Nitride semiconductor vertical cavity surface emitting laser

A technology of vertical cavity surface emission and nitride semiconductor, which is applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems of limiting optical gain performance, and achieve the effects of low heat generation, high optical gain performance, and low voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

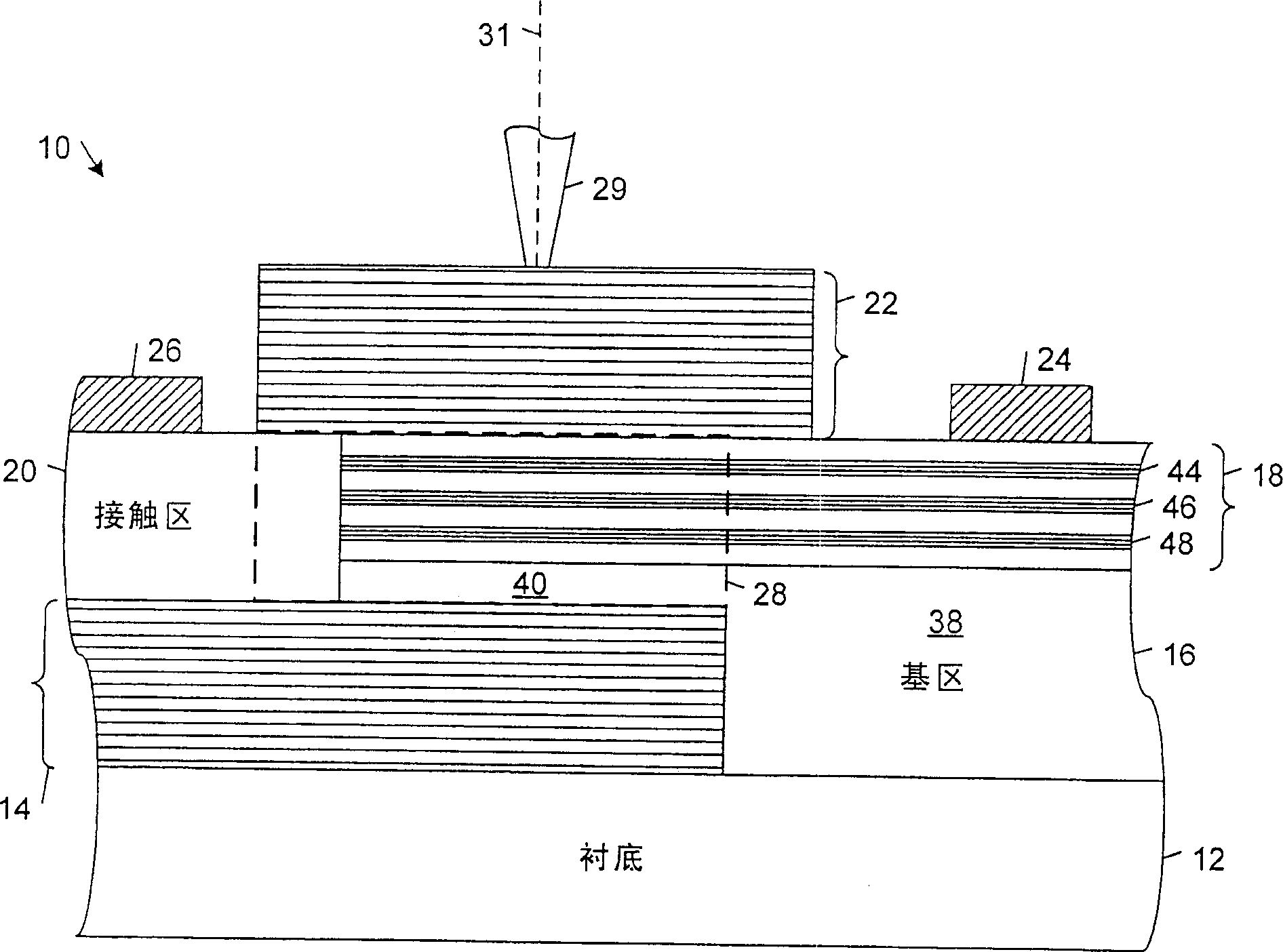

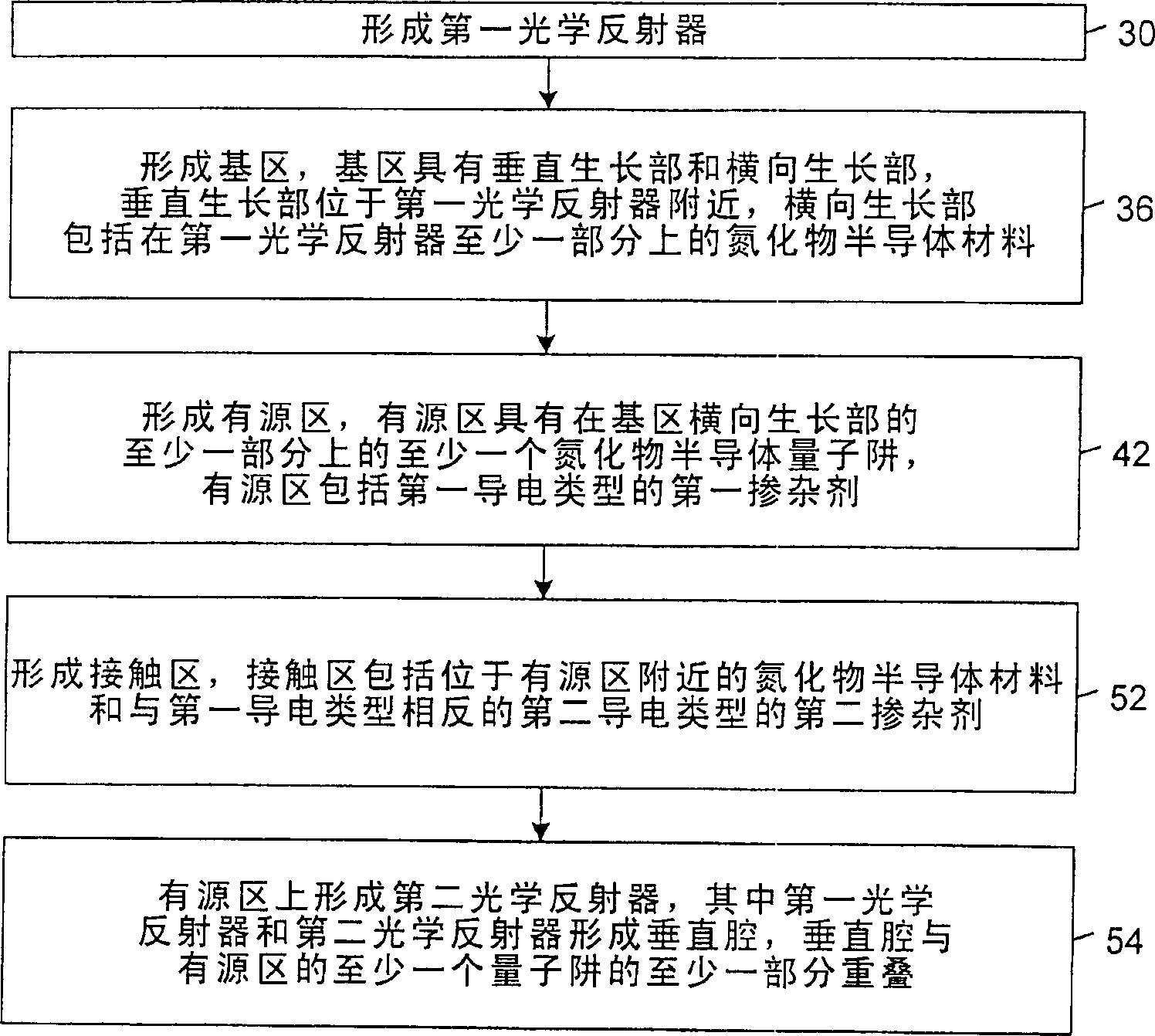

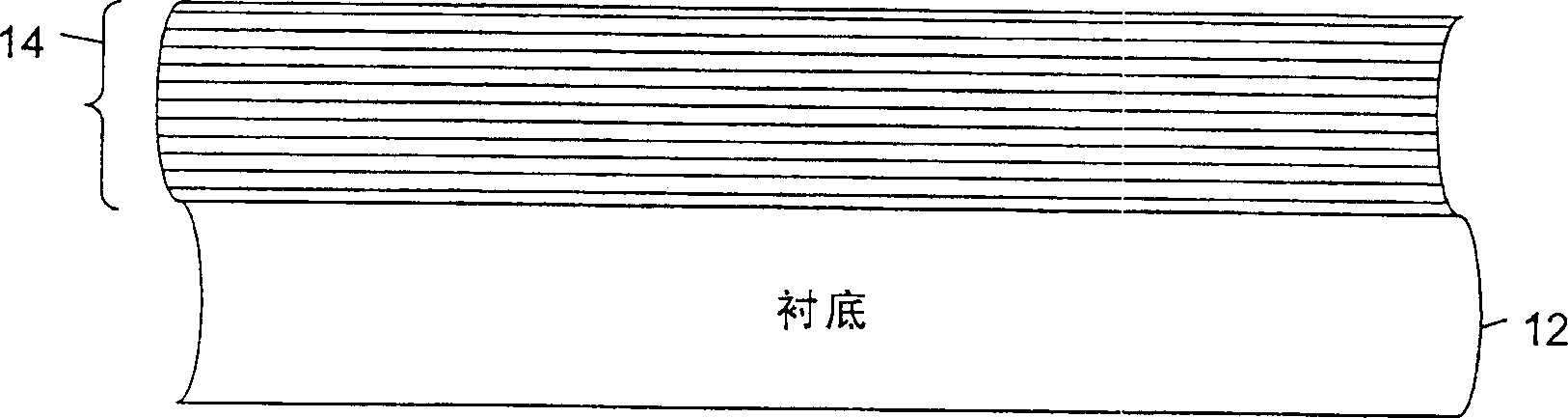

[0011] In the following description, similar reference numerals are used to designate similar elements. Moreover, the drawings are intended to show major configurations of exemplary embodiments in diagrammatic form. The drawings are not intended to depict every configuration of actual embodiments and the relative dimensions of the depicted elements are not drawn to scale.

[0012] As used herein, the term "nitride semiconductor material" refers to a nitrogen-containing Group III-IV semiconductor material. Exemplary nitride semiconductor materials include gallium nitride (GaN), indium gallium nitride (InGaN), indium nitride (InN), aluminum gallium nitride (AlGaN), aluminum nitride (AlN), aluminum indium gallium nitride ( AlInGaN), gallium arsenide nitride (GaAsN), indium gallium arsenide nitride (InGaAsN), aluminum gallium arsenide nitride (AlGaAsN), gallium phosphide nitride (GaPN), indium gallium phosphide nitride (InGaPN) and aluminum gallium phosphonitride compound (AlGaP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com