Preparation method of nano-grade capsule material based on composite mould plate technology

A composite template, nano-scale technology, applied in the field of nano and polymer materials, can solve problems such as toxicity and complex process, and achieve the effects of reducing toxicity, excellent electrical insulation properties, and excellent physical and mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

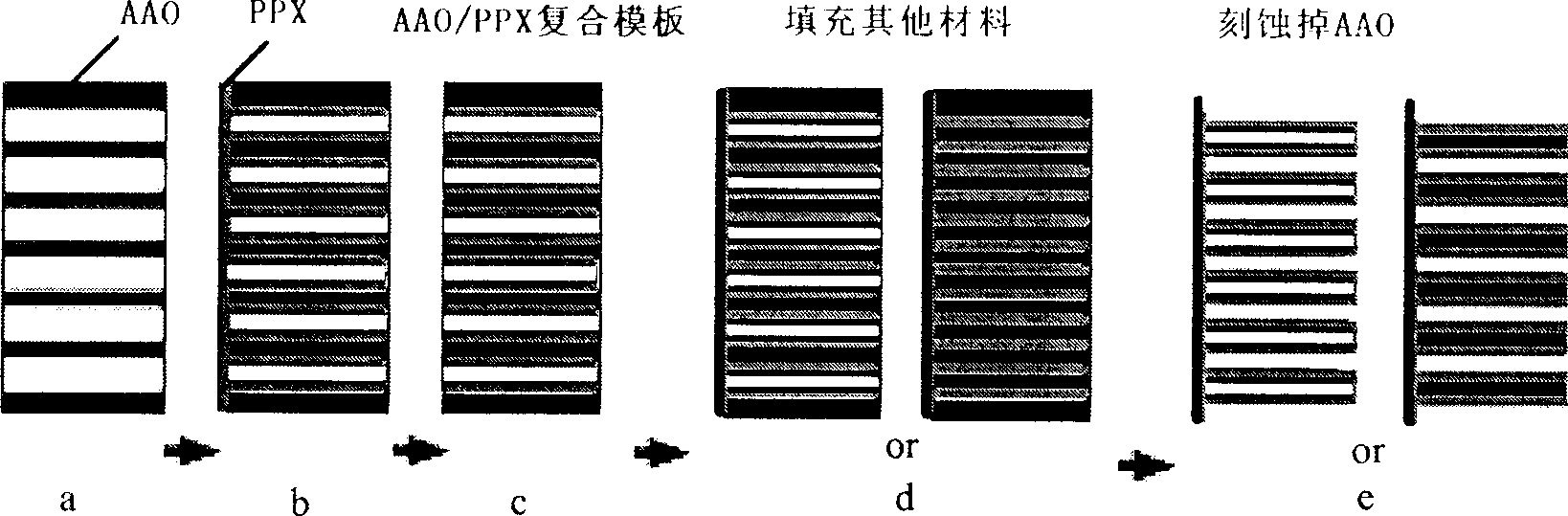

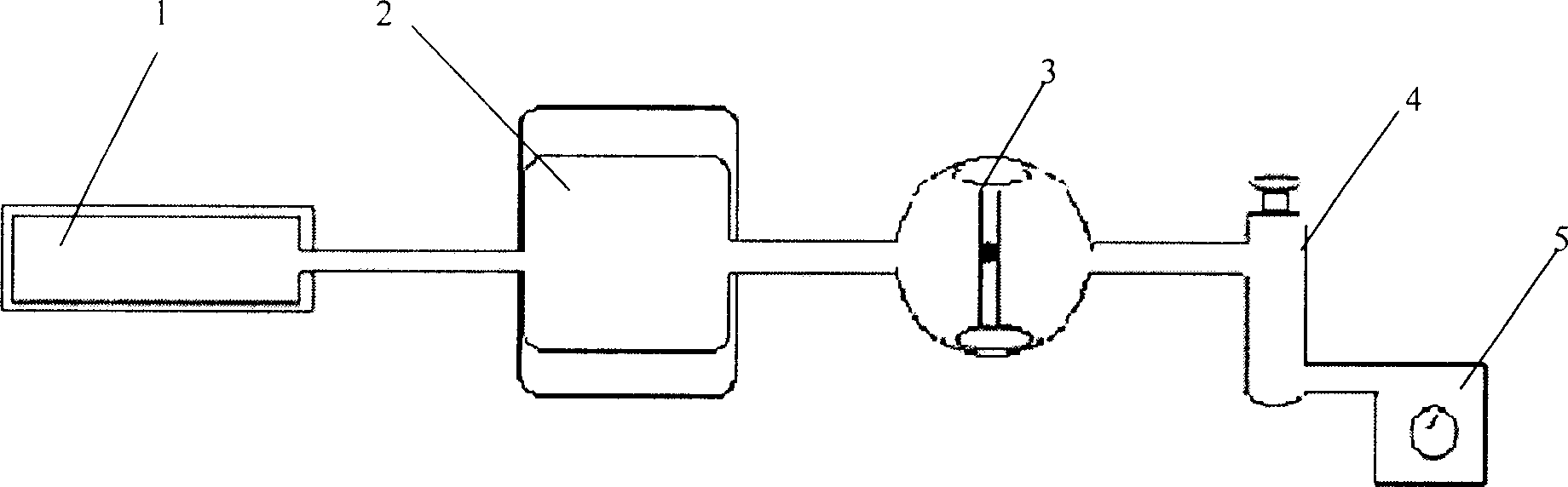

Method used

Image

Examples

Embodiment 1

[0034] The raw materials used in the embodiment are as follows:

[0035] Aluminum sheet (99.99%), Beijing Youyan Gold

[0036] p-Phenylene dimethylene dimer (type N, 99.0%), Fluka

[0037] Phosphoric acid, perchloric acid, Shanghai Jinlu Chemical Reagent Co., Ltd.

[0038] Disperse Red 1 (50%), Aldrich

[0039] (1) Preparation and characterization of AAO

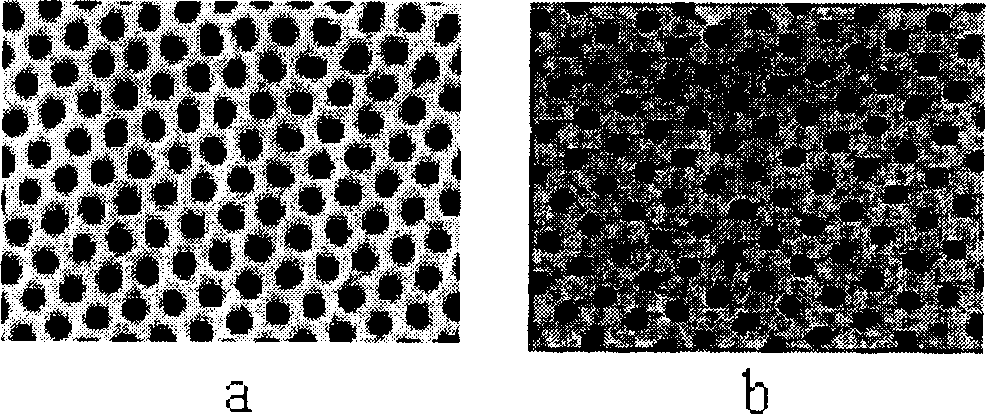

[0040] Preparation of AAO: 99.99% aluminum sheet is annealed at high temperature (500°C muffle furnace, 4-6 hours), degreased (sonication of aluminum chloride or acetone for 10-20 minutes, rinsed with distilled water), and aluminum oxide (10% NaOH, ultrasonic 10-20 minutes), electrolytic polishing (HCLO 4 : Absolute ethanol=1:4 volume ratio, 15V, electrolysis for 3-5 minutes) and then cleaned for later use. 30%H 3 PO 4 Anodize at 40V for 1-2 hours, and then oxidize again for 8-12 hours after removing the oxide layer. saturated HgCl 2 Dissolve the aluminum base, at 37 degrees H 3 PO 4 Expand the hole for 25-35 minu...

Embodiment 2

[0052] The raw materials used in the embodiment are as follows:

[0053] Aluminum sheet (99.99%), Beijing Youyan Gold

[0054] p-Phenylene dimethylene dimer (Type C, 99.0%), Fluka

[0055] Phosphoric acid, perchloric acid, Shanghai Jinlu Chemical Reagent Co., Ltd.

[0056] Disperse Red 1 (50%), Aldrich

[0057] (1) Preparation and characterization of AAO

[0058] Preparation of AAO: 99.99% of the aluminum sheet is annealed at high temperature (500°C in muffle furnace, 6-7 hours), degreased (sonication of aluminum chloride or acetone for 15 minutes, rinsed with distilled water), and de-alumina (10% NaOH, Ultrasonic for 15 minutes), electrolytic polishing (HCLO 4 : Absolute ethanol=1:4 volume ratio, 15V, electrolysis for 3 minutes) and then cleaned for later use. 30%H 3 PO 4 Anodize at 40V for 1.5 hours, and then oxidize again for 10 hours after removing the oxide layer. saturated HgCl 2 Dissolve the aluminum base, at 37 degrees H 3 PO 4 Ream the hole for 30 minutes, ...

Embodiment 3

[0070] The raw materials used in the embodiment are as follows:

[0071] Aluminum sheet (99.99%), Beijing Youyan Gold

[0072] p-Phenylene dimethylene dimer (Type D, 99.0%), Fluka

[0073] Phosphoric acid, perchloric acid, Shanghai Jinlu Chemical Reagent Co., Ltd.

[0074] Disperse Red 1 (50%), Aldrich

[0075] (1) Preparation and characterization of AAO

[0076] Preparation of AAO: 99.99% aluminum flakes are annealed at high temperature (500°C in muffle furnace, 5 hours), degreased (sonication of aluminum trichloride or acetone for 20 minutes, rinsed with distilled water), aluminum oxide removal (10% NaOH, ultrasonication for 10 minutes) minutes), electrolytic polishing (HCLO 4 : Absolute ethanol=1:4 volume ratio, 15V, electrolysis for 4 minutes) and then cleaned for later use. 30% of the hour H 3 PO 4 Anodize at 40V for 2 hours, and then oxidize again for 12 hours after removing the oxide layer. saturated HgCl 2 Dissolve the aluminum base, at 37 degrees H 3 PO 4 R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com