System and method for monitoring breed of edible fungus

A technology of monitoring system and edible fungus, which is applied in general control system, control/regulation system, computer control, etc., can solve the problems of affecting regulation, complicated process, and difficulty in effective regulation, so as to improve work efficiency, save human resources, realize The effect of automatic collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

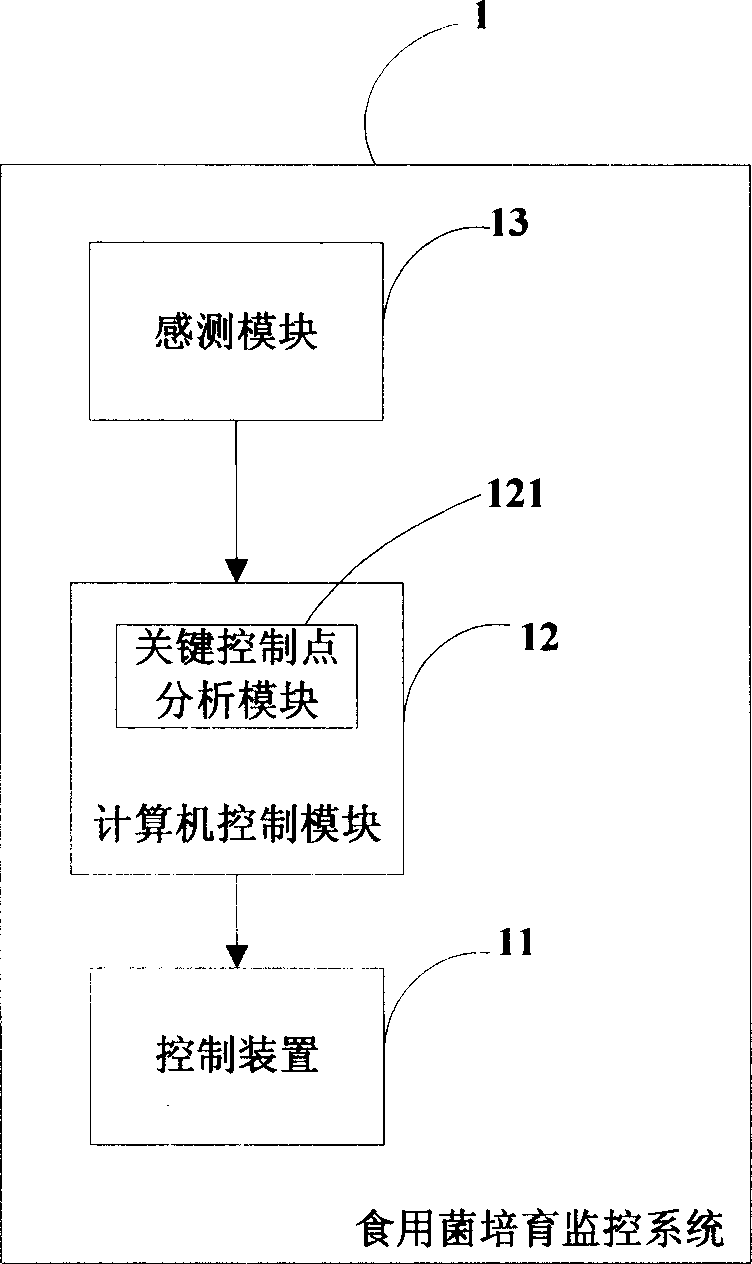

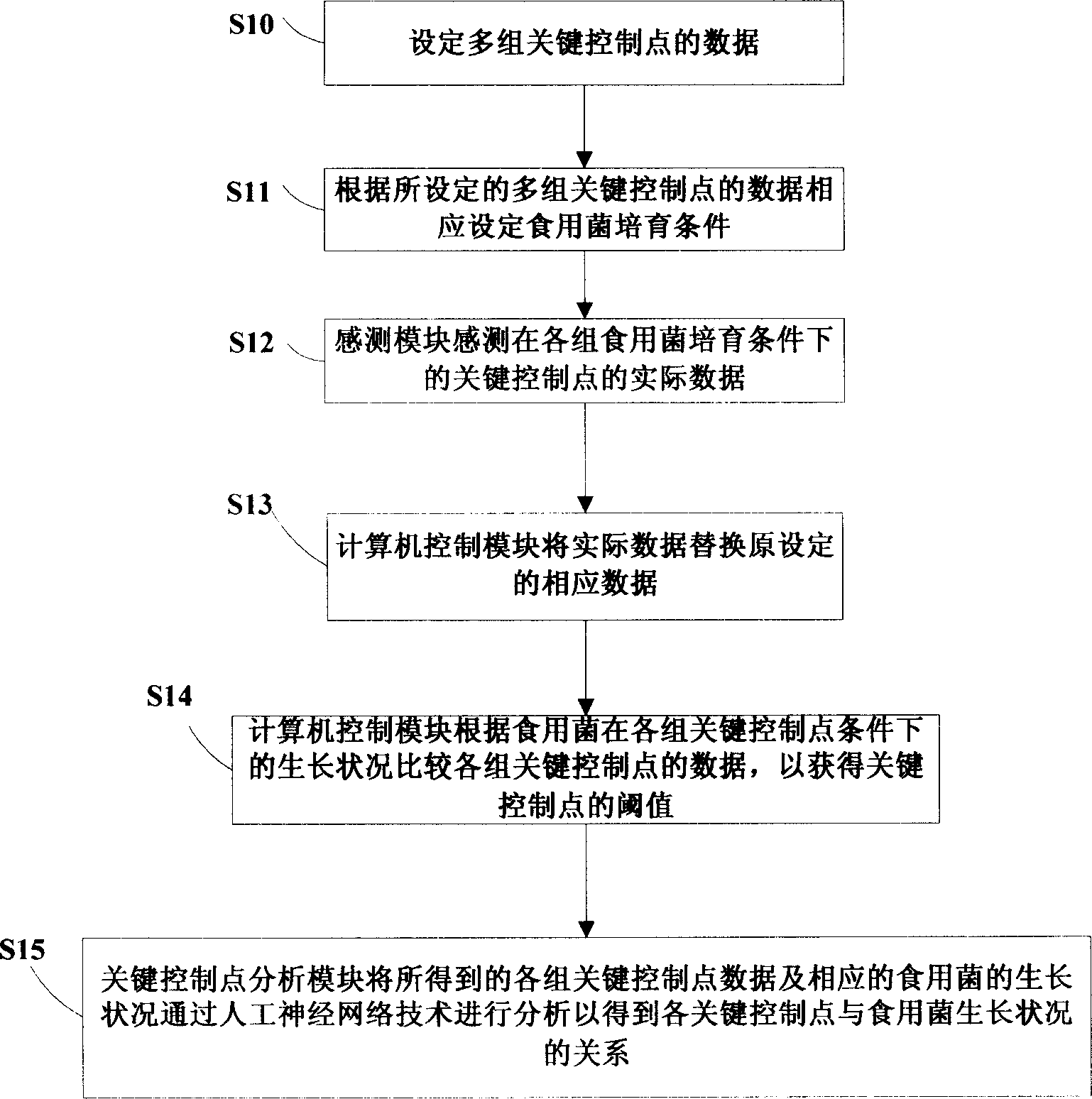

[0014] See figure 1 , the present invention provides a monitoring system 1 for cultivating edible fungi, wherein there are a plurality of critical control points affecting the safety, sanitation and quality of edible fungi in the cultivating of edible fungi. The key control points proposed by the system related to material requirements, water safety and production conditions, including the annual inspection of raw materials, water content in bottling, PH value in bottling, average weight in bottling, stirring temperature, sterilization time, cultivation There are 15 key control points including anti-pollution rate, water content of scratch bacteria, pH value of scratch bacteria, sensory value on the 9th day of bud reminder, occurrence rate of Stropharia, storage temperature, fresh air filtration, colony growth and uniformity (As shown in Table 1 below).

[0015] serial number

1

2

3

4

5

6

7

8

key control

s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com