Organic group functionized mesoporous molecular sieve enzyme immobilized carrier, and its preparing method

A technology of immobilized carrier and mesoporous molecular sieve, which is applied in the direction of immobilization on or in the inorganic carrier, can solve the problem of late start of research on immobilized carrier materials, and achieve the effect of mild immobilization reaction conditions and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of epoxidized mesoporous carrier by grafting method.

[0033] The mass ratio of the raw materials is: toluene: polyoxyethylene ether-polyoxypropylene ether-polyoxyethylene ether: ethyl orthosilicate: hydrochloric acid=1:1:1.5:35. Among them, toluene is a pore expander. The operation is as follows: Dissolve polyoxyethylene ether-polyoxypropylene ether-polyoxyethylene ether in an HCl solution at about 30°C. The concentration of the HCl solution is 1.0 mol / L. Under stirring, slowly add toluene and ethyl orthosilicate in sequence After the obtained sol was continuously stirred for 24 hours, it was transferred to a crystallization kettle and allowed to stand for crystallization at 110°C for 24 hours. The obtained colloid is filtered, washed, dried at 90 DEG C, and calcined at 500 DEG C for at least 15 hours to obtain the original powder of mesoporous molecular sieve. The raw powder of mesoporous molecular sieve is vacuum degassed and put into a three-necked flask, an...

Embodiment 2

[0037] Preparation of epoxidized mesoporous carrier by grafting method.

[0038] The mass ratio of the raw materials is: trimethylbenzene: polyoxyethylene ether-polyoxypropylene ether-polyoxyethylene ether: ethyl orthosilicate: hydrochloric acid = 0.1:1:4.5:70. Among them, trimethylbenzene is a hole expander. The operation is as follows: Dissolve polyoxyethylene ether-polyoxypropylene ether-polyoxyethylene ether in a 1.8mol / L HCl solution at 40°C, slowly add ethyl orthosilicate with stirring, and the resulting sol will continue to be stirred for 48 hours, then turn Put it into the crystallization kettle and let it stand for crystallization at 120°C for 30h. The obtained colloid is filtered, washed, dried at 120°C, and calcined at 650°C for at least 8 hours to obtain the original powder of mesoporous molecular sieve. The raw powder of mesoporous molecular sieve is vacuum degassed and put into a three-necked flask, and 20% of its mass is added with 3-oxyglycidyl-propyl-trimethoxysil...

Embodiment 3

[0041] Preparation of aminated mesoporous carrier by grafting method.

[0042] The mass ratio of the reagents is: trimethylbenzene: polyoxyethylene ether-polyoxypropylene ether-polyoxyethylene ether: ethyl orthosilicate: hydrochloric acid = 0.2:1:2.5:45. Among them, trimethylbenzene is a hole expander. The operation is as follows: Dissolve polyoxyethylene ether-polyoxypropylene ether-polyoxyethylene ether in a 1.8mol / L HCl solution at 35℃, add trimethylbenzene and ethyl orthosilicate with stirring, and the resulting sol is continuously stirred for 24 hours. , Transferred to the crystallization kettle and allowed to stand for crystallization at 100°C for 24h. The obtained colloid is filtered, washed, and finally extracted with ethanol in a Soxhlet extractor to remove polyoxyethylene ether-polyoxypropylene ether-polyoxyethylene ether to obtain mesoporous molecular sieve raw powder. The raw powder of mesoporous molecular sieve is dispersed in toluene, and the mass ratio of γ-aminopro...

PUM

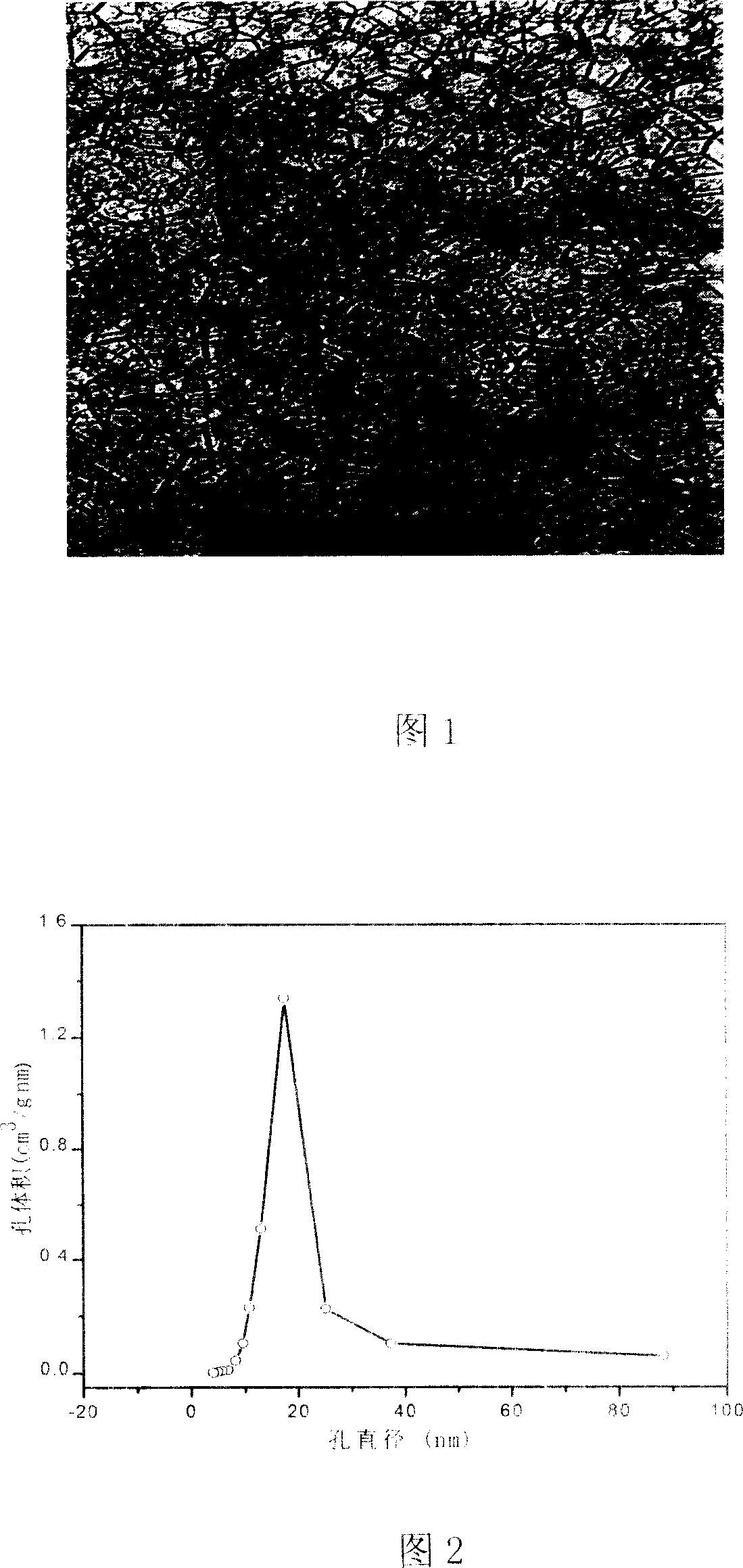

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com