Composite plating coat material for metallurgy conticaster crystallizer, preparation method and apparatus thereof

A composite coating and crystallizer technology, applied in the surface field, can solve the problems of poor wear resistance and low service life of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Using controlled current direct current electroplating method to composite Ni-diamond nickel-based composite coating on the inner wall of flat metallurgical continuous casting mold

[0039] Plating bath composition: NiSO 4 ·6H 2 O 300g / L

[0040] NiCl 2 ·6H 2 O 10g / L

[0041] H 3 BO 3 10g / L

[0042] Diamond nanoparticles (particle size d=3nm) 0.1g / L

[0043] Lauric acid diacetamide 5g / L

[0044] Sodium lauryl sulfate 0.01g / L

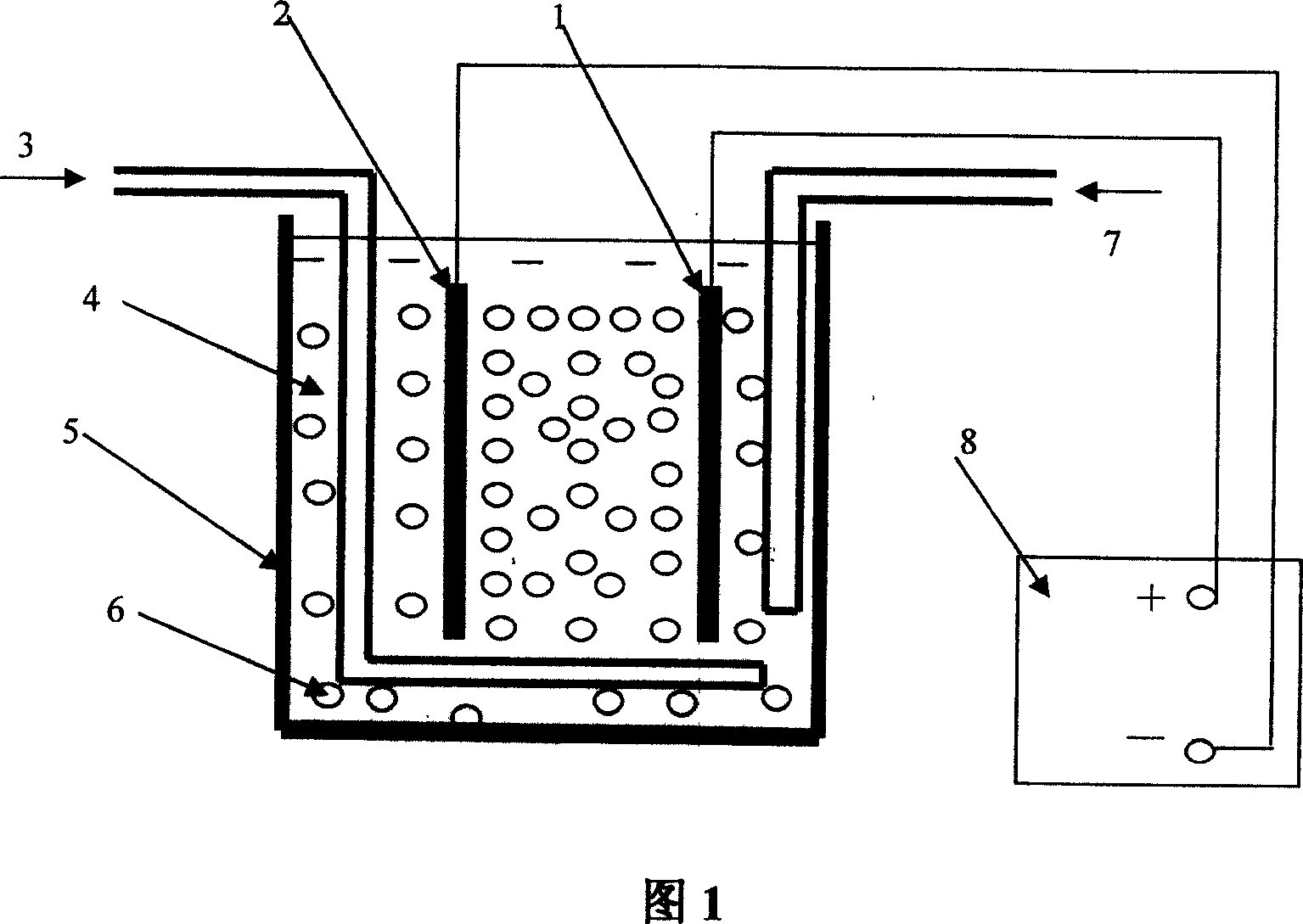

[0045] Nickel-based composite plating system: The nickel-based composite plating system is shown in Figure 1. The nickel-based composite plating solution 4 is prepared according to the composition of the above composite plating solution. Air 3 is introduced into the plating solution through a pipe, and the plating solution 4 is stirred under the action of a large number of air bubbles 6. In the rectangular plating tank 5, the plating solution in the plating tank is stir...

Embodiment 2

[0048] Example 2: Electroplating Ni-SiC-TiN nickel-based composite coating on the inner wall of the cylindrical mold using controlled current pulse electroplating

[0049] The composition of the composite plating solution is: Ni(BF 4 ) 2 500g / L

[0050] HBF 4 5g / L

[0051] H 3 BO 350g / L

[0052] Sodium lauryl sulfate 0.1g / L

[0053] Sodium polymethacrylate 15g / L

[0054] SiC (average particle size 1.2μm) 100g / L

[0055] TiN (average particle size 50nm) 5g / L

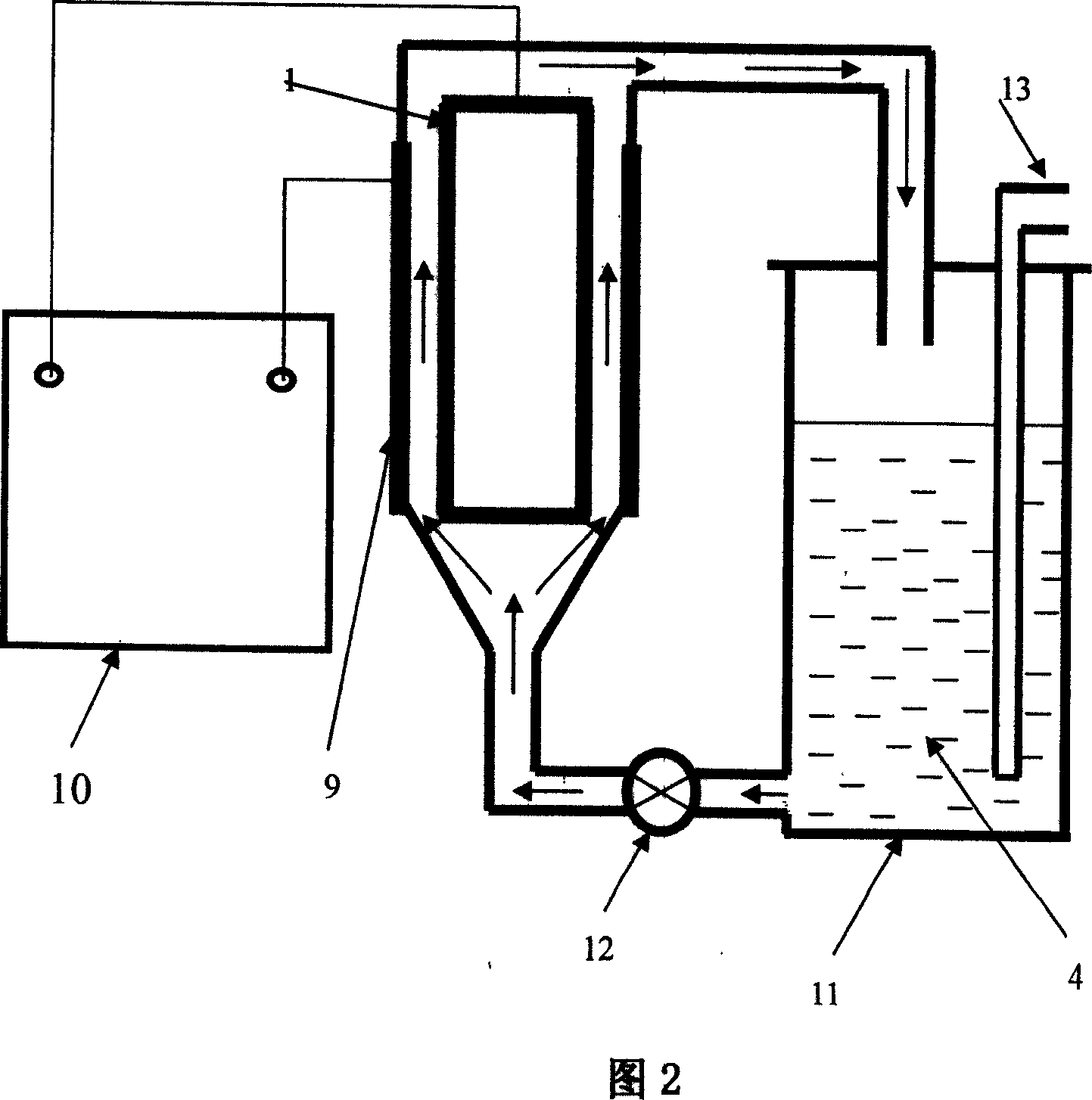

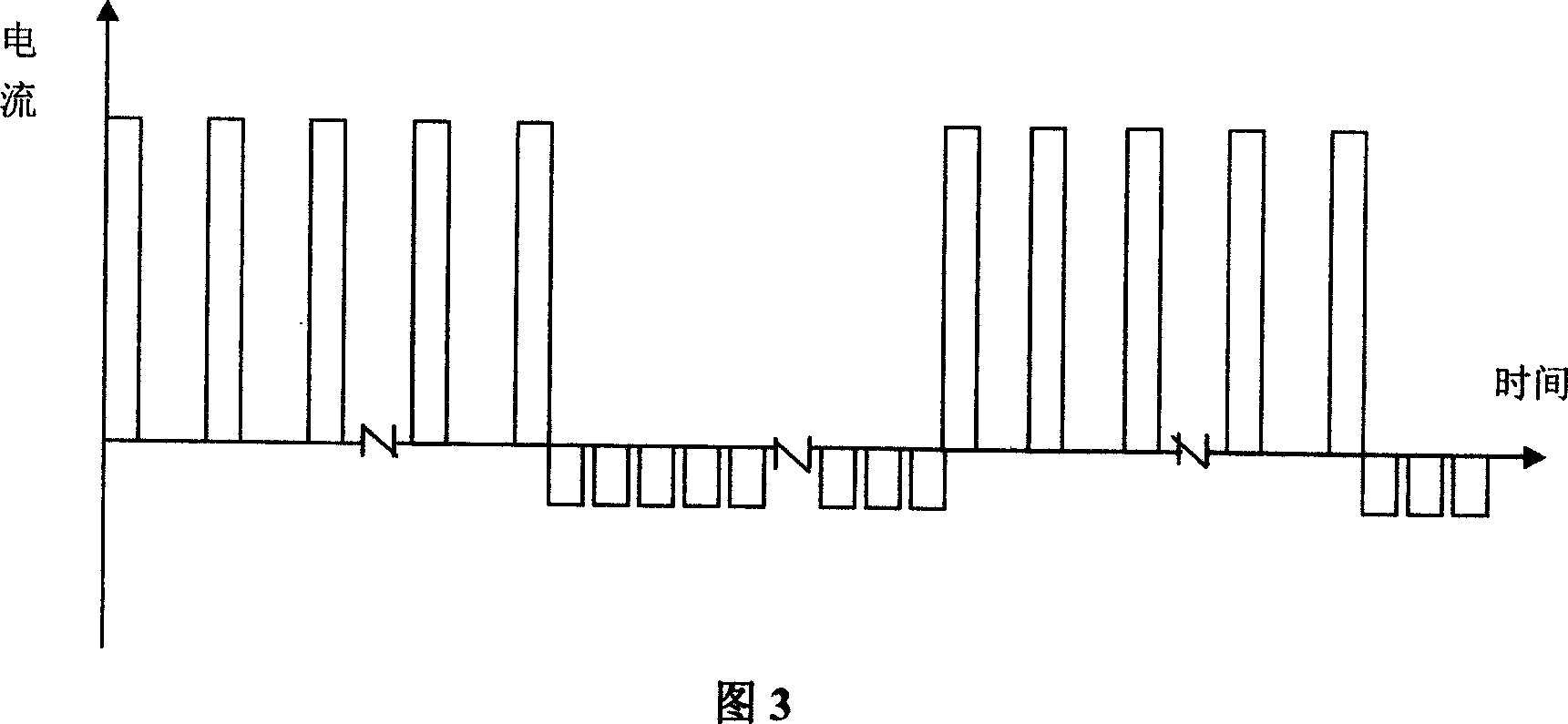

[0056] Nickel-based composite plating system: Figure 2 shows the use of a circulating pump 12 for liquid flow circulation, with a cylindrical mold 9 as a part of the plating tank, and pulse composite Ni-SiC-TiN coating on the inner surface of the cylindrical mold Schematic diagram of the composite coating device for composite coating. The nickel-based composite plating solution 4 is prepared according to the co...

Embodiment 3

[0059] Example 3: Ni-Co-Al composite plating on the inner wall of the square tube mold by voltage control 2 O 3 Nickel alloy base composite coating

[0060] Composite bath composition: Ni(NH 2 SO 3 ) 2 500g / L

[0061] NiCl 2 ·6H 2 O 25g / L

[0062] CoSO 4 50g / L

[0063] H 3 BO 3 55g / L

[0064] Mg 2 SO 4 50g / L

[0065] Lauric acid diacetamide 5g / L

[0066] Al 2 O 3 Nano particles (particle size d=50nm) 30g / L

[0067] Nickel alloy-based composite plating system: Figure 4 shows Ni-Co-Al electroplating on the inner surface of the square tube mold 14 under the condition of mechanical stirring. 2 O 3 Schematic diagram of a nickel alloy-based composite coating device. A stirrer 15 is used to mechanically stir the composite plating solution, the square tube-shaped crystallizer 14 is connected to the negative electrode of the DC power sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com