No pollution treatment technique for residue of refined terephthalic acid thin-film evaporator

A technology of purified terephthalic acid and thin-film evaporator, which is applied in water/sewage treatment, water/sludge/sewage treatment, centrifuged water/sewage treatment, etc. It can solve the problem of non-recyclable waste water, high cost, and land occupation. Large area and other problems, to achieve the effects of small footprint, closed loop, and low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

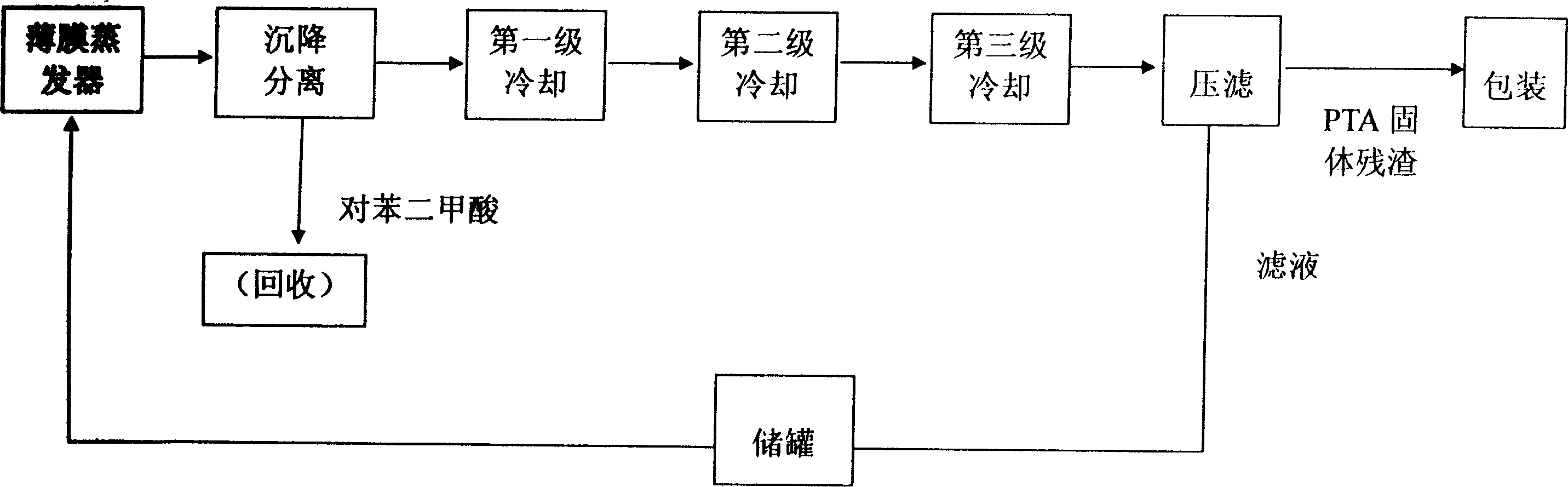

[0014] Such as figure 1 The shown clean terephthalic acid film evaporator residue pollution-free treatment process of the present invention has the following process steps:

[0015] a. Cooling: The waste liquid discharged from the thin-film evaporator is free to settle at 70°C to 90°C to separate terephthalic acid and recover it, and then the separated waste liquid is cooled to 10 ℃~50℃;

[0016] b. Separation: The cooled waste liquid is separated with a filter press, and the separated solid residue is directly bagged and sent to the treatment plant. The solid residue is treated with the "Pure Terephthalic Acid Residue Treatment Method" disclosed by Chinese patent CN1089365C Carry out comprehensive utilization and incineration treatment, the filtrate enters the storage tank, and is recycled as the beating water for the residue of the thin film evaporator. As the number of wastewater cycles increases, the content of cobalt and manganese in the wastewater gradually increases. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com