Scooter made of whisker reinforced C-Al-Cu composite material and its making process

A composite material and whisker technology, which is applied in the formulation and preparation of whisker-reinforced carbon-aluminum-copper composite slides, can solve the problems of cumbersome preparation process of slides, high resistivity of slides, low compressive strength, etc., and achieve high strength, Short production cycle and improved impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

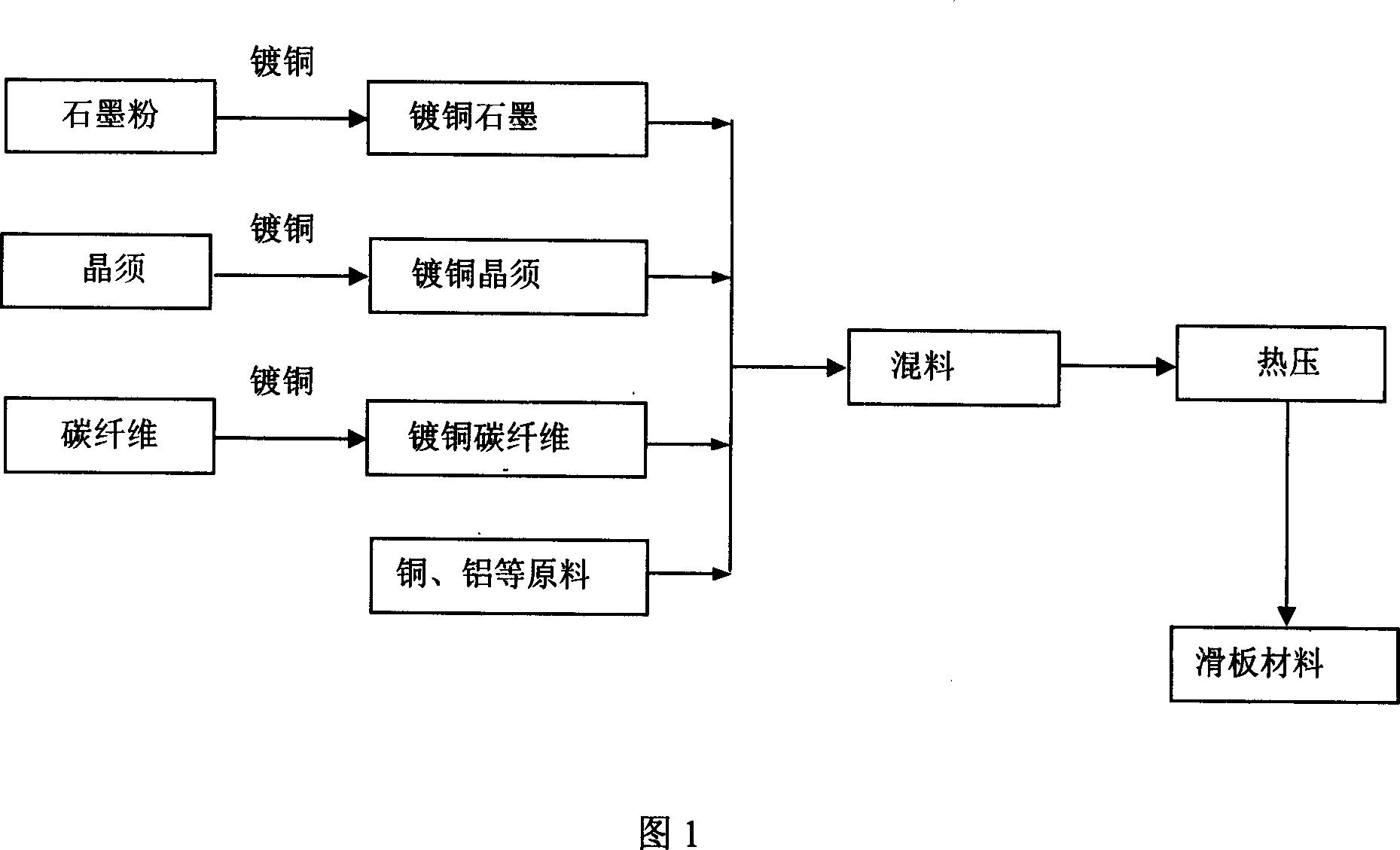

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: copper content 60wt%, whisker content 1.4wt%, graphite content 15wt% in copper-plated graphite powder, carbon fiber content 0.2wt%, aluminum content 15wt%, nickel content 2.4wt%, tin content 5.6wt%, niobium The content is 0.4wt%, and the uniform mixing time in the ball mill tank is 2.5h. After the raw materials are taken out, they are directly hot-pressed. The hot-pressing pressure is 200MPa, the temperature is 860°C, and the density of the skateboard is 4.28g / cm 3 , resistivity 0.18μΩ·m, impact toughness 3.80J / cm 2 , Bending strength 346MPa, friction coefficient 0.075, compressive strength 340MPa.

Embodiment 2

[0022] Embodiment 2: copper content 68wt%, whisker content 2wt%, graphite content 12wt% in copper-plated graphite powder, carbon fiber content 0.2wt%, aluminum content 11wt%, nickel content 1.5wt%, tin content 4.56wt%, niobium content 0.8wt%, the uniform mixing time in the ball mill tank is 3h, after the raw materials are taken out, they are directly hot-pressed, the hot-pressing pressure is 220MPa, the temperature during hot-pressing is 872°C, and the density of the skateboard is 4.4g / cm 3 , resistivity 0.16μΩ m, impact toughness 3.92J / cm 2 , Bending strength 328MPa, friction coefficient 0.062, compressive strength 342MPa.

Embodiment 3

[0023] Embodiment 3: copper content 62wt%, whisker content 3.4wt%, graphite content 12wt% in copper-plated graphite powder, carbon fiber content 0.24wt%, nickel content 3wt%, tin content 2wt%, niobium content 0.36wt%, aluminum content 17wt%, the uniform mixing time in the ball mill tank is 3.8h, after the raw materials are taken out, they are directly hot-pressed, the hot-pressing pressure is 220MPa, the temperature during hot-pressing is 860°C, and the density of the skateboard is 4.31g / cm 3 , resistivity 0.17μΩ·m, impact toughness 3.67J / cm 2 , Bending strength 325MPa, friction coefficient 0.080, compressive strength 322MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com