Method for producing Nd2Fe14B/Fe double-phase nano crystal composite permanent-magnetic materials

A nanocrystalline composite, nd2fe14b technology, used in magnetic materials, inductor/transformer/magnet manufacturing, magnetic objects, etc., can solve problems such as uneven distribution, slow progress in bulk preparation, and poor contact between grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

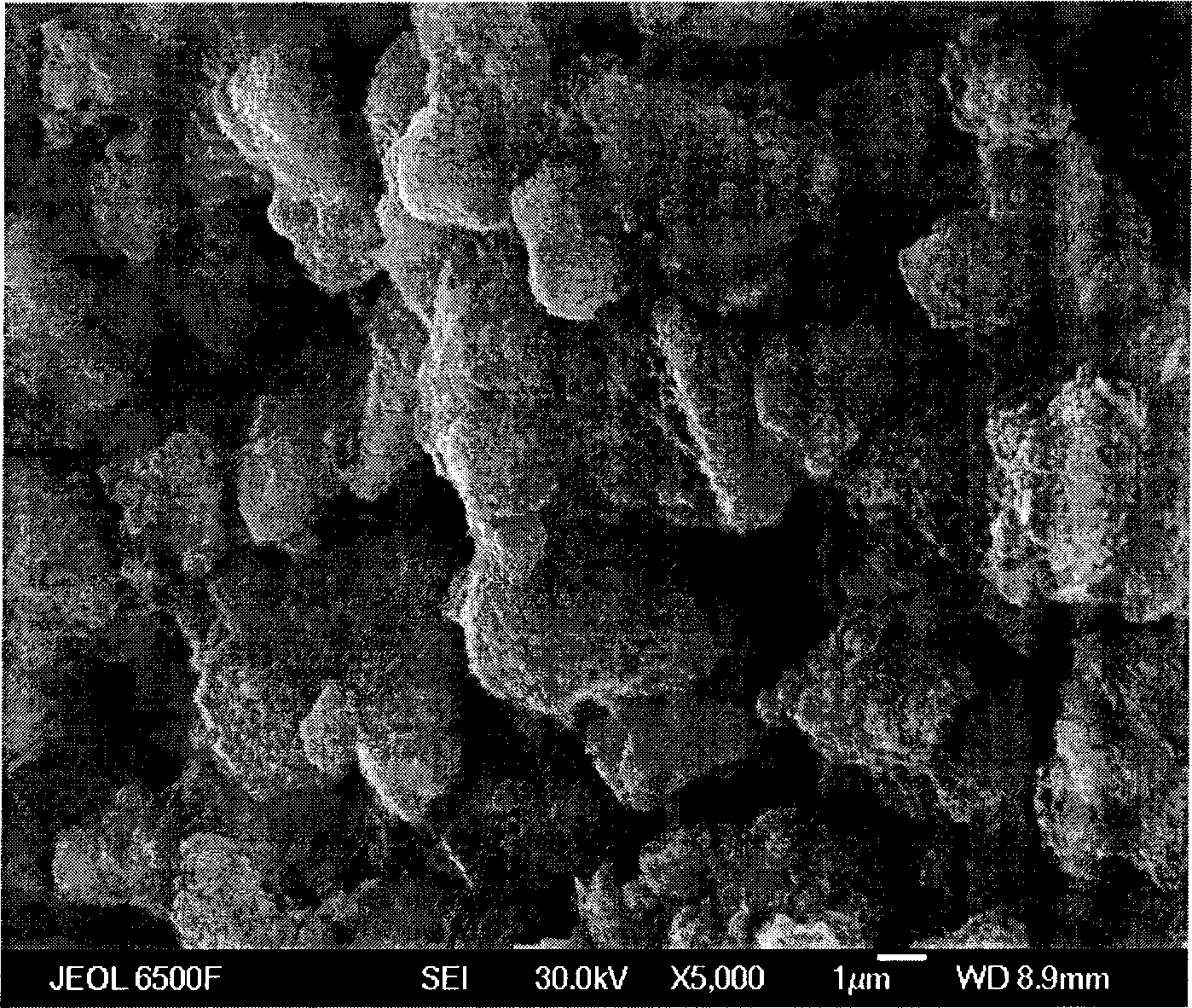

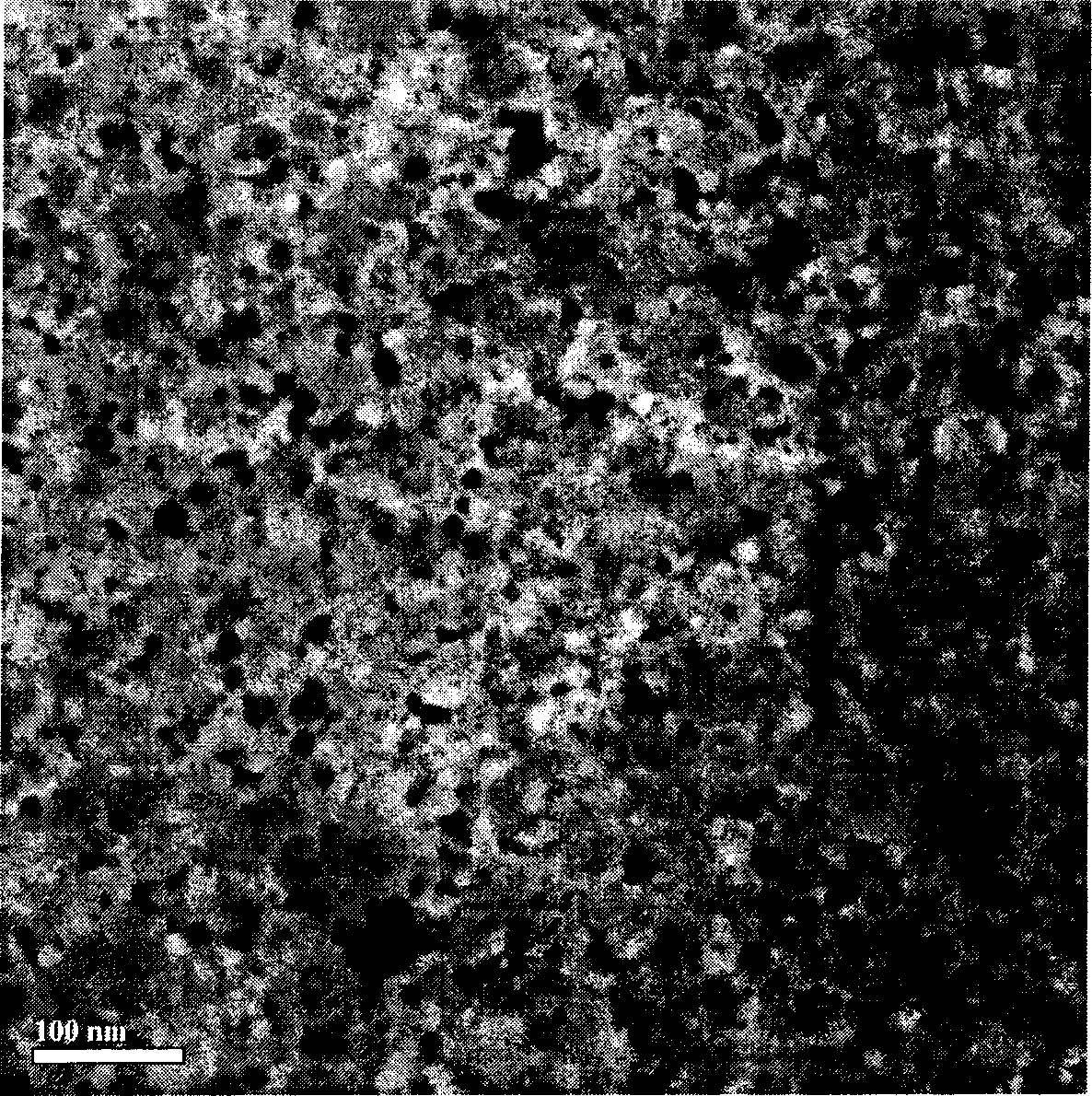

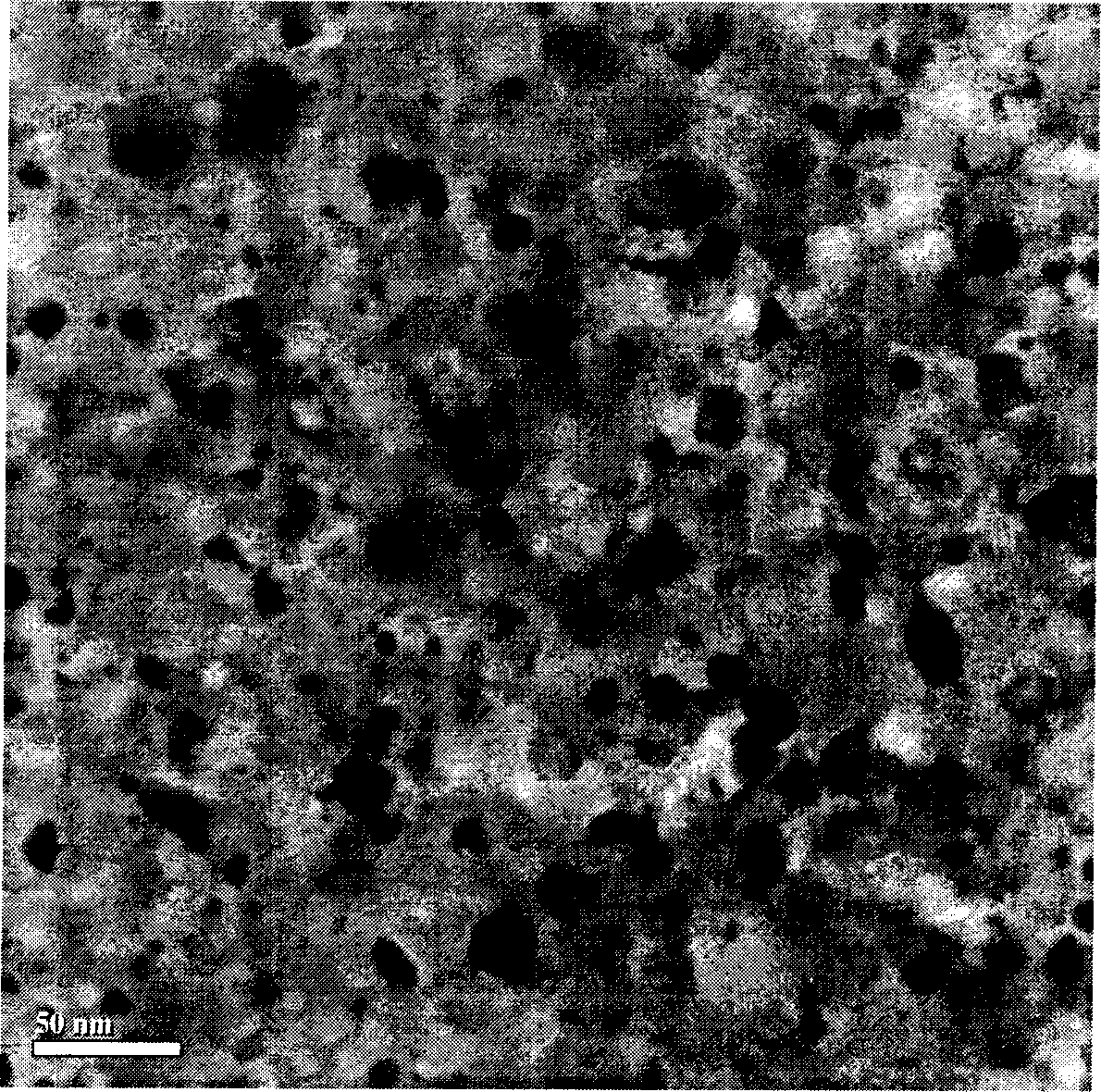

[0019] Inert N 2 Under the protection of gas, the ball milled to the Nd below 5μm 2 Fe 14 B hard magnetic powder is dispersed in liquid n-decane; Fe(CO) is added 5 Liquid, make Nd 2 Fe 14 B and Fe(CO) 5 The weight ratio of Fe in the medium is 9:1, then cool the temperature of the solid-liquid mixture to below 0°C, and then cool the temperature of the solid-liquid mixture to below 0°C; insert the ultrasonic head into the above-mentioned solid-liquid mixture, and turn on Ultrasonic generator, the power is adjusted to 100W, and the reaction time is 3 hours; after the reaction, centrifuge to remove the liquid, wash the solid product with n-pentane several times, and obtain the coated Nd after volatilization of n-pentane 2 Fe 14 B / Fe nanocomposite magnetic powder, such as figure 1 As shown, after sonochemical coating, Nd 2 Fe 14 The surface of the B particle is covered with a layer of extremely fine Fe particles, the size of which is less than 100nm; the material is loaded...

Embodiment 2

[0021] Under the protection of inert Ar gas, ball mill to the Nd below 5μm 2 Fe 14 B hard magnetic powder is dispersed in liquid n-decane; Fe(CO) is added 5 Liquid, make Nd 2 Fe 14 B and Fe(CO) 5 The weight ratio of Fe in the medium is 9:1, then cool the temperature of the solid-liquid mixture to below 0°C, and then cool the temperature of the solid-liquid mixture to below 0°C; insert the ultrasonic head into the above-mentioned solid-liquid mixture, and turn on Ultrasonic generator, the power is adjusted to 150W, and the reaction time is 2 hours; after the reaction, centrifuge to remove the liquid, wash the solid product with n-pentane several times, and obtain the coated Nd after volatilization of n-pentane 2 Fe 14 B / Fe nanocomposite magnetic powder; put the material into a cemented carbide mold, place it in a spark plasma sintering furnace, pre-fix the pressure at 500MPa, and heat it up to 630°C at a rate of 70°C / min in an Ar gas environment for sintering. The sinteri...

Embodiment 3

[0023] Inert N 2 , under the protection of Ar mixed gas, ball milled to the Nd below 5μm 2 Fe 14 B hard magnetic powder is dispersed in liquid n-decane; Fe(CO) is added 5 Liquid, make Nd 2 Fe 14 B and Fe(CO) 5 The weight ratio of Fe in the medium is 9:1, then cool the temperature of the solid-liquid mixture to below 0°C, and then cool the temperature of the solid-liquid mixture to below 0°C; insert the ultrasonic head into the above-mentioned solid-liquid mixture, and turn on Ultrasonic generator, the power is adjusted to 240W, and the reaction time is 3 hours; after the reaction, centrifuge to remove the liquid, wash the solid product with n-pentane several times, and obtain the coated Nd after volatilization of n-pentane 2 Fe 14 B / Fe nanocomposite magnetic powder; put the material into a cemented carbide mold, place it in a spark plasma sintering (SPS) furnace, pre-fix the pressure at 1000MPa, and heat up to 700°C at a rate of 100°C / min in an Ar gas environment Carry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com