A Ni-based dual-metal nanocapsule catalyst, and preparation and application thereof

A technology of nanocapsules and catalysts, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, nanotechnology, etc. Interaction and other issues, to reduce the reduction electrode potential, promote rapid formation, and avoid mutual interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

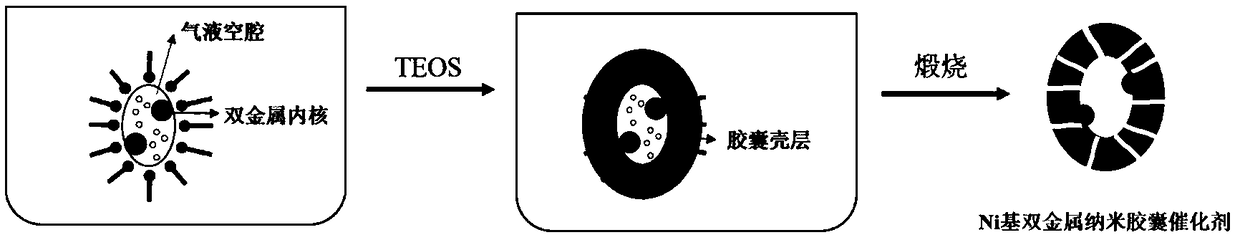

[0035] Example 1: Weigh 10 g of polyoxyethylene (10) cetyl ether into a conical flask, add cyclohexane to 100 mL, heat and stir at 40° C. When it is observed that the solution becomes clear, add 5 mL of 2.0 mol / L nickel nitrate and copper nitrate mixed solution (Ni:Cu molar ratio is 1:1), stir until well mixed, then add 2 mL of hydrazine hydrate. After aging for 0.5h, increase the rotation speed and add a mixed solution of 2ml of concentrated ammonia water (25wt.%) and 13mL of deionized water, then slowly add 10mL of TEOS, after hydrolysis for 1h, add isopropanol to break the emulsion, and centrifuge. Finally, the obtained sample was dried at 110° C. for 12 h, and then calcined at 500° C. at a rate of 1° C. / min in an air atmosphere to obtain bimetallic nanocapsule catalyst 1 .

[0036] The calcined catalyst 1 was pressed into tablets and sieved, and 0.1g of the 20-40 mesh catalyst was taken, mixed evenly with quartz sand and then put into a reaction tube, and then reduced for ...

Embodiment 2

[0037] Example 2: Weigh 20 g of polyoxyethylene (10) cetyl ether into a conical flask, add cyclohexane to 100 mL, heat and stir at 45° C. When it is observed that the solution becomes clear, add 7 mL of 1.8 mol / L nickel nitrate and cobalt nitrate mixed solution (Ni:Co molar ratio is 2:1), stir until well mixed, then add 3 mL of hydrazine hydrate. After aging for 1.5 hours, increase the speed and add a mixed solution of 1.5ml of concentrated ammonia water and 13.5mL of deionized water, then slowly add 12.5mL of TEOS, after hydrolysis for 6 hours, add isopropanol to break the emulsion, and centrifuge. Finally, the obtained sample was dried at 80° C. for 24 h, and then calcined at 600° C. at a rate of 1.5° C. / min in an air atmosphere to obtain bimetallic nanocapsule catalyst 2 .

[0038] The calcined catalyst 2 was pressed into tablets and sieved, and 0.1g of 40-60-mesh catalyst was taken, mixed evenly with quartz sand, and then put into a reaction tube, and then reduced for 1 ho...

Embodiment 3

[0039] Example 3: Weigh 34g of polyoxyethylene (10) cetyl ether into a conical flask, add cyclohexane to 100mL, heat and stir at 50°C. When it is observed that the solution becomes clear, add 5 mL of 1.5 mol / L nickel nitrate and copper nitrate mixed solution (Ni:Cu molar ratio is 4:1), stir until well mixed, then add 4 mL of hydrazine hydrate. After aging for 3 hours, increase the rotation speed and add a mixed solution of 1ml of concentrated ammonia water and 14mL of deionized water, then slowly add 10mL of TEOS, after hydrolysis for 12h, add isopropanol to break the emulsion, and centrifuge. Finally, the obtained sample was dried at 100° C. for 12 h, and then calcined at 700° C. at a rate of 2° C. / min in an air atmosphere to obtain bimetallic nanocapsule catalyst 3 .

[0040] The calcined catalyst 3 was pressed into tablets and sieved, and 0.1g of 20-40 mesh catalyst was taken, mixed evenly with quartz sand and then put into a reaction tube, and then reduced for 1 hour at 70...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com