Method and device for natural gas hydrate exploitation with in-situ catalytic oxidation thermochemistry method

A technology of in-situ catalysis and catalytic oxidation, which is applied in the fields of mining minerals, mining fluids, and earthwork drilling, etc., can solve the problems of low energy utilization efficiency, complex mining equipment, large heat loss, etc., to avoid geological and environmental disasters, speed up Mining rate, ensure stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

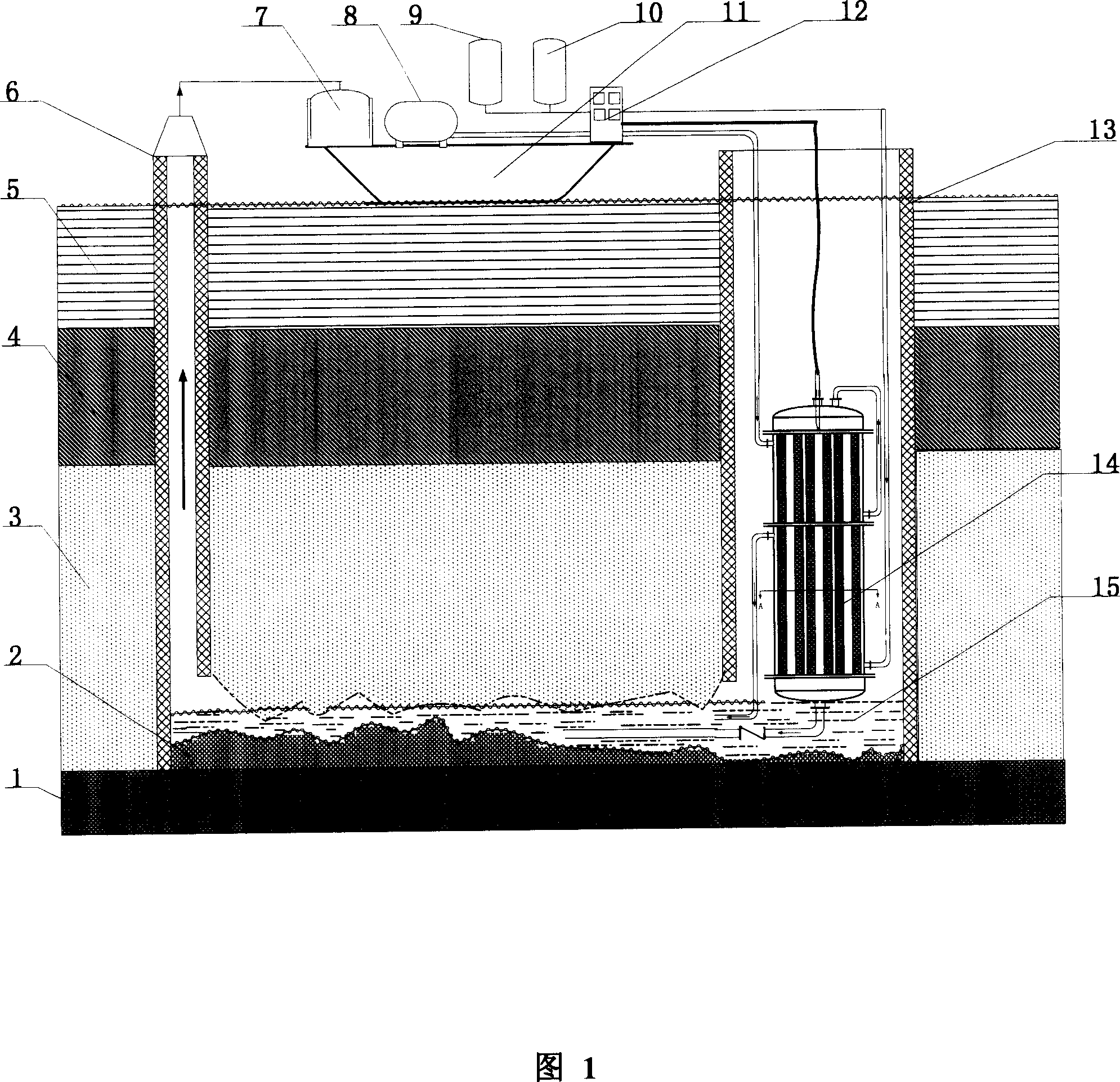

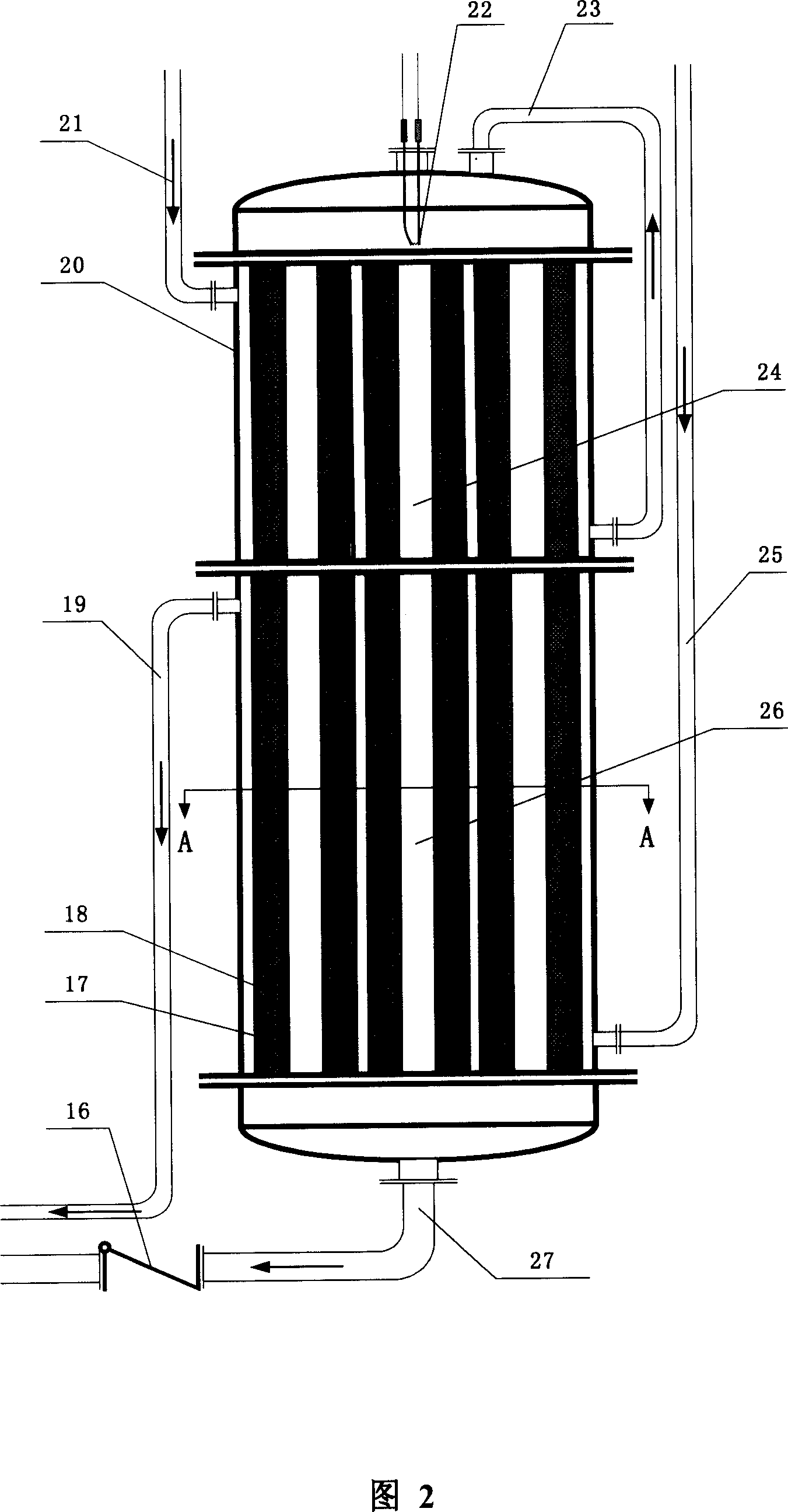

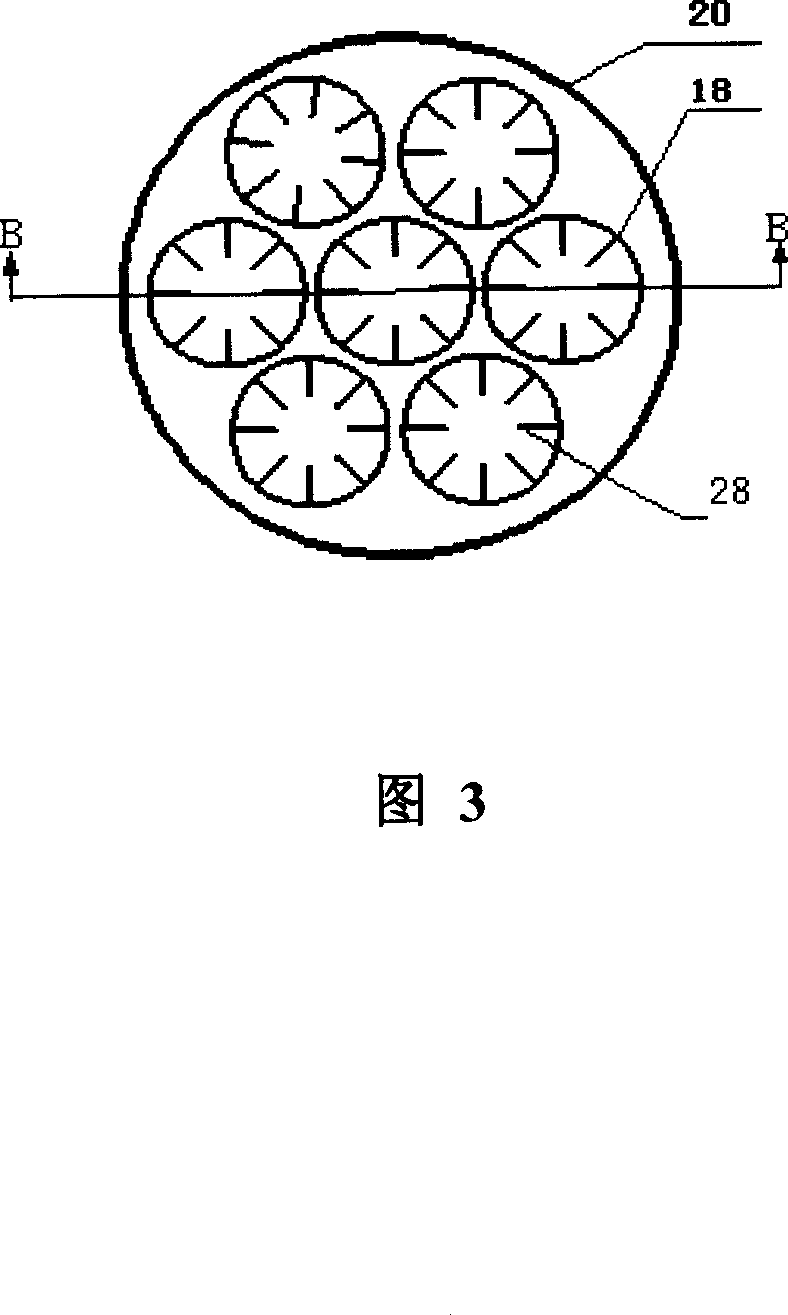

[0052] As shown in Figures 1, 2, and 3, firstly, the deepwater drilling technology is used to construct the production well 13 and the gas collection well 6 on the seabed, and at the same time, the horizontal connection channel between the production well and the gas collection well is opened, so that the production well 13 and the gas collection well 6 pass through the seawater Layer 5 and seabed sediment layer 4 penetrate to the bottom of gas hydrate reservoir 3 . A catalytic oxidation burner 14 is installed in the production well. During the mining process, CH with a volume ratio of 1:10 4 Mixed with air in the fuel tank 8, the mixed fuel gas enters the burner preheating section 24 through the fuel and oxidant inlet pipe 21, preheats to 400-600°C, and then enters the catalytic oxidation burner through the catalytic oxidation burner inlet pipe 23 Tube 18. The inner tube 18 of the catalytic oxidation burner consists of a plurality of inner tubes with fins 28 fixed on the tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com