Aluminum chlorate of polymerized silicic acid and preparation technique

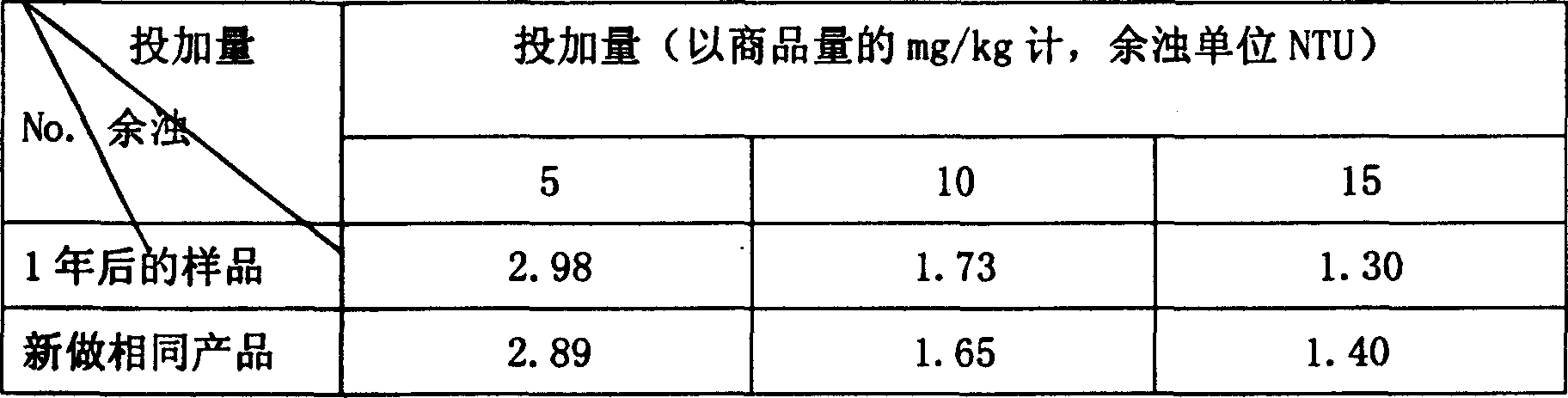

A kind of aluminum silicate chloride and preparation process technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of not particularly obvious effect, poor product stability, short storage time, etc., to improve the coagulation effect and low-cost production cost, the effect of improving the ability of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Weigh 100 grams of 10% hydrochloric acid, heat to 50°C, add 7.5 grams of calcium aluminate powder, the calcium aluminate powder contains Al 2 o 3 % is 55% (m / v), containing 33% (m / v) of total calcium, containing SiO 2 was 7.0% (m / v), and stirred for 1 hour to obtain 2 o 3 3.5% (m / v); containing SiO 2 0.48% (m / v) AlCl 3 Liquid, add 9 grams of calcium aluminate powder to the above liquid, keep it at 80-110°C for 3 hours to get Al-containing 2 o 3 7% (m / v); containing SiO 2 The product is 0.45% (m / v), salinity is 80%, density is 1.20 g / mg, and pH value is 3.5.

Embodiment 2

[0017] Weigh 100 grams of hydrochloric acid with a concentration of 15%, heat it to 50°C, add 11 grams of calcium aluminate powder, which contains Al 2 o 3 % is 50% (m / v), containing 30% (m / v) of total calcium, containing SiO 2 was 6.8% (m / v), and stirred for 1 hour to obtain 2 o 3 4.5% (m / v); containing SiO 2 0.8% (m / v) AlCl 3 Liquid, add 50 grams of water to the above liquid, add 13 grams of calcium aluminate powder, and keep it at 80-110 ° C for 3 hours to obtain Al-containing 2 o 3 6.5% (m / v); containing SiO 2 0.5% (m / v), a salinity of 80%, a density of 1.20 g / mg, and a pH of 3.5.

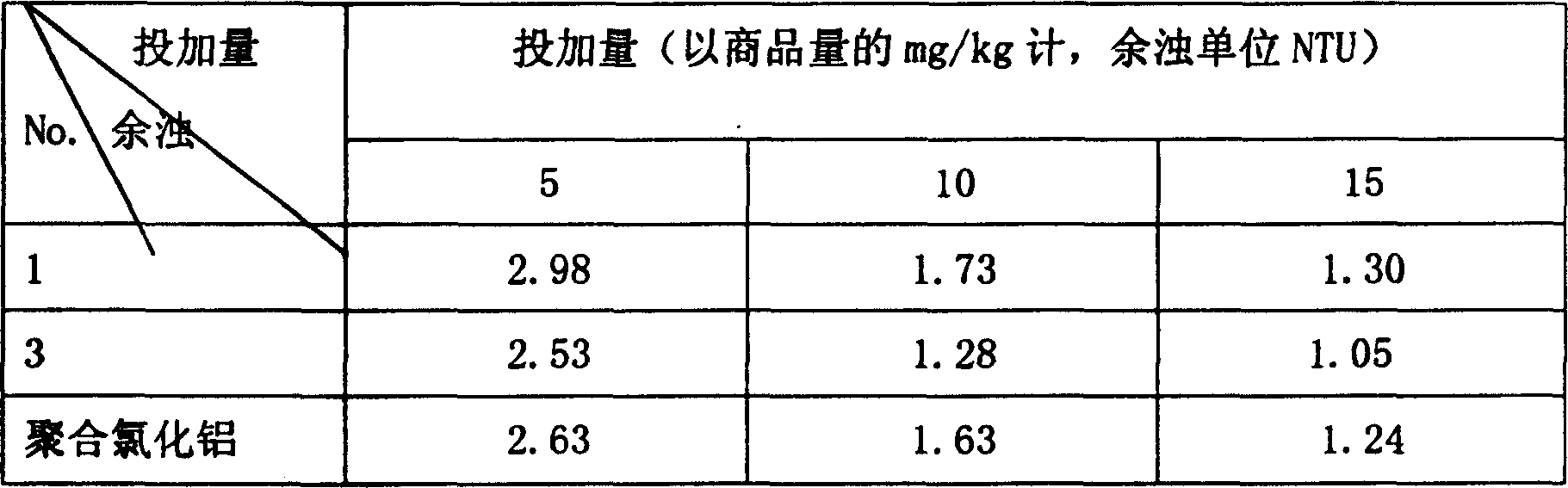

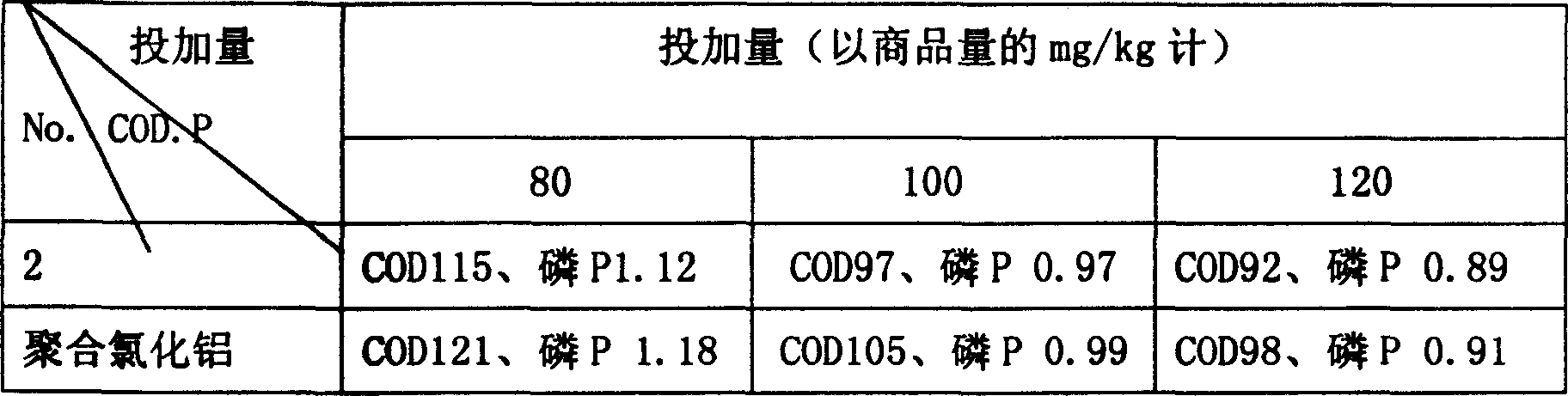

[0018] The following are the synthetic formula and the product ingredient table of the polyaluminum silicate chloride of the embodiment 1-4, and the preparation process of the embodiment 3-4 is the same as that of the embodiment 2.

[0019] No.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com