Method of preparing composite metal oxide thin film using hydrotalcite analog as precursor

A technology of oxide film and composite metal, applied in the direction of coating, surface reaction electrolytic coating, electrolytic coating, etc., can solve the problems of loose substrate bonding, uneven film surface, low practicability, etc., and achieve good adhesion, The particles are evenly dispersed to achieve the effect of wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

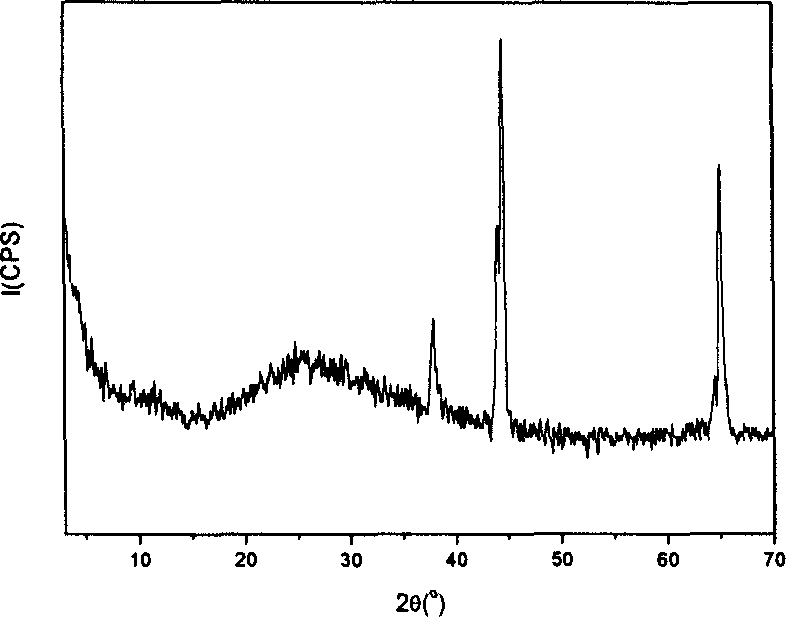

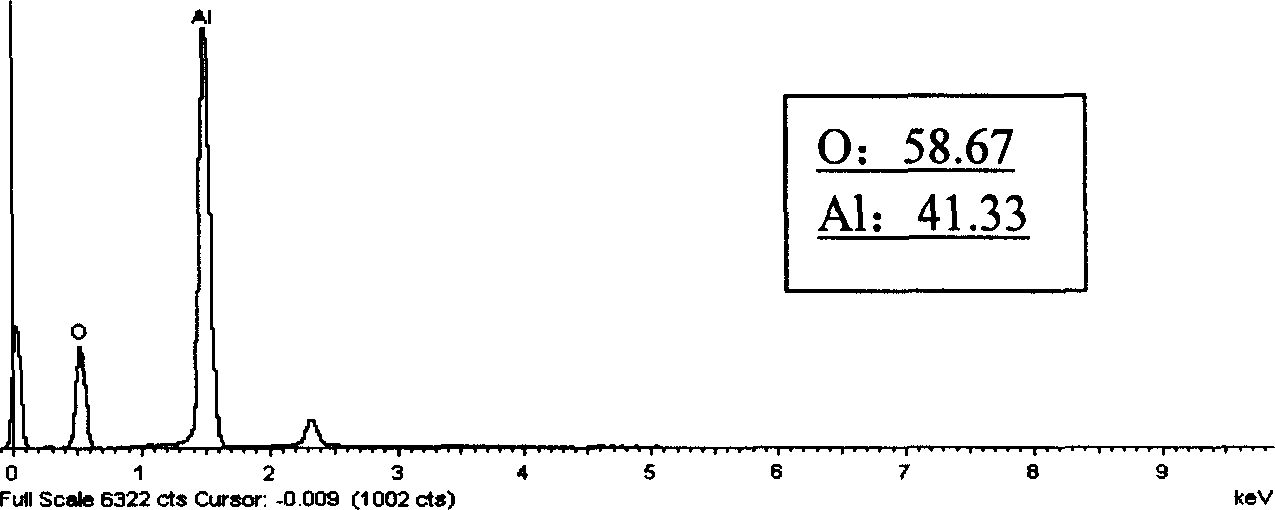

[0034] Step A: Ultrasonic cleaning the high-purity aluminum sheet in absolute ethanol and deionized water for 3 minutes, then dissolving it in 0.1M NaOH solution for 2 minutes, then rinsing it with deionized water for 1 minute, and putting the washed aluminum sheet in In the electrolytic cell, the aluminum sheet is used as the cathode, the lead sheet is used as the anode, and the sulfuric acid solution with a concentration of 1mol / l is used as the electrolyte for constant voltage oxidation. The working voltage is 16V, the current is 1A, the electrolysis time is 1h, and the electrolysis temperature is room temperature. The oxidation area of aluminum sheet is 10×7×2=126cm 2 . Take out the oxidized aluminum sheet, rinse off the residual acid solution on the surface with deionized water, dry it at 70°C for 12 hours, cut it into a size of 17mm×25mm, and tie thin wires on the two corners on the same side, Put in a desiccator for later use. From the X-ray diffraction pattern ( f...

Embodiment 2

[0038] Step A: the preparation method of anodized aluminum sheet is the same as that in Example 1

[0039] Step B: Weigh Co(NO 3 ) 2 ·6H 2 O 0.04362g, Ni(NO 3 ) 2 ·6H 2 O 0.1310g, urea 2.8829g, dissolved in 200ml deionized water, [Co 2+ ] / [Ni 2+ ]=1 / 3, [urea] / [M 1 2+ +M 2 2+ ] = 40. , the total ion concentration of divalent metals is 0.003mol / l, hang the AAO / Al substrate vertically in a glass reactor, and completely immerse the substrate in the reaction solution, use nitrogen protection, react in a water bath at 90°C for 6h, and then take it out The aluminum sheet was dried at 70° C. for 12 hours after rinsing off the reaction solution remaining on the surface with deionized water.

[0040] Step C: Place the dried hydrotalcite film precursor in a muffle furnace, raise the temperature from room temperature to 600°C at a heating rate of 5°C / min, and keep it at 600°C for 8 hours, and then cool down naturally by cooling with the furnace to room temperature. XRD and S...

Embodiment 3

[0042] Step A: the preparation method of anodized aluminum sheet is the same as that in Example 1

[0043] Step B: Weigh Ni(NO 3 ) 2 ·6H 2 O 1.3086g, Mg(NO 3 ) 2 ·6H 2 O 0.3846g, urea 2.8829g, dissolved in 200ml deionized water, [Mg 2+ ] / [Ni 2+ ]=1 / 3, [urea] / [M 1 2+ +M 2 2+ ]=4, the ion concentration of the total divalent metal is 0.03mol / l, the AAO / Al matrix is vertically suspended in a glass reactor, the AAO / Al matrix is completely immersed in the reaction solution, and reacted in an oven at 90°C for 48h, and then The aluminum sheet was taken out, and the reaction solution remaining on the surface was washed away with deionized water, and then dried at 70° C. for 12 hours.

[0044] Step C: Place the dried hydrotalcite film precursor in a muffle furnace, raise the temperature from room temperature to 600°C at a heating rate of 5°C / min, keep it at 600°C for 8 hours, and then cool down naturally to room temperature. A Ni / Mg / Al composite metal oxide film was obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com