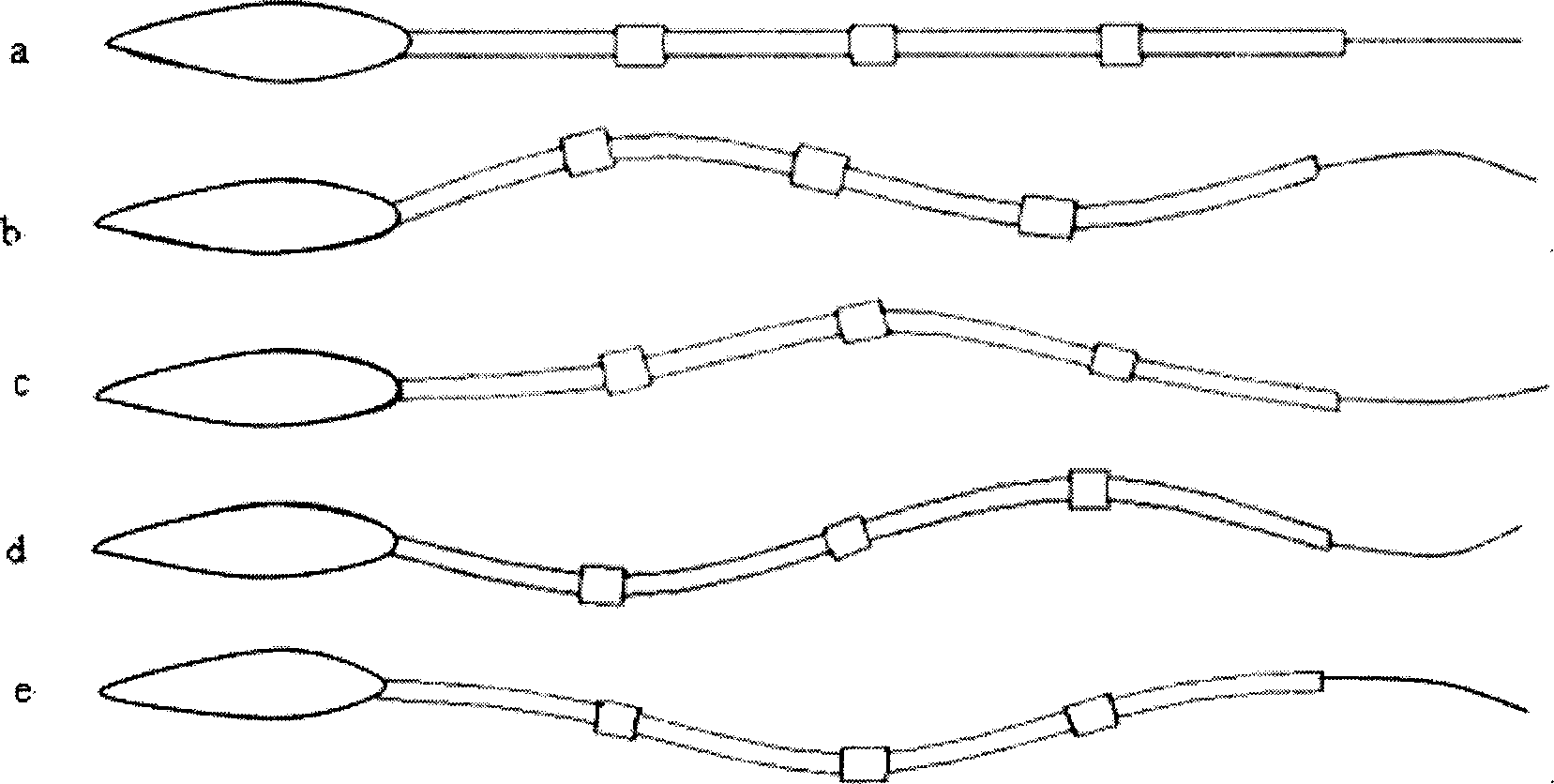

[0019] Specific embodiment three: This embodiment is a bionic Carangiform-style swimming robot fish with two swing joints. For specific structures, see Figure 4 , its propulsion method see Figure 5 The timing diagram of the joint swing action is shown, the previous joint is used for steering, and the latter joint is used for propulsion. Figure 5 The action state in the timing diagram shown: a is the initial state; b and c are a group, which is the swimming state when the bionic fish turns to the side; d and e are a group, which is the swimming state when the bionic fish turns to the side. dynamic state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com