Process for removing thermal barrier coatings

A thermal resistance, coating technology, applied in the direction of coating, metal material coating process, sustainable transportation, etc., can solve problems such as increased wear and erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

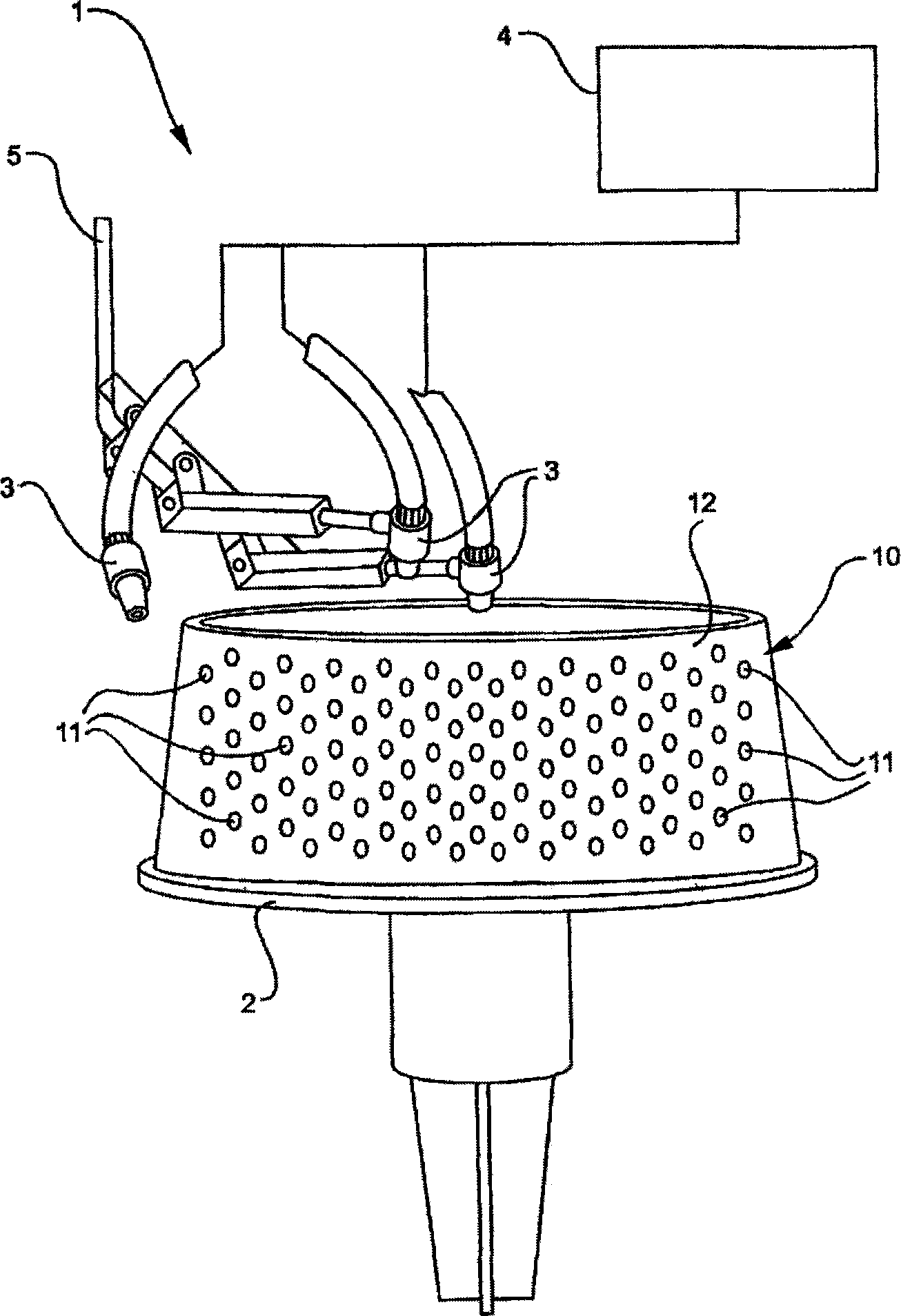

Image

Examples

example

[0019] The high temperature part of the jet engine combustion chamber (which is made of nickel or cobalt based superalloy material) is laser punched with air cooling holes during manufacture. The surface of this part of the gas passage (high temperature side) is first coated with a metal bonding layer, which is mainly nickel and contains chromium, aluminum and yttrium oxide (or another reactive element). The metal bonding layer is applied by a plasma spray process to a thickness, typically about 0.005 to 0.008 inches (about 0.13 to 0.020 mm). After the bonding layer is applied, the air cooling holes are laser drilled to generate the required angle of incidence to achieve the desired air cooling characteristics of the part. After laser drilling, the part is cleaned to remove laser slag, or waste material from the laser drilling process. After laser drilling and cleaning, a bond coat of approximately 0.001 to 0.003 inches thick can be applied by a plasma spray process, optional...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com