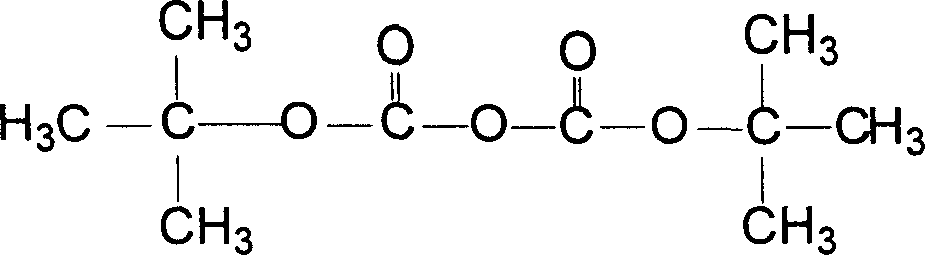

Method for preparing di-tert-butyl dicarbonate

A technology of di-tert-butyl and dicarbonic acid, which is applied in the field of preparation of di-tert-butyl dicarbonate, can solve the problems of difficult product purification, low reaction yield, large dosage, etc., and achieve good product purity, convenient process operation, The effect of less waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example 1

[0025] Add 40g of sodium tert-butoxide into a 500ml four-neck flask, then add 320ml of n-hexane and stir. When the temperature drops to 12°C, start to introduce carbon dioxide, and keep warm for 1 hour after aeration. Add the catalyst, add 21g of Shuangguang in batches at 15°C, keep warm for 2 hours after the addition, and then take samples for analysis. After the reaction was completed, 100ml of water was added, stirred for 30 minutes, the lower water phase was separated, the oil phase was filtered, and the filtrate was concentrated, crystallized, and suction filtered to obtain a white crystalline solid. Dry under reduced pressure to obtain 25 g of the product di-tert-butyl dicarbonate.

specific example 2

[0027] Add 40g of sodium tert-butoxide into a 500ml four-necked bottle, then add 320ml of n-hexane and stir. When the temperature drops to 12°C, start to feed carbon dioxide, and keep warm for 1 hour after ventilation. Add the catalyst, add 20.5g Sanko in batches at 15°C, keep the temperature for 2 hours after the addition, and then take samples for analysis. After the reaction was completed, 100ml of water was added, stirred for 30 minutes, the lower water phase was separated, the oil phase was filtered, and the filtrate was concentrated, crystallized, and suction filtered to obtain a white crystalline solid. Dry under reduced pressure to obtain 26 g of di-tert-butyl dicarbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com