Process for preparing bean skin biosorption

A technology of biosorbent and adsorbent, which is applied in the field of preparation of soybean skin biosorbent, can solve the problems of restricting popularization and application, and achieve the effect of increasing adsorption capacity, high adsorption capacity and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Crush 10g of granular bean curd with particle size ≤ 3mm, add 300ml of 0.05M NaOH solution, mix and pretreat at 60°C for 2 hours, wash the particles with water until neutral. The granular bean curds were transferred into 20 ml of succinic acid solution for modification, the modification concentration was 0.5 M, the modification temperature was 130° C., and the modification was performed for 12 hours. Then move the bean curd to the aqueous solution to rinse until neutral. Dried at 60 °C to dry soybean hull biosorbent. Get 0.2g soybean hull biosorbent and 50ml Pb(NO 3 ) 2 Add the aqueous solution to a 150ml Erlenmeyer flask, and at room temperature, shake at a speed of 150dyn / m for 24 hours (adsorption equilibrium), and measure the metal ion Pb in the solution. 2+ The adsorption capacity is 89mg / g. The experimental results show that the adsorbent can be used in a wide range of pH = 2 to 11; desorb with 20ml of 0.5M hydrochloric acid for 0.5h, wash with water until neu...

Embodiment 2

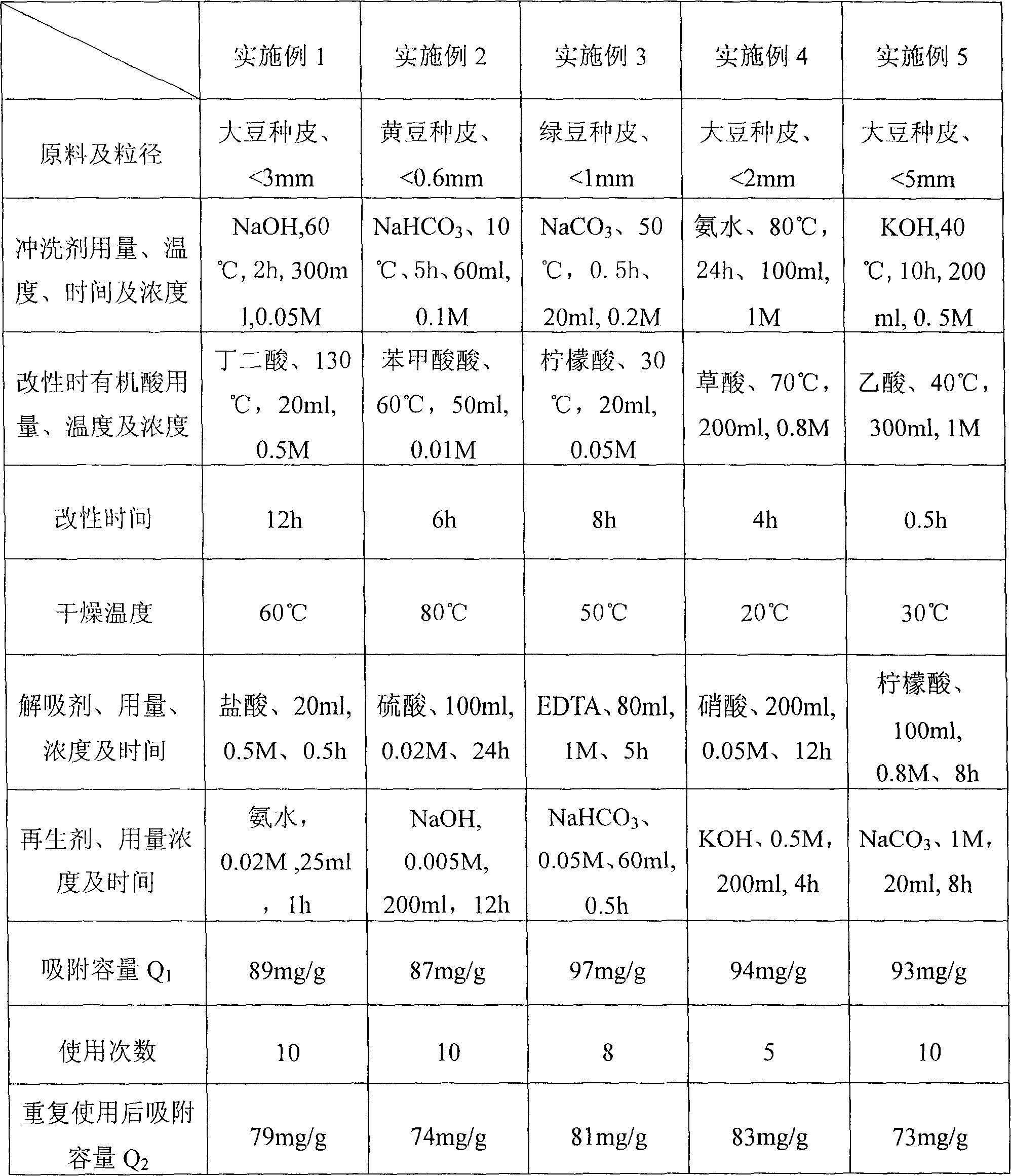

[0029] The operating methods of embodiment 2, embodiment 3, embodiment 4 and embodiment 5 are the same as embodiment 1, and the operating parameters are shown in table 1.

Embodiment 5

[0031] Crush 10g of granular bean curd with a particle size of ≤5mm, add 200ml of 0.5M KOH solution, mix and pretreat at 40°C for 10 hours, wash the particles with water until neutral. The granular bean curds were transferred into 300ml of acetic acid solution for modification, the modification concentration was 1M, the modification temperature was 40°C, and the modification was performed for 0.5 hours. Then move the bean curd to the aqueous solution to rinse until neutral. Dried at 30 °C to dry soybean hull biosorbent. Get 0.2g soybean hull biosorbent and 50ml Pb(NO 3 ) 2 Add the aqueous solution to a 150ml Erlenmeyer flask, and at room temperature, shake at a speed of 150dyn / m for 24 hours (adsorption equilibrium), and measure the metal ion Pb in the solution. 2+ The adsorption capacity is 93mg / g. The experimental results show that the adsorbent can be used in a wide range of pH = 2 to 11; then use 0.8M citric acid 100ml to desorb for 8 hours, wash with water until neutr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com