Method of treating kitchen waste by using kitchen waste treating apparatus

A kitchen waste and treatment device technology, which is applied in biomass post-treatment, biomass pretreatment, biochemical cleaning devices, etc., can solve the problem that the mixing in the hydrolysis and acidification stage cannot be guaranteed, the phase separation cannot be completely realized, and the output of hydrolysis and acidification is reduced. VFA concentration and other problems in the liquid, to achieve the effect of being conducive to stable operation, improving the efficiency of hydrolysis and acidification, and improving the uniformity of pH

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. The kitchen waste is first crushed into a slurry, the mass percentage concentration of total solids (TS) is measured as 20%, the mass percentage concentration of volatile solids (VS) in TS is 95%, and the pH of the feed kitchen waste is 3.3. Dilute the kitchen waste with the effluent of the methanogenic reactor when feeding. The COD concentration of the diluted kitchen waste feed is 32g / L. The hydraulic retention time in the hydrolysis and acidification stage is 3 days. The feed COD of kitchen waste The load is 10g·(L·d) -1 ;

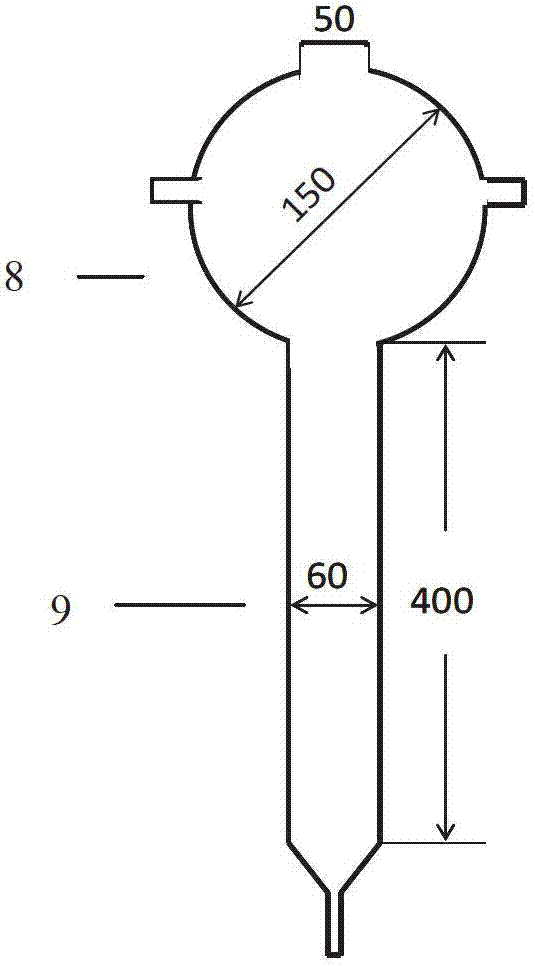

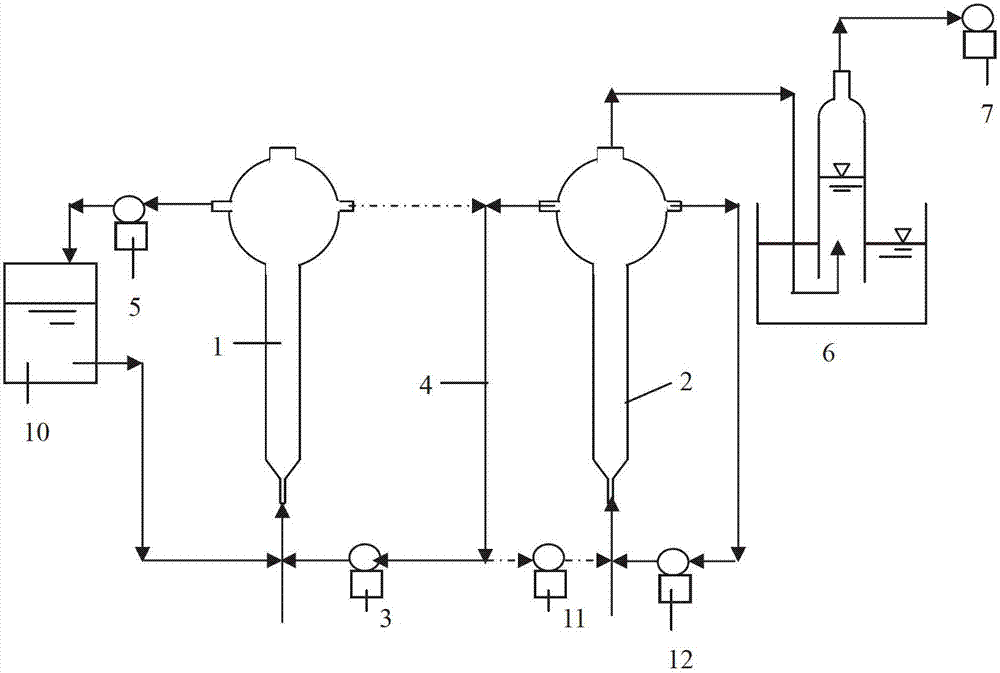

[0030] 2. The two-phase anaerobic digestion of kitchen waste is carried out in a glass reactor with an effective volume of 2L. figure 1shown. The reactor consists of a lower hollow elongated section 9 and an upper three-phase separator 8 . The lower elongated part has a diameter of 60mm and a height of 400mm; the upper spherical part has a diameter of 150mm. The two-phase anaerobic digestion process of kitchen waste operates intermittently...

Embodiment 2

[0035] 1. The kitchen waste is first crushed into a slurry, the mass percentage concentration of total solids (TS) is measured as 20%, the mass percentage concentration of volatile solids (VS) in TS is 95%, and the pH of the feed kitchen waste is 3.3. Dilute the kitchen waste with the effluent of the methanogenic reactor when feeding. The COD concentration of the diluted kitchen waste feed is 32g / L. The hydraulic retention time in the hydrolysis and acidification stage is 3 days. The feed COD of kitchen waste The load is 16g·(L·d) -1 ;

[0036] 2. The two-phase anaerobic digestion of kitchen waste is carried out in a glass reactor with an effective volume of 2L. figure 1 shown. The reactor consists of a lower hollow elongated section and an upper three-phase separator. The lower elongated part has a diameter of 60mm and a height of 400mm; the upper spherical part has a diameter of 150mm. The two-phase anaerobic digestion process of kitchen waste is operated in batch mode. ...

Embodiment 3

[0041] 1. The kitchen waste is first crushed into a slurry, the mass percentage concentration of total solids (TS) is measured as 20%, the mass percentage concentration of volatile solids (VS) in TS is 95%, and the pH of the feed kitchen waste is 3.3. Dilute the kitchen waste with the effluent of the methanogenic reactor when feeding. The COD concentration of the diluted kitchen waste feed is 32g / L. The hydraulic retention time in the hydrolysis and acidification stage is 3 days. The feed COD of kitchen waste The load is 20g·(L·d) -1 ;

[0042] 2. The two-phase anaerobic digestion of kitchen waste is carried out in a glass reactor with an effective volume of 2L. figure 1 shown. The reactor consists of a lower hollow elongated section and an upper three-phase separator. The lower elongated part has a diameter of 60mm and a height of 400mm; the upper spherical part has a diameter of 150mm. The two-phase anaerobic digestion process of kitchen waste is operated in batch mode. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com