Underwater blast shaped charge and underwater distribution method

A technology of energy accumulation and blisters, which is applied in blasting, blasting cylinders, explosive charges, etc., to achieve the effects of cost reduction, convenient construction and low initial investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

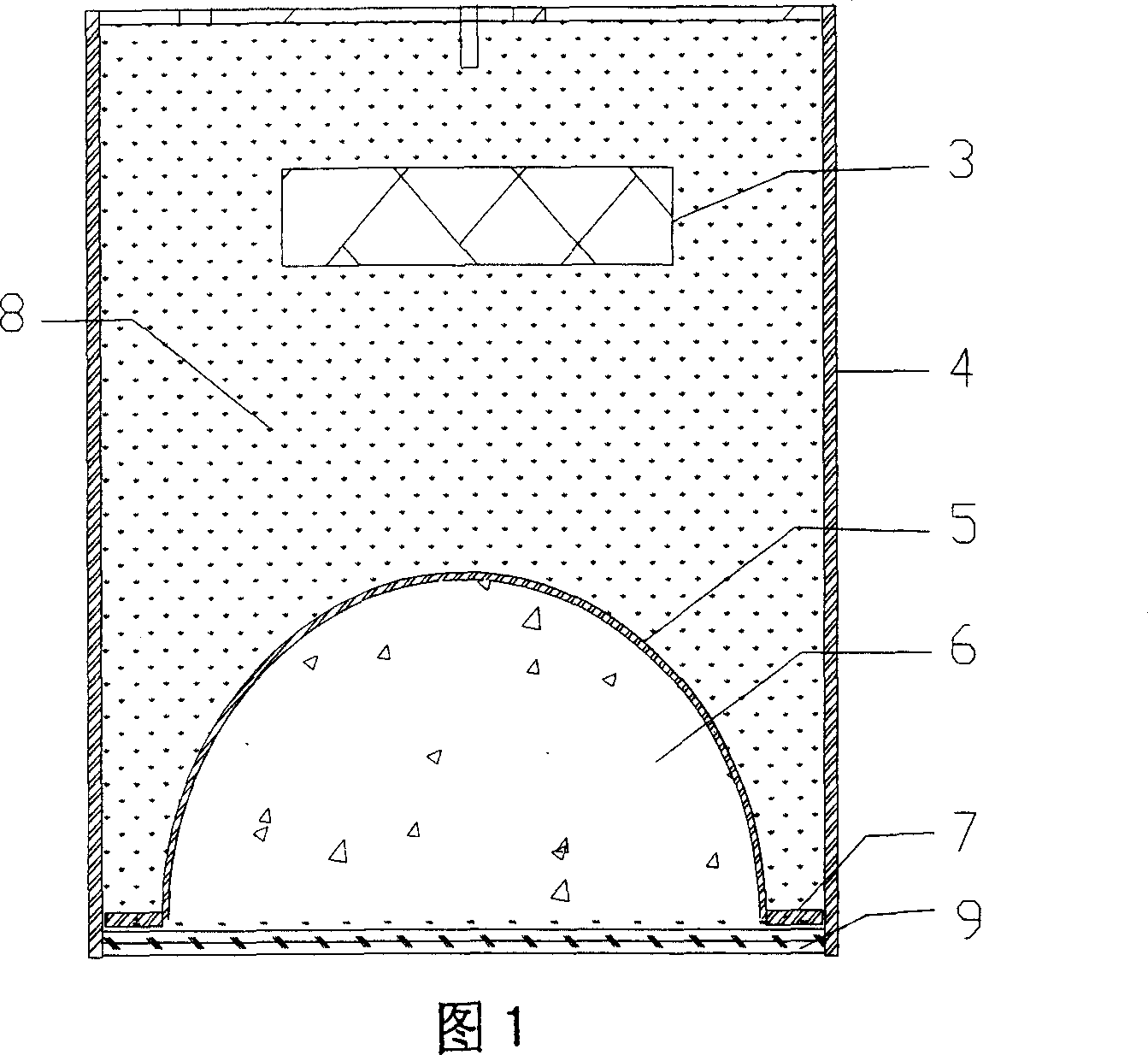

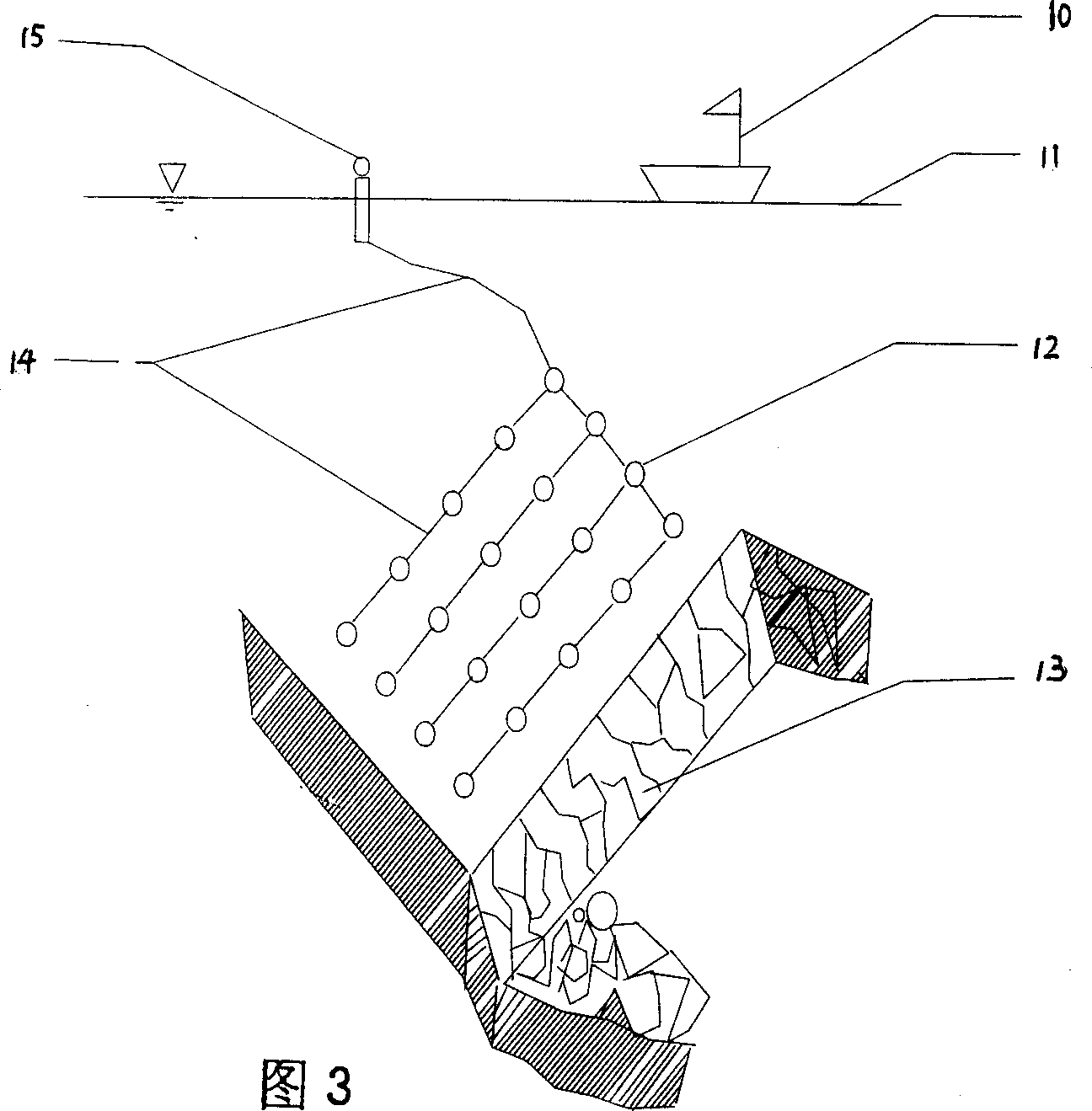

[0060] This example is an experiment. The test blasting rock is an optional piece of granite under still water with a flat rock surface and a thickness of about 2m, and the water depth is 2.2m.

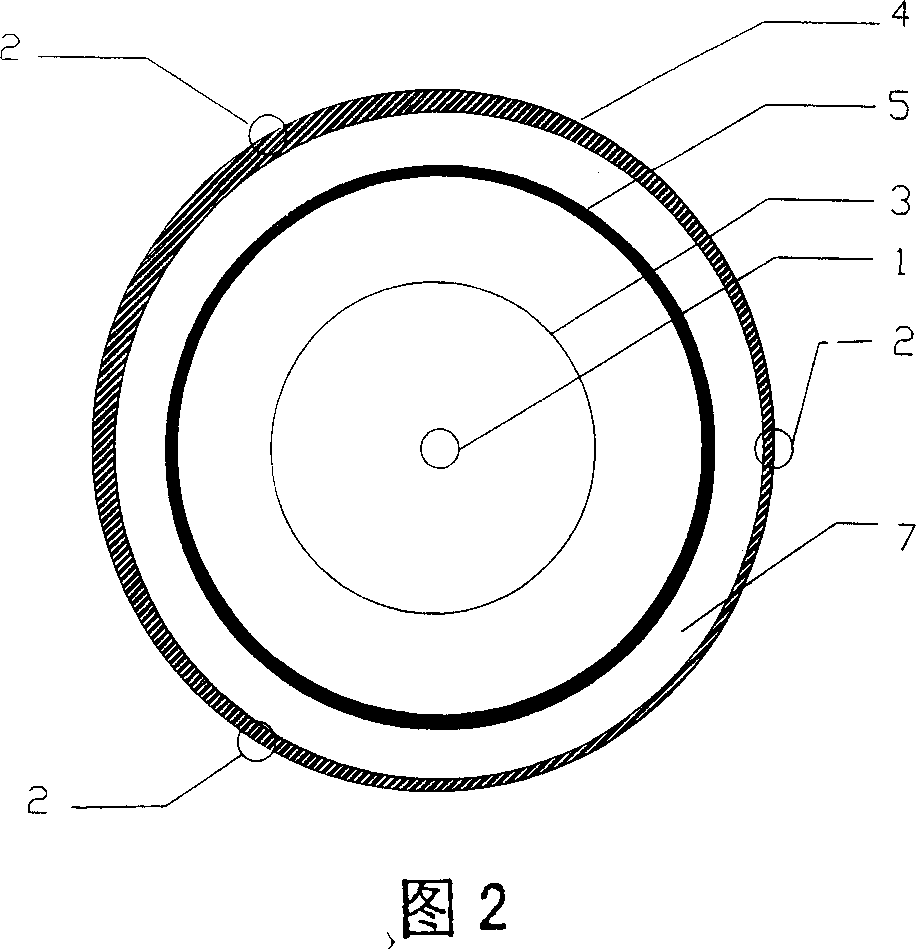

[0061] The production process of the shaped energy bomb: the shell is a seamless steel pipe with an outer diameter of 273mm and a wall thickness of 8mm. First, cut the steel pipe into 250mm short steel pipes, and polish the two cut sections into smooth edges and corners to avoid straight edges and corners; according to the selected steel pipe model and referring to engineering data, the diameter of the bottom periphery of the energy-gathering cover is determined to be 200mm, and the energy-gathering cover is made of 2mm steel plate Stamping into a hemispherical shape requires that the processed energy-gathering cover should be uniform in thickness, regular in shape, smooth and free of burrs around the bottom of the cover; the energy-gathering cover and the shell steel pipe are welded ...

example 2

[0065] The test blasting rock is the bedrock (fully weathered rock, strongly weathered rock and moderately weathered rock) of the Xiamen Port Dongdu Channel Expansion Project. The underwater rock surface is relatively flat, and the rock surface is 4.5m below the reference water level. m, the water velocity is less than 0.5m / s.

[0066] The shell of the shaped energy bomb is a steel pipe with an outer diameter of 245mm and a wall thickness of 6.5mm. The projectile height is 220m, and the energy-gathering cover is hemispherical, with a radius of 90mm and a thickness of 2mm. The polyvinyl chloride foam plastic is processed into a hemispherical shape with a radius of 90mm and bonded together with the energy gathering cover. A single shaped charge pack weighs 10kg.

[0067] The explosives used in shaped energy bombs are cast TNT explosives with a density of 1.56g / cm 3 , the detonation velocity exceeds 6500m / s. A detonator detonator is used to detonate the shaped charge, and a w...

example 3

[0070] A water intake tower has an outer diameter of 10m, an inner diameter of 8m, a height of 47.8m, and a weight of more than 3,000 tons. It is 260m away from the reservoir dam and 103m away from the sluice house. During construction, the foundation needs to be dug for 5-6m at a water depth of 33m, about 500m 3 . The surface layer has a gravel layer of about 2m, and the lower part is moderately weathered granite.

[0071] The shell of the shaped energy bomb is cylindrical with an outer diameter of 560mm, a height of 500m, and a wall thickness of 2mm, and is made of a 2mm thick steel plate. The energy-gathering cover is hemispherical, with a radius of 220mm. The connecting ring and the energy-gathering cover are integrally formed by punching steel plates with a thickness of 4mm. The polyvinyl chloride foam plastic is processed into a hemispherical shape with a radius of 220mm and bonded together with the energy gathering cover. The main explosive is cast TNT explosive with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com