Method and system for manufacturing semiconductor, base and recording medium used therefor

A device manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, instruments, electrical components, etc., to achieve the effects of simplifying OPC, high precision, and reducing occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

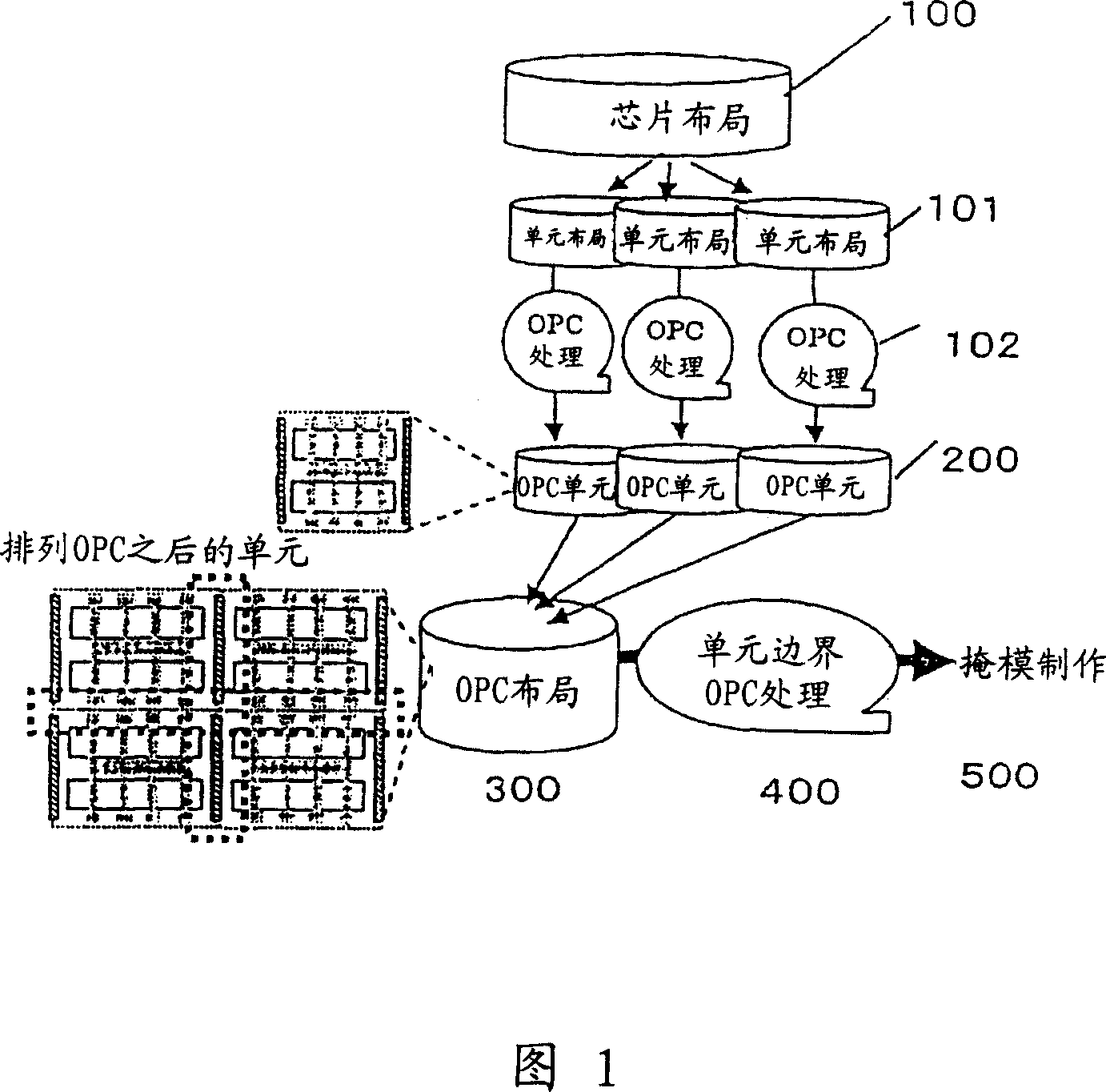

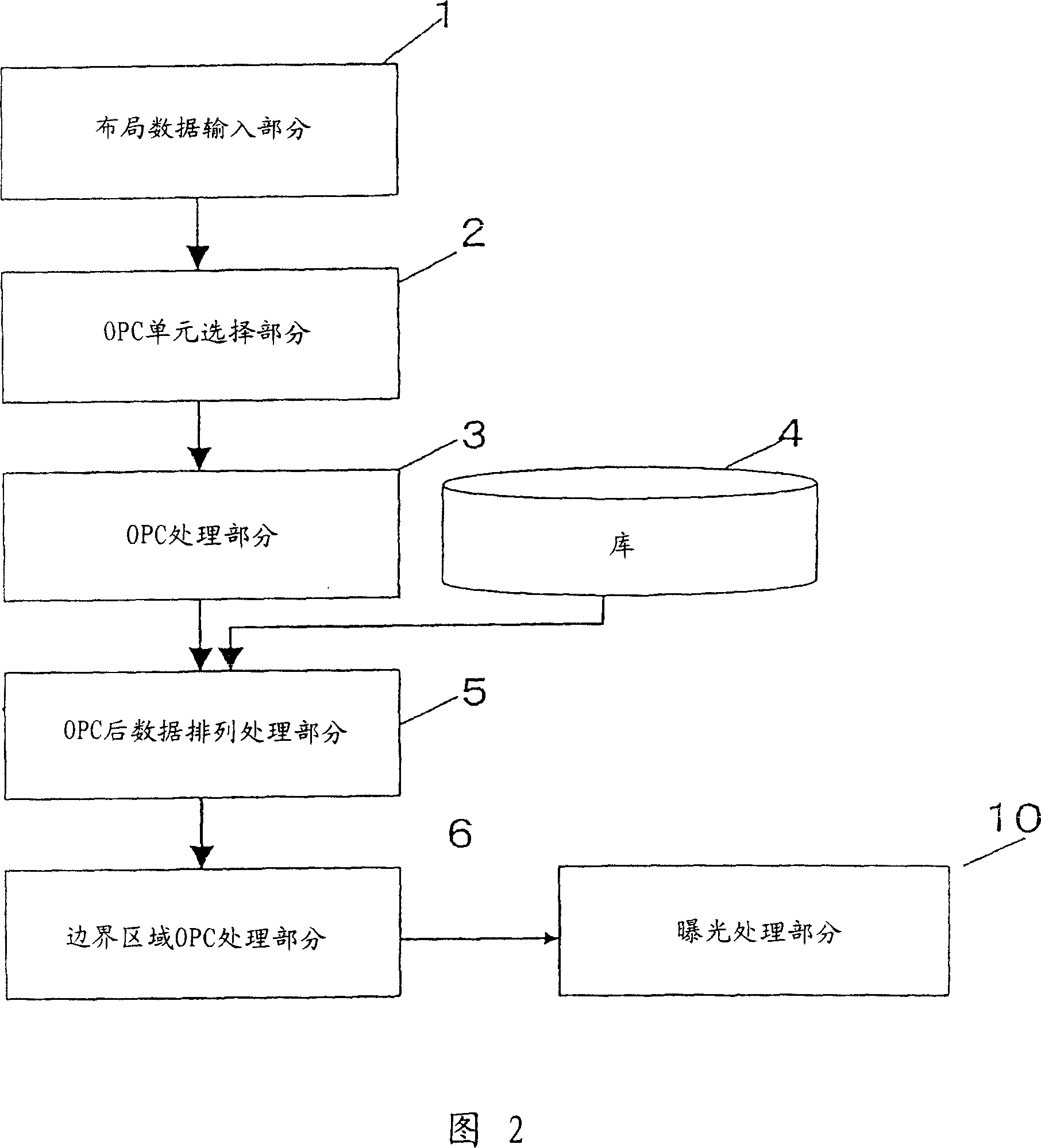

[0059] FIG. 1 is a view showing the concept of the semiconductor device manufacturing method of Embodiment 1 of the present invention.

[0060] As shown in FIG. 1, the method includes the steps of dividing the layout data of the integrated circuit constituting the semiconductor device into a plurality of units; applying the OPC step of optical proximity correction (hereinafter abbreviated as OPC) to each unit; Then, exposure is performed based on the layout data to form a desired pattern; a step of arranging / compositing each OPC-applied cell to which the OPC processing step is applied; and a step of correcting the boundary portion of the cell through the boundary area OPC processing.

[0061] In other words, as shown in the conceptual diagram of FIG. 1, the cell layout data 101 is generated by dividing the layout data 100 for each cell, and then, cell OPC processing is performed on each cell layout data (step 102). Therefore, the OPC unit 200 is obtained. Next, the OPC layout 300 ...

Embodiment 2

[0080] Next, Embodiment 2 of the present invention is explained below.

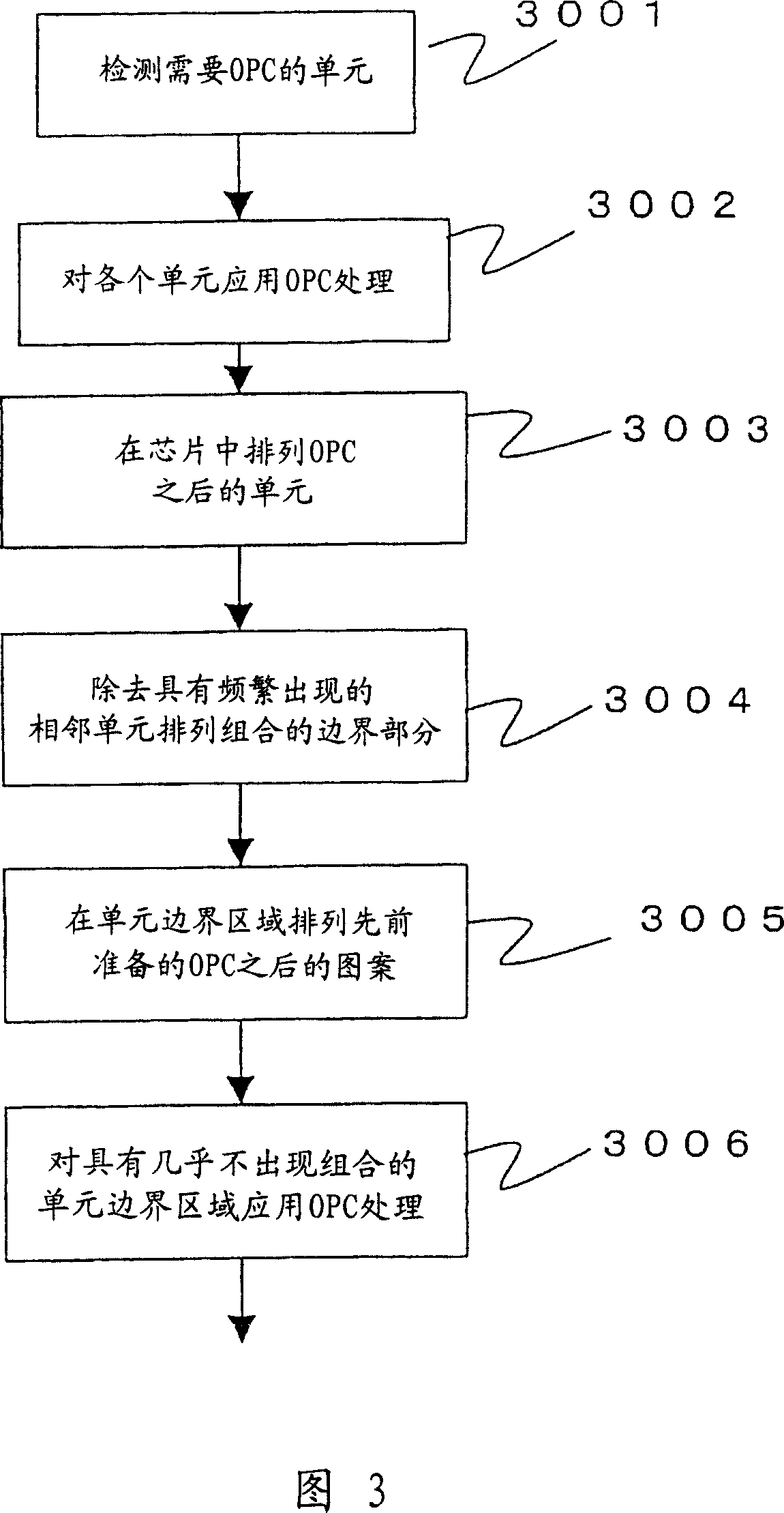

[0081]In the above example 1, select the border parts that frequently appear in the combination of adjacent unit arrangements, then remove the frequently occurring border part patterns, and then take out the border part patterns from the library and arrange them in the corresponding In this area, the correction accuracy can be improved. In this embodiment, simplified correction can be achieved by only reducing the pattern of the adjacent cell boundary area after the arrangement.

[0082] Fig. 5 shows a processing flow for explaining the method.

[0083] First, similar to Embodiment 1, from the layout data input by the layout data input section, a cell requiring OPC is selected at an appropriate level (step 5001). Next, OPC processing is applied to the selected units respectively (step 5002).

[0084] Next, based on the cell layout arrangement information before applying OPC, the cells after the OPC processed ...

Embodiment 3

[0092] Next, Embodiment 3 of the present invention is explained below.

[0093] As shown in FIG. 6, the semiconductor device manufacturing system, in addition to the system shown in FIG. 2 and explained in Embodiment 1, also has a verification function part. The verification function part has: a library / block lithography verification selection part 7 for selecting a cell (block) to be verified from the layout data input by the layout data input part 1; a photolithography verification processing part 8 for The lithography verification is applied to the cell selected by the verification selection section 7; the boundary area photolithography verification processing section 9 is used to apply the lithography verification to the cell boundary area.

[0094] The lithography verification processing section 8 simulates the cells selected by the verification selection section 7 by using the output data of the OPC processing section 3, and then compares the simulation results with the corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com