Shell type needle roller bearing, support structure of compressor spindle, and support structure of piston pump drive part

A technology for needle roller bearings and compressors, applied in needle roller bearings, roller bearings, rolling contact bearings, etc., can solve the problems of heat treatment interruption and unqualified, and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

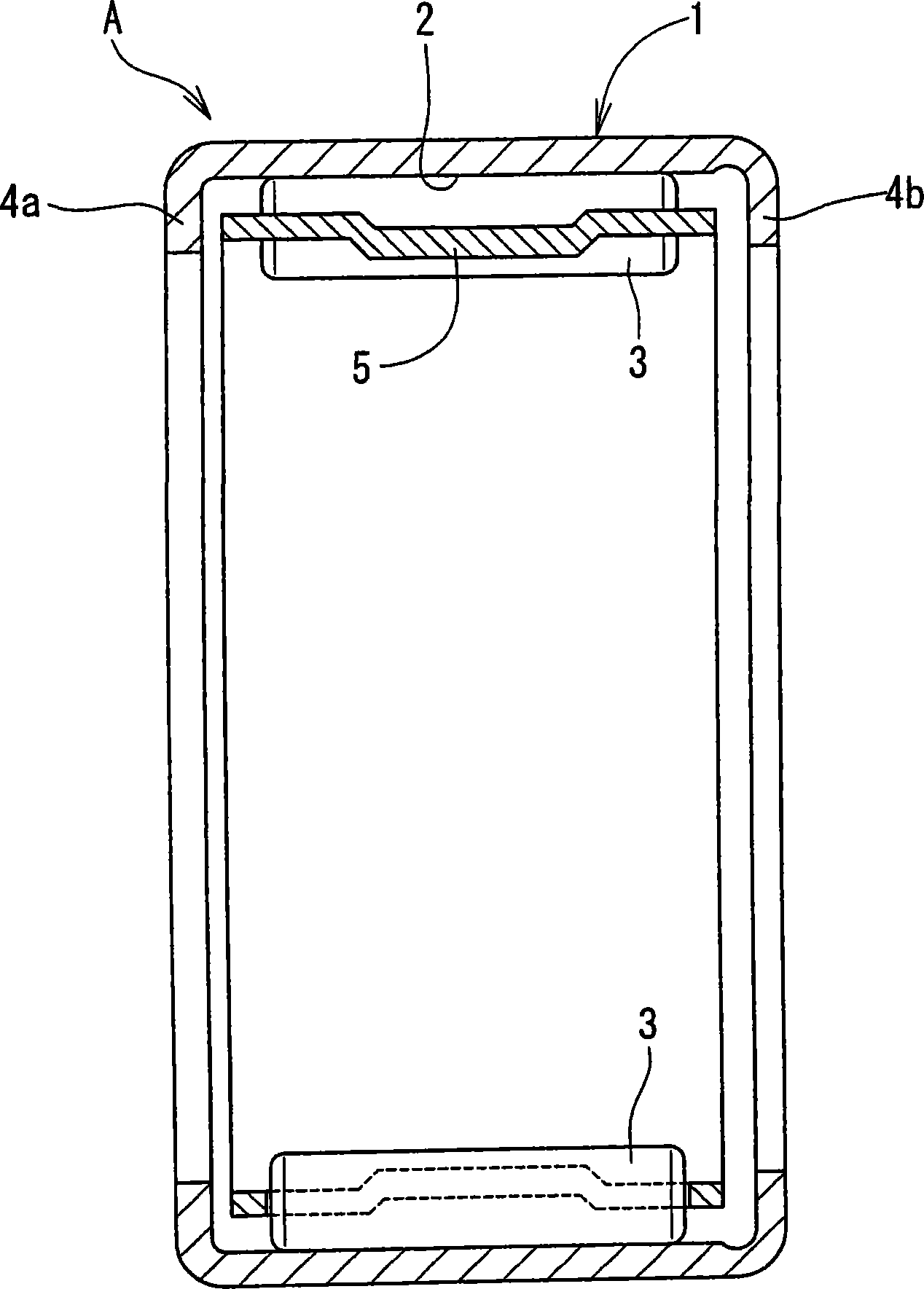

[0070] Hereinafter, embodiments of the present invention will be described based on the drawings. The shell type needle roller bearing A of the present invention, such as figure 1 As shown, a plurality of needle rollers 3 are arranged along the inner diameter surface 2 that is the raceway surface of the shell-shaped outer ring 1 formed by the press working of the steel plate. The outer ring 1 is of an open-end type, and flanges 4a and 4b are formed at both ends. In addition, the needle roller 3 is a retainer ring assembled to the retainer 5.

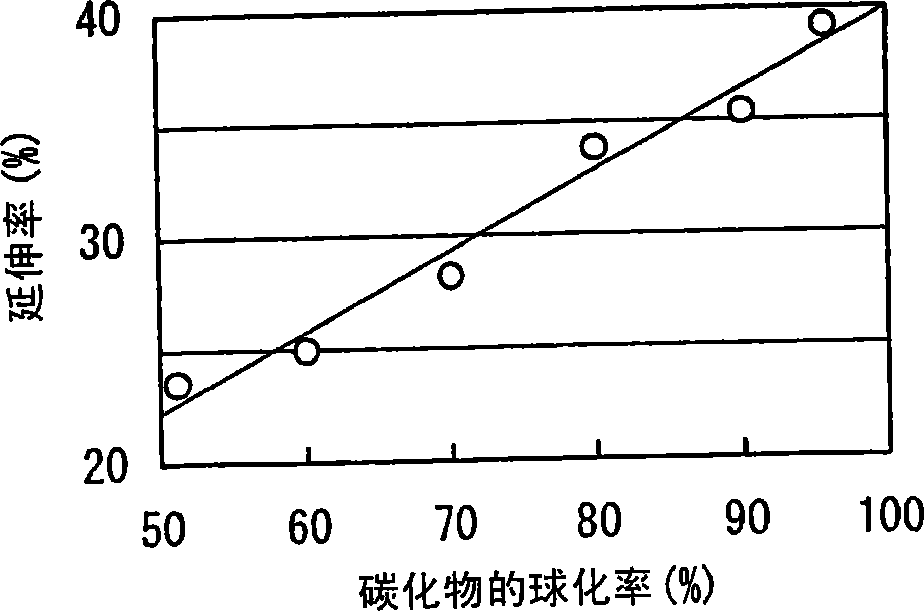

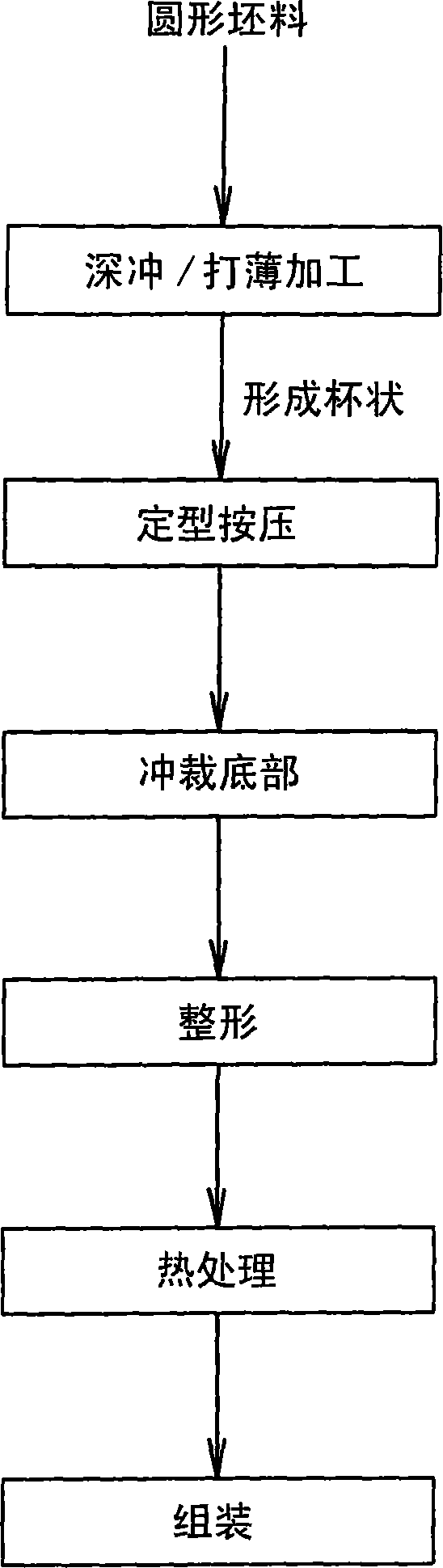

[0071]As the raw material for the steel plate forming the outer ring 1 in the press process, the following pairs were used: carbon structural steel S40C (Example 1) with a C content of 0.4% by mass; and a tool with a C content of 0.85% by mass Steel SK5 spheroidizing annealing is a steel with a spheroidization rate of 50% or more of carbides (Example 2); carbon structural steel S55C with a C content of 0.55 mass% and a Si content of 0.15 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| spheroidization ratio | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com