Method for making gallium arsenide/gallium stibide laminated focusing solar battery

A technology of solar cells and gallium arsenide, which is applied in the manufacture of circuits, electrical components, and final products. It can solve the problems of difficult space heat dissipation, complex day tracking mechanism, and high cost, and achieve low investment, high solar energy utilization, and long life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

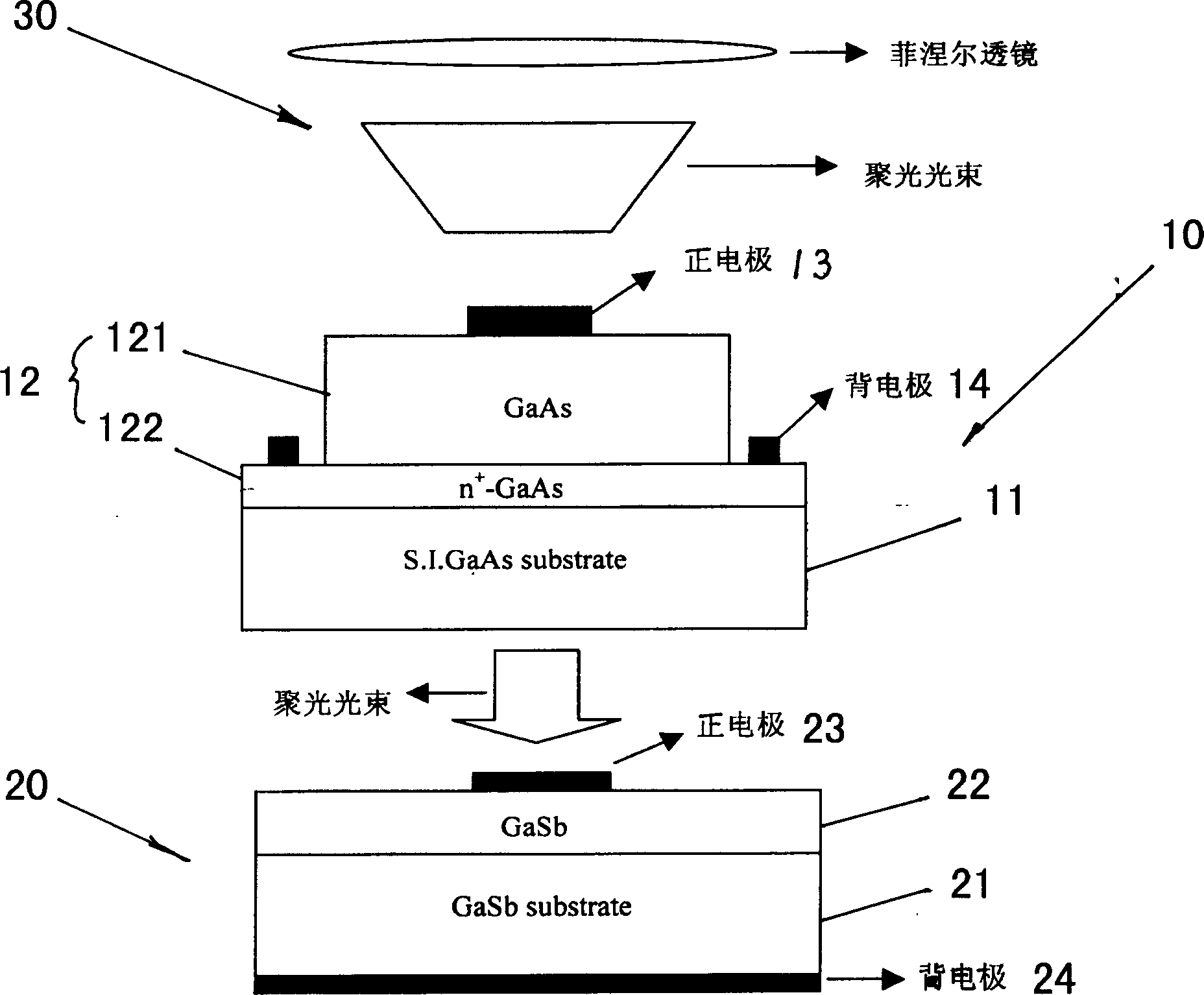

[0040] (1): The top cell is based on a semi-insulating gallium arsenide single wafer;

[0041] (2): Using metal organic compound vapor deposition (MOCVD), molecular beam epitaxy (MBE) and liquid phase epitaxy (LPE) growth techniques to grow solar cell epitaxial wafers. The bottom layer of epitaxial growth is heavily doped n + - GaAs layer;

[0042] (3): The positive electrode is made on the epitaxial wafer of the top cell; the n above the semi-insulating gallium arsenide (SI-GaAs) substrate + -GaAs layer to make the back electrode of the top cell;

[0043] (4): Make a positive electrode on the epitaxial wafer of the bottom cell, and make a back electrode under the substrate;

[0044] (5): The top cell and the bottom cell are mechanically cascaded to make a mechanical laminated solar cell;

[0045] (6): Welding, testing, assembly, packaging, and comprehensive testing of solar cell components after packaging;

[0046](7): Use a bracket to install a concentrating device and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com