Method of separating NaOH in sodium aluminate solution in aluminum oxide producing process

A technology for producing sodium aluminate and alumina, which is applied in the purification of aluminate/alumina/aluminum hydroxide, the preparation of alkali metal aluminate/alumina/aluminum hydroxide, chemical instruments and methods, etc. Evaporated mother liquor caustic ratio, large amount of extractant oil, etc., to achieve the effect of easy continuous operation, small footprint and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

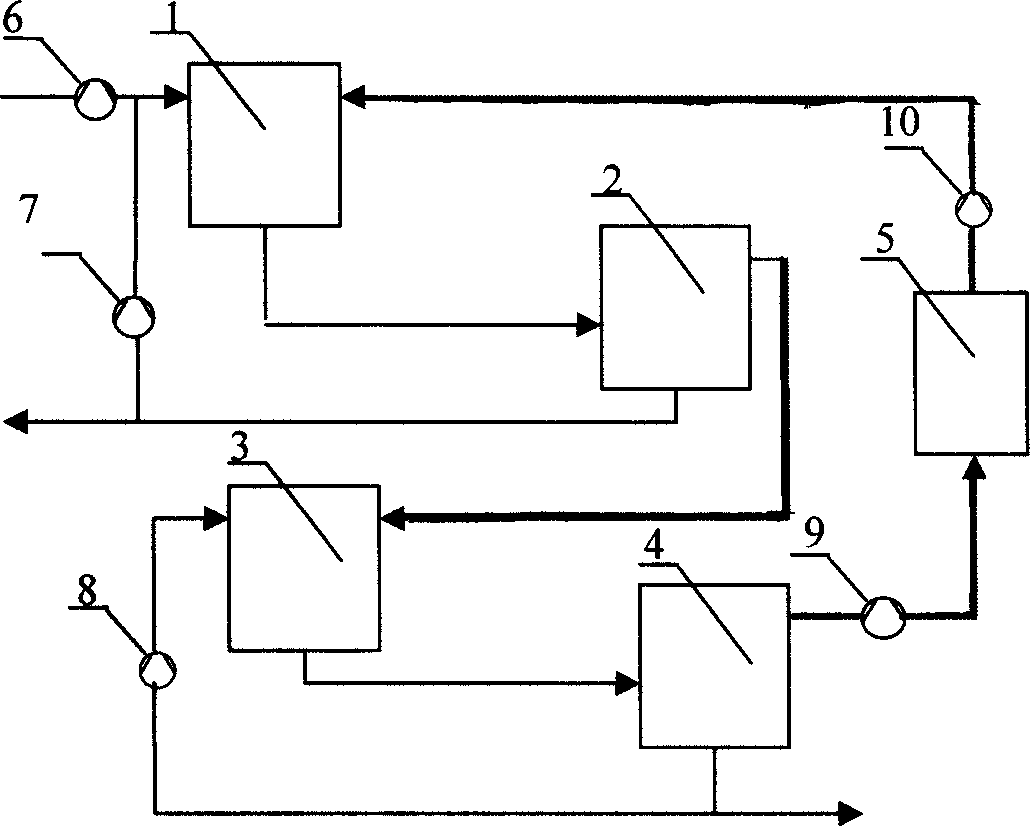

Method used

Image

Examples

Embodiment 1

[0026] Raw materials: Sodium aluminate solution comes from an alumina plant, the chemical composition is N K 320g / L, Al 2 o 3 178.4g / L, caustic ratio 2.95; stripping solution—chemical composition of decomposition mother liquor is N K 165g / L, Al 2 o 3 93.6g / L, caustic ratio 2.90, extractant is C 8 ~C 10 of fatty alcohols.

[0027] 38-stage extraction, extraction temperature 90°C; 10-stage back-extraction, back-extraction temperature 90°C; extraction ratio 1:1, back-extraction ratio 2:1; distillation temperature 110°C. After extraction with sodium aluminate solution, N K is 370g / L, and the caustic ratio is 1.59; the N K It is 247g / L, and the caustic ratio is 3.4.

Embodiment 2

[0029] Raw material is with embodiment 1.

[0030] 40-stage extraction, extraction temperature 86°C; 18-stage back-extraction, back-extraction temperature 86°C; extraction ratio 1:1, back-extraction ratio 1:1; distillation temperature 125°C. After extraction with sodium aluminate solution, N K is 376g / L, and the caustic ratio is 1.55; the N K It is 226g / L, and the caustic ratio is 3.18.

Embodiment 3

[0032] Raw material is with embodiment 1.

[0033] 45-stage extraction, extraction temperature 92°C; 7-stage back-extraction, back-extraction temperature 92°C; extraction ratio 1:1, back-extraction ratio 2.5:1; distillation temperature 140°C. After extraction with sodium aluminate solution, N K is 386g / L, and the caustic ratio is 1.50; the N K It is 250g / L, and the caustic ratio is 3.47.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com