High-formability magnesium alloy double-layer composite plate containing rare earth yttrium and preparation method of high-formability magnesium alloy double-layer composite plate

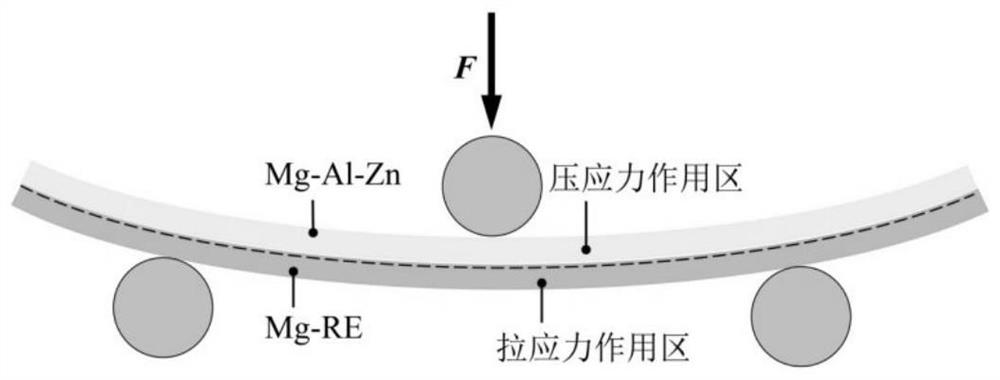

A magnesium alloy sheet and magnesium alloy technology are applied in the field of high formability magnesium alloy double-layer composite sheet and its preparation, which can solve problems such as cracking and failure, and achieve the effects of good bonding performance, fine grain structure and improved formability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A magnesium alloy ingot (Mg-0.2wt%Y) with a low content of rare earth yttrium is prepared according to the designed alloy composition ratio, and the magnesium ingot and the Mg-30wt%Y master alloy are used as raw materials; under the protective gas, the magnesium ingot is added Heat and melt in a melting furnace, raise the temperature to 720°C, add Mg-Y master alloy to the magnesium liquid, heat up to 740°C after melting, keep the temperature for 15 minutes, let stand and cool to 720°C for casting, and obtain Mg-0.2 wt% Y alloy ingot billet.

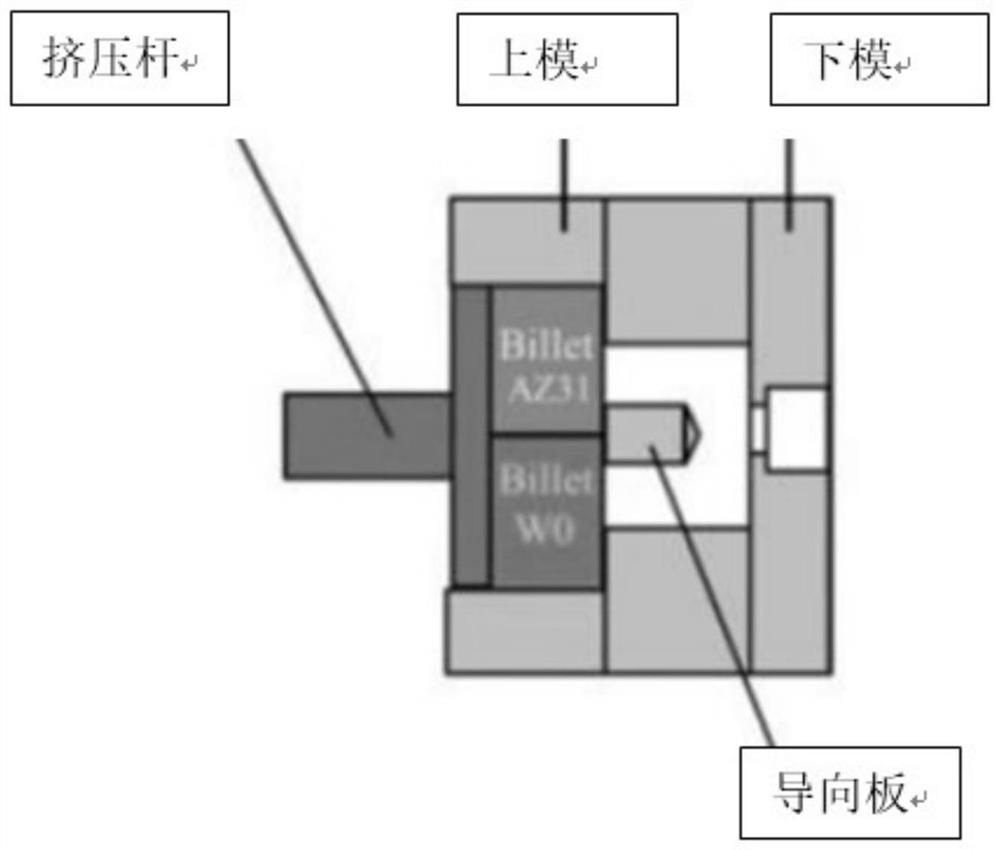

[0036] The smelted Mg-0.2wt% Y alloy and the AZ31 ingot were cut into two semi-cylindrical bodies with the same volume along the axial direction by wire-cutting the round ingot with a diameter of 80 mm and a height of 80 mm. Then the semi-cylindrical AZ31 and Mg-0.2wt%Y ingots were spliced into a complete cylinder. Homogenization treatment at 400°C for 12h before extrusion. Then carry out symmetrical split die extrusion at 380°...

Embodiment 2

[0049] A magnesium alloy ingot (Mg-0.2wt%Y) with a low content of rare earth yttrium (Mg-0.2wt%Y) is equipped with a magnesium ingot and a Mg-Y master alloy as raw materials according to the designed alloy composition ratio; under a protective gas, the magnesium ingot is added to the smelting furnace Heat and melt in medium temperature, raise the temperature to 720°C, add Mg-Y master alloy to the magnesium liquid, heat up to 740°C after melting, keep warm for 15 minutes after uniform temperature, stand and cool to 720°C for casting, and obtain Mg-0.2wt% Y alloy ingot billet.

[0050] The smelted Mg-0.2wt% Y alloy and the AZ31 ingot were cut into two semi-cylindrical bodies with the same volume along the axial direction by wire-cutting the round ingot with a diameter of 80 mm and a height of 80 mm. Then the semi-cylindrical AZ31 and Mg-0.2wt%Y alloys were spliced into complete cylinders. Homogenization treatment at 400°C for 12h before extrusion. Then carry out symmetrical ...

Embodiment 3

[0056] A magnesium alloy ingot (Mg-0.3wt%Y) with a low content of rare earth yttrium (Mg-0.3wt%Y) is equipped with a magnesium ingot and a Mg-Y master alloy as raw materials according to the designed alloy composition ratio; under a protective gas, the magnesium ingot is added to the smelting furnace Heat and melt in medium temperature, raise the temperature to 720°C, add Mg-Y master alloy to the magnesium liquid, heat up to 740°C after melting, keep warm for 15 minutes after uniform temperature, stand and cool to 720°C for casting, and obtain Mg-0.5wt% Y alloy ingot billet.

[0057] The smelted Mg-0.3wt% Y alloy and the AZ31 ingot were cut into two semi-cylindrical bodies with the same volume along the axial direction by wire-cutting the round ingot with a diameter of 80 mm and a height of 80 mm. Then the semi-cylindrical AZ31 and Mg-0.3wt%Y alloys were spliced into complete cylinders. Homogenization treatment at 400°C for 12h before extrusion. Then carry out symmetrical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com