Methods for the preparation of a fine chemical by fermentation

A chemical and sophisticated technology that can be used in fermentation, medical preparations containing active ingredients, pharmaceutical formulations, etc., and can solve problems such as consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

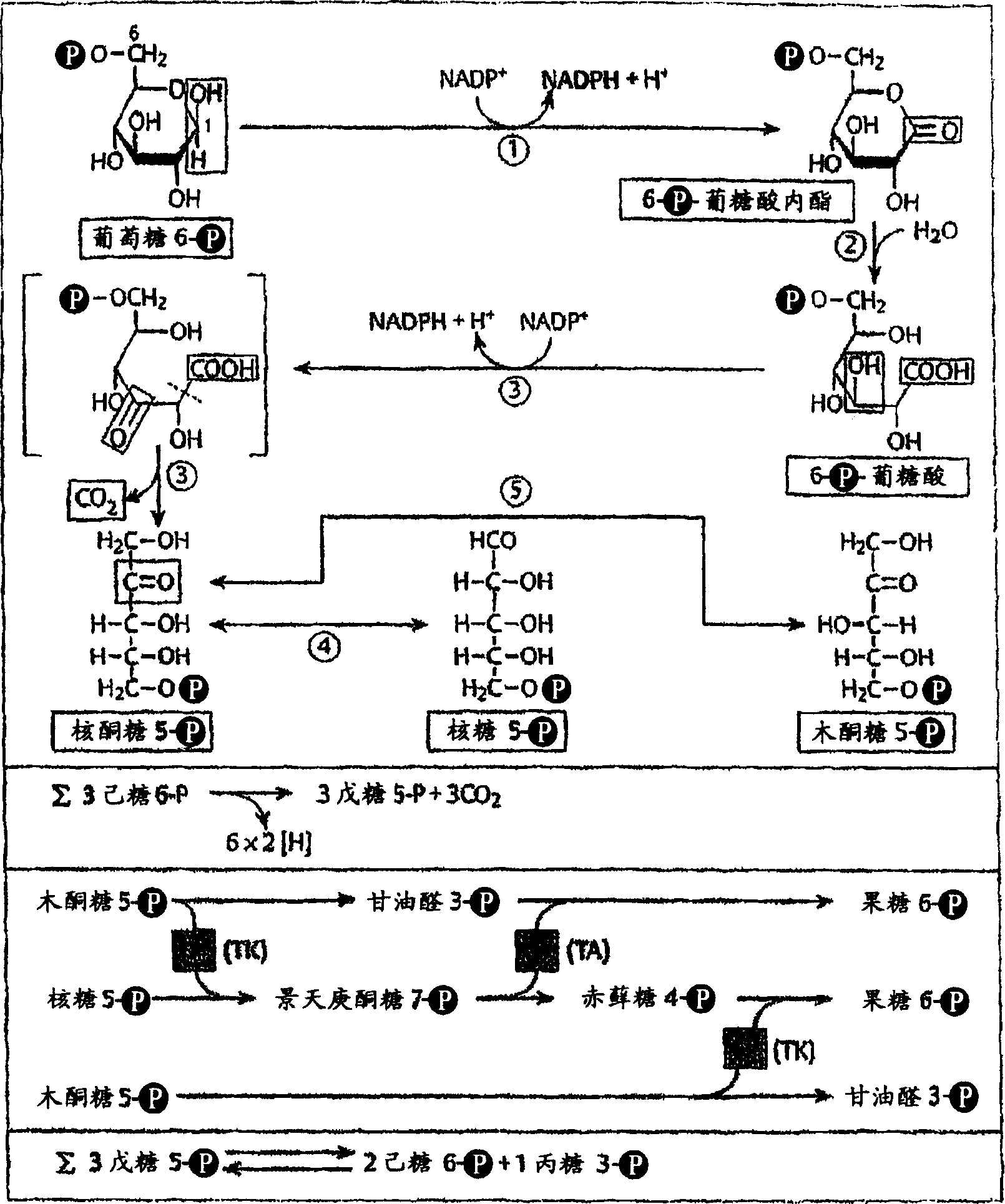

Method used

Image

Examples

Embodiment 1

[0169] Example 1: Production of lysine from fructose and glucose by Corynebacterium glutamicum

[0170] Analysis of the metabolic flux of lysine-producing Corynebacterium glutamicum in comparative batch cultures with glucose and fructose. For this, pre-grown cells were transferred to tracking medium and incubated for approximately 5 hours. Analysis of substrates and products at the beginning and end of the chase experiment revealed significant differences between the two carbon sources. A total of 11.1 mM lysine was produced with glucose, while a lower concentration of only 8.6 mM was achieved with fructose. During the incubation period of more than 5 hours, the cell concentration changed from 3.9g L -1 Increased to 6.0g L -1 (glucose) and from 3.5g L -1 increased to 4.4g L -1 (fructose). Due to the fact that threonine and methionine are not present in the medium, internal sources are likely used by the cells for biomass synthesis. The average specific sugar absorption ...

Embodiment 2

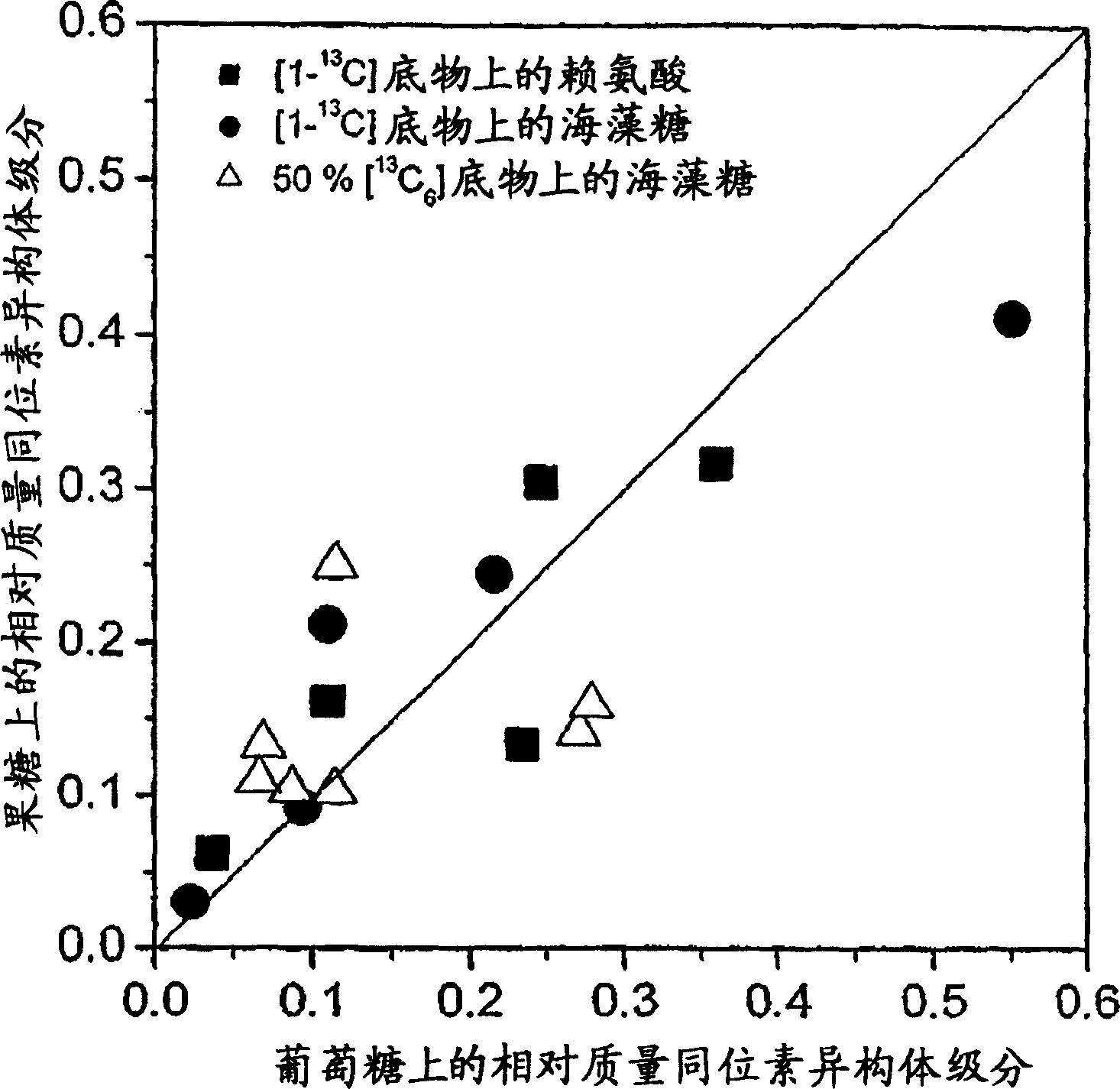

[0175] Example 2: In manual inspection and tracking experiments 13 C-marker type

[0176] The relative mass isotopomer fractions of secreted lysine and trehalose were quantified by GC-MS. These mass isotopomer fractions are sensitive to intracellular fluxes and thus show a fingerprint of the fluxome of the biological system under study. Such as figure 2 As shown in , the marker profile of secreted lysine and trehalose differs significantly between glucose- and fructose-grown cells of C. glutamicum. Differences were found for both the tracking markers applied and the products of the two measurements. This suggests substantial differences in carbon flux patterns depending on the carbon source applied. As previously shown, from Corynebacterium glutamicum to [1- 13 C] and [ 13 C 6 ] The mass isotopologue fractions of two parallel cultures of a glucose mixture were almost identical (Wittmann, C., H.M. Kim and E. Heinzle. 2003. Metabolicflux analysis at miniaturized scale. s...

Embodiment 3

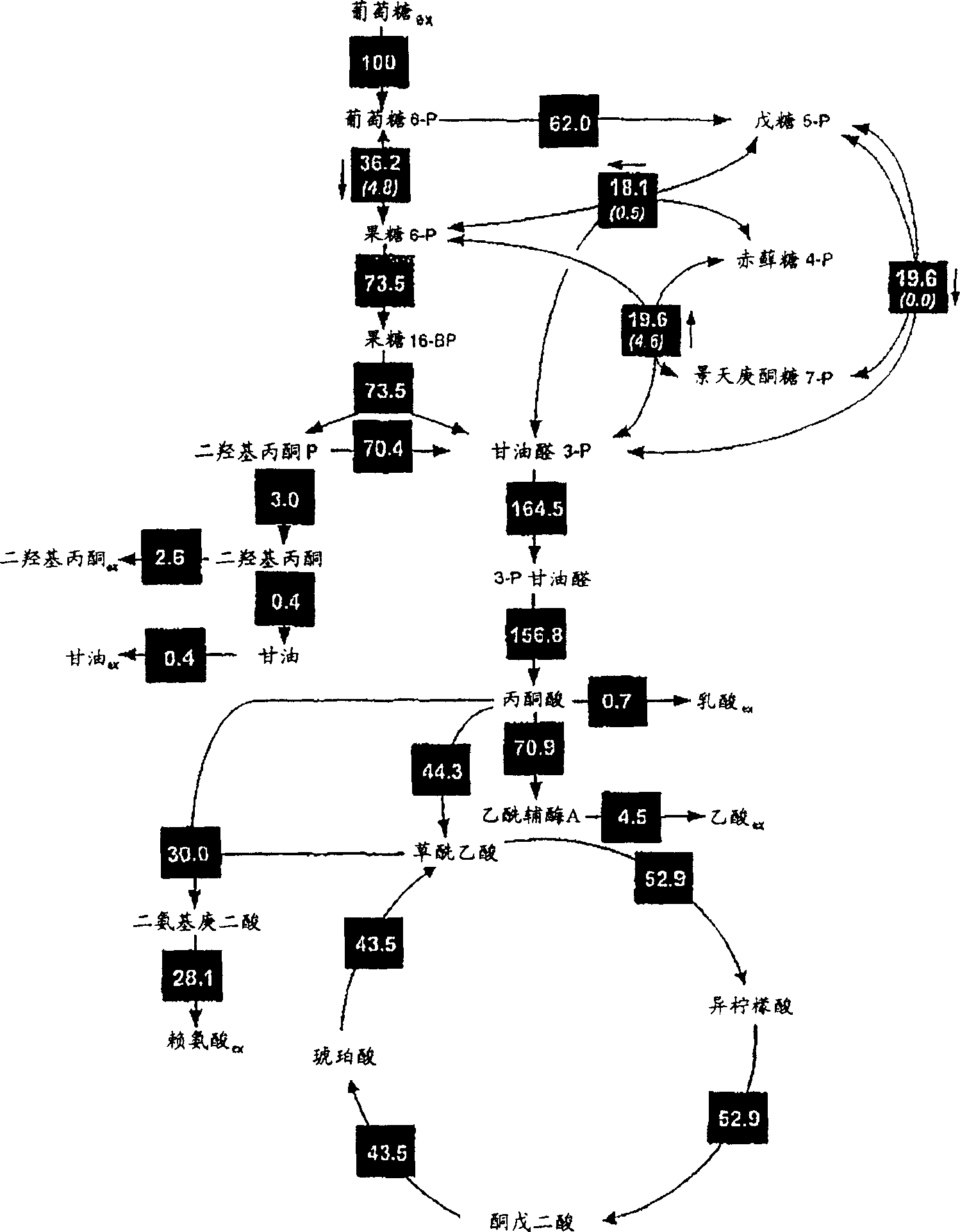

[0177] Example 3: Estimation of Intracellular Flux

[0178] The central question of the studies carried out was the comparative study of the intracellular flux of C. glutamicum during the production of lysine using glucose and fructose as carbon sources, respectively. To this end, the experimental data obtained from the tracking experiments were used to calculate the metabolic flux distribution for each substrate, using flux estimation software as described above. Parameter estimation was performed by minimizing the deviation between experimental and theoretical mass isotopomer fractions. The method performed utilizes an optimized metabolite balance during each step. This included (i) stoichiometric data on product secretion (Table 2) and (ii) stoichiometric data on anabolic requirements for biomass precursors (Table 3). The set of intracellular fluxes that gave the smallest deviation between experimental and simulated marker configurations was considered to be the best esti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com