Manufacturing method of catalyst for pentafluoroethane

A technology of pentafluoroethane and catalyst, which is applied in the field of preparing the catalyst, and can solve the problem of low selectivity of HFC-125

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

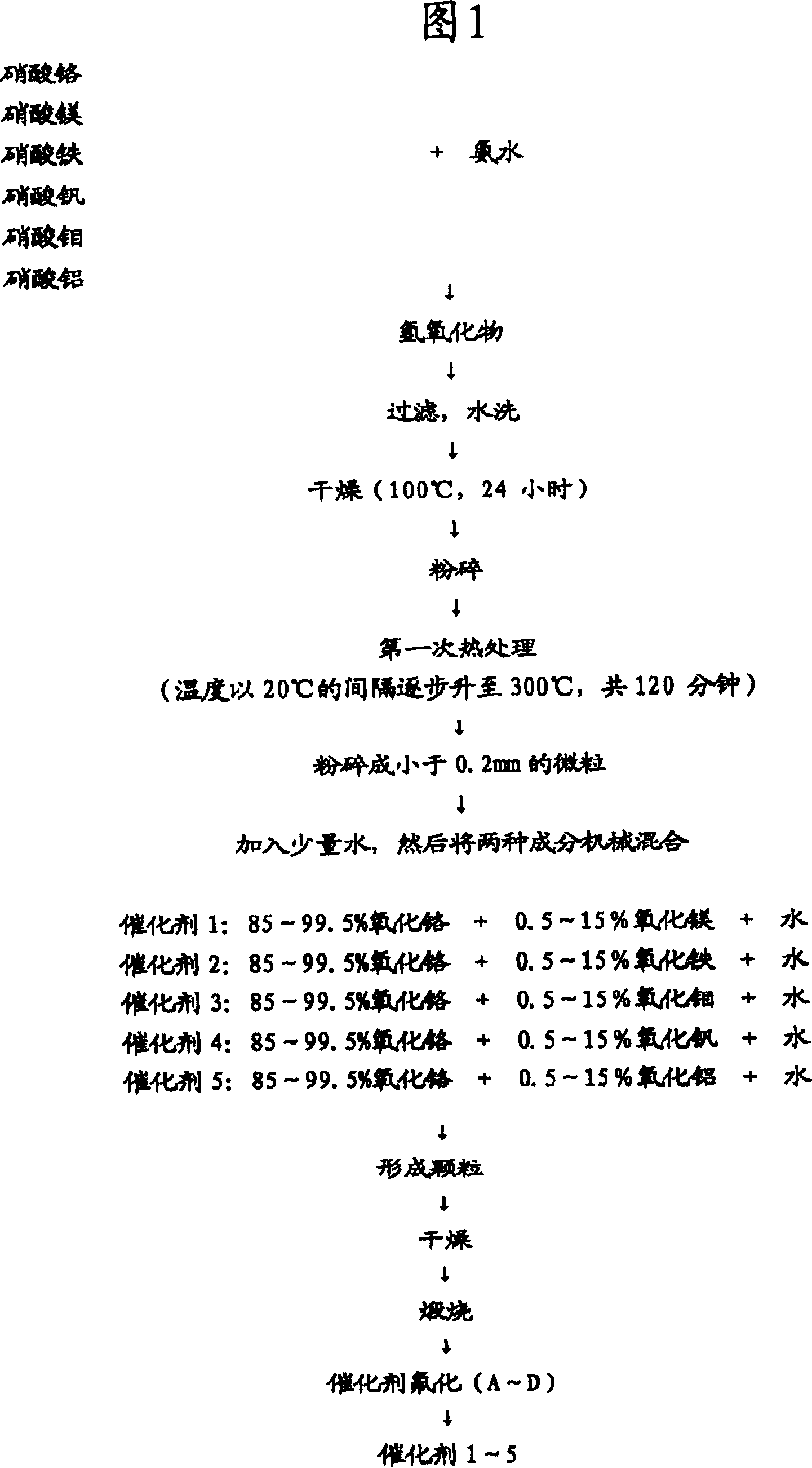

[0034] Fluorinated catalysts 1-5 were prepared according to the method shown in the steps of FIG. 1 . In Figure 1, catalyst 1 is composed of chromium oxide and magnesium oxide, catalyst 2 is composed of chromium oxide and iron oxide, catalyst 3 is composed of chromium oxide and molybdenum oxide, catalyst 4 is composed of chromium oxide and vanadium oxide, and catalyst 5 is composed of chromium oxide composed of alumina. Next, a catalyst composed of chromium oxide and magnesium oxide will be described.

[0035] In 1kg chromium(III) nitrate (Cr(NO 3 ) 3 9H2O) was dissolved in distilled water, and 0.391kg of ammonia (NH2O) was added dropwise 4 OH), so that blue-gray chromium hydroxide (Cr(OH) 3 )precipitation. The precipitate was washed well with hot distilled water, filtered and dried at 100°C for 24 hours to obtain solid chromium hydroxide. The chromium hydroxide thus obtained is ground into powder with a ball mill or a mortar, and then heat-treated. Heat treatment was p...

Embodiment 2

[0038] (Preparation of catalyst 2 (chromium oxide-iron oxide catalyst))

[0039] Catalyst 2 is prepared in the same manner as in Example 1, except that iron nitrate [Fe(NO 3 ) 2 ·6H 2 O] instead of magnesium nitrate.

Embodiment 3

[0041] (Preparation of catalyst 3 (chromium oxide-molybdenum oxide catalyst))

[0042] Catalyst 3 is prepared in the same manner as in Example 1, except that ammonium molybdate [(NH 4 ) 6 Mo 7 o 24 ] instead of magnesium nitrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com