Method of preparing Mo-Cu alloy through field-assisted activated sintering

An activation sintering and field-assisted technology, applied in the field of refractory metal processing, can solve the problems of restricting the popularization and application of Mo-Cu alloy, reducing the performance of Mo-Cu alloy, large mold consumption, etc., and shortening the preparation cycle and sintering time. , the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~16

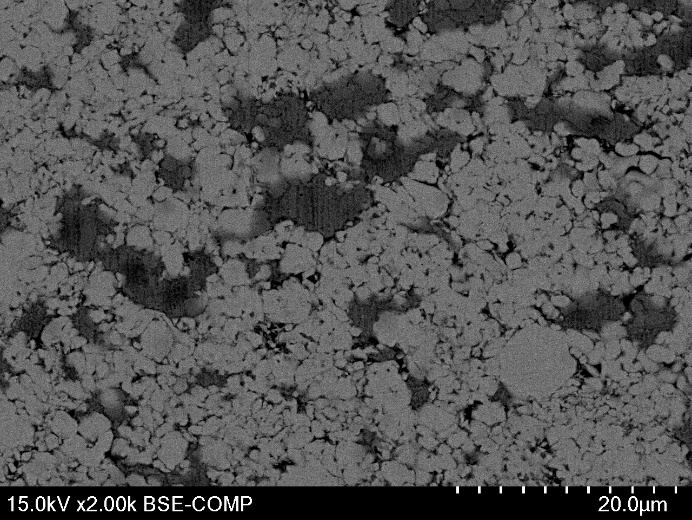

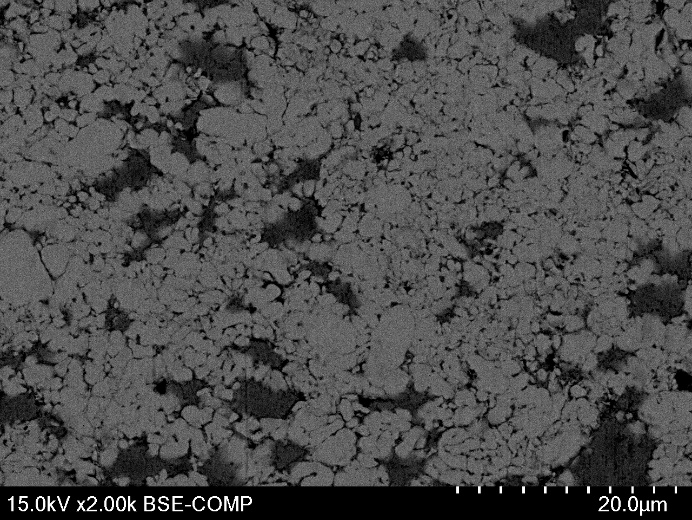

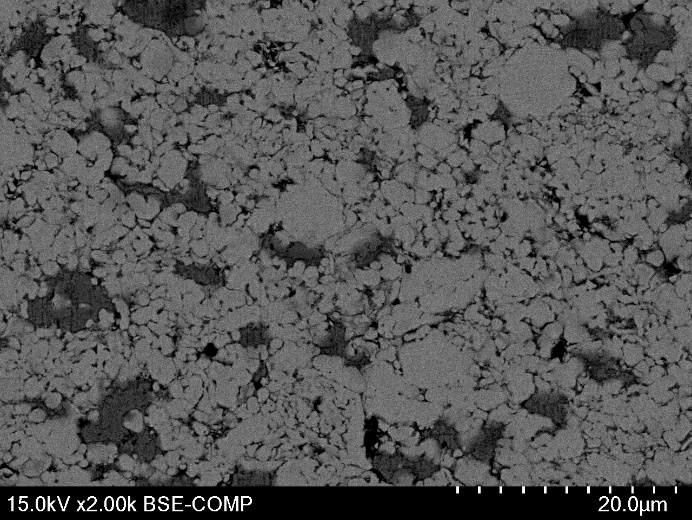

[0026] 1. Mix molybdenum powder with a particle size of 3~15μm and copper powder with a particle size of 1~15μm according to the mass percentages listed in the table, and then put them into a high-energy planetary ball mill for wet grinding and vacuum drying to obtain Mo-Cu mixed powder.

[0027] 2. Put the Mo-Cu mixed powder into the mold and press it into a green compact of a certain shape.

[0028] 3. Place the compact in the sintering equipment, in an electric field with an output voltage of 3~10V and an output current of 20000~50000A, the vacuum degree is higher than 10 -1 Under the condition of Pa, the green compact is directly energized for rapid heating, so that the temperature of the compact is raised to 750-900 °C at a heating rate of 10-75 °C / s, and a pressure of 5-20 MPa is applied to both ends of the sample, and then kept for 3 After ~10min, turn off the power to obtain Mo-Cu alloy.

[0029] 4. During the sintering process, the shape of the green body remains in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com