Anti disruptive self-dense concrete of mixed fiber under high temperature of fire

A self-compacting concrete and hybrid fiber technology, applied in the field of concrete, can solve problems such as poor anti-burst performance, achieve no noise pollution, improve safety reserves, and reduce the degradation of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

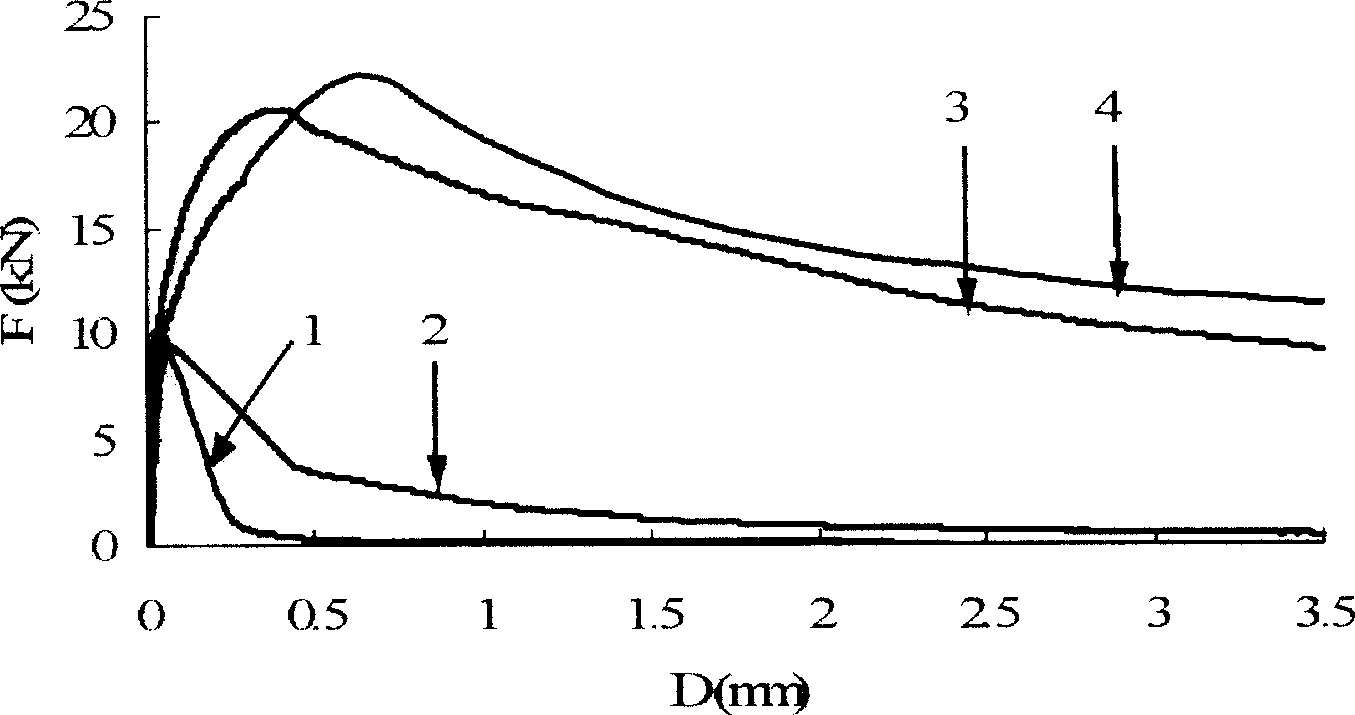

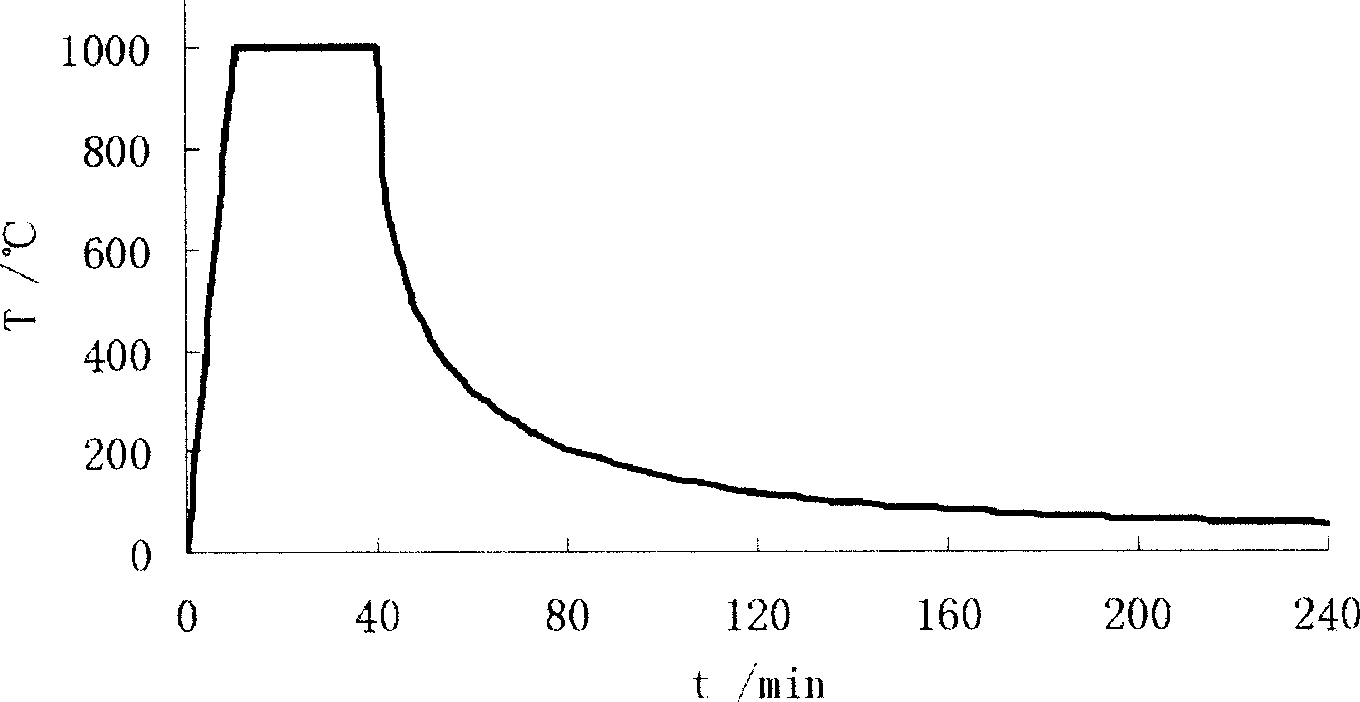

[0032] The explosion resistance of hybrid fiber self-compacting concrete under fire high temperature has been verified in experimental research. For comparison, ordinary self-compacting concrete without fiber, self-compacting concrete with synthetic fiber alone and self-compacting concrete with steel fiber alone are also configured. The mix ratio of self-compacting concrete is shown in Table 1, and the material parameters are shown in Table 2.

[0033] Use the method of dry mixing first and then wet mixing, that is, first put cement, sand, gravel, and fly ash into the mixer for dry mixing for 1 to 2 minutes, then evenly sprinkle synthetic fibers and steel fibers, and then dry mix for 1 to 2 minutes. Finally, add evenly mixed water and water reducing agent, stir for 2 to 3 minutes and discharge.

[0034] Material

water

the sand

pebbles

synthesis

fiber

steel fiber

Ord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com