Marsh-gas dry fermenter with continuouslly and automatically feeding and discharging, its process and thermal-insulating and temperature-increasing method

A dry fermentation device, automatic technology, applied in the direction of waste fuel, gas production bioreactor, etc., can solve the problems of limitation, difficult discharge, difficult maintenance, etc., and achieve the effect of remarkable heat preservation effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

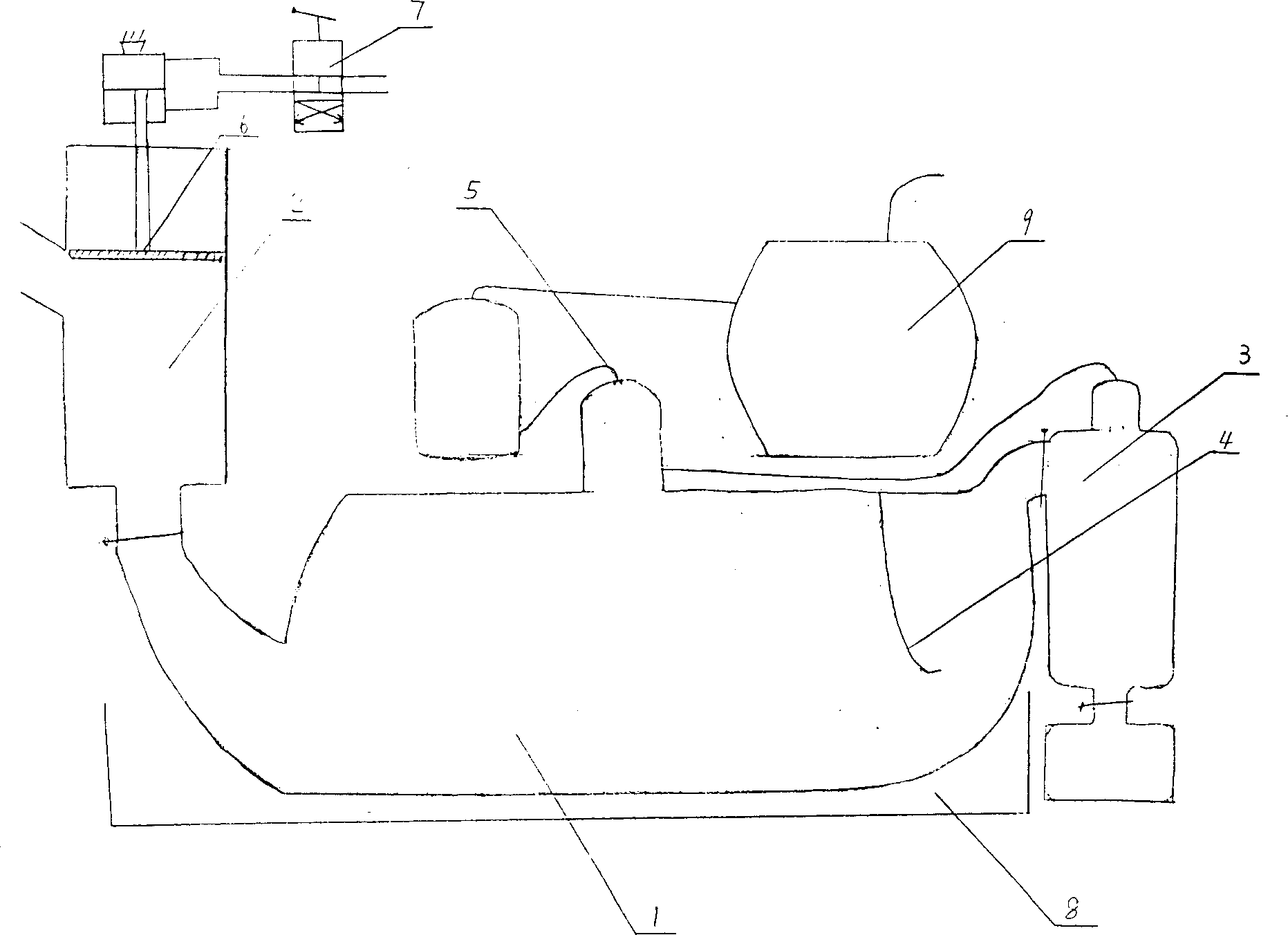

[0025] First, dig a deep pit on the ground. The length, width, and depth of the pit are 2 meters away from the periphery of the dry fermentation device as an isolation layer. The bottom of the dry fermentation device is placed on a base 0.5 meters from the bottom of the pit to cut off the influence of ground temperature on the dry fermentation device. ; The stone walls around the isolation layer and the bottom are buried with foam plastic boards at a depth of 1 meter, and the thickness of the boards is 10 cm, to further isolate the influence of ground temperature; Warm water bed, the diameter of the pipe is 20 cm, the length is 25 meters, and a total of 10 pipes are laid; the laid pipes are backfilled with sand or original soil as energy storage materials for solar energy; the backfilled sand and original soil are covered with heat preservation Materials; add multiple solar greenhouse heat collectors on the surface 1 meter away from the mouth of the pit.

Embodiment 2

[0027]First, dig a deep pit on the ground. The length, width, and depth of the pit are 3 meters away from the periphery of the dry fermentation device as an isolation layer. The bottom of the dry fermentation device is placed on a base 1 meter away from the bottom of the pit to cut off the influence of ground temperature on the dry fermentation device. ; The stone walls around the isolation layer and the bottom are buried with foam plastic boards at a depth of 1 meter, and the thickness of the boards is 10 cm to further isolate the influence of the ground temperature; Warm water bed, the diameter of the pipe is 30 cm, the length is 300 meters, 15 pipes are laid in total; sand and gravel or raw soil are backfilled on the laid pipes as energy storage materials for solar energy; Materials; add multiple solar greenhouse heat collectors on the surface 2 meters away from the mouth of the pit. In winter in the north, fill the thermal insulation material with yellow storage corn stalk...

Embodiment 3

[0029] First, dig a deep pit on the ground. The length, width, and depth of the pit are 2 meters away from the periphery of the dry fermentation device as an isolation layer. The bottom of the dry fermentation device is placed on a base 0.5 meters from the bottom of the pit to cut off the influence of ground temperature on the dry fermentation device. ; The stone walls around the isolation layer and the bottom are buried with foam plastic boards at a depth of 1 meter, and the thickness of the boards is 10 cm to further isolate the influence of the ground temperature; Warm water bed, the diameter of the pipeline is 25 cm, the length is 100 meters, and a total of 15 pipelines are laid; the laid pipelines are backfilled with sand or original soil as energy storage materials for solar energy; the backfilled sand and original soil are covered with heat preservation Materials; add multiple solar greenhouse heat collectors on the surface 1.5 meters outside the mouth of the pit. In wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com