Application of a Functionalized Ionic Liquid Modified Mesoporous Molecular Sieve in Enzyme Immobilization

A technology of mesoporous molecular sieve and ionic liquid, which is applied in the direction of immobilization on/in the organic carrier, can solve the problems of mass transfer limitation, large amount of ionic liquid, high viscosity, etc., and achieve mild immobilization reaction conditions, activity and stability The effect of high reliability and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

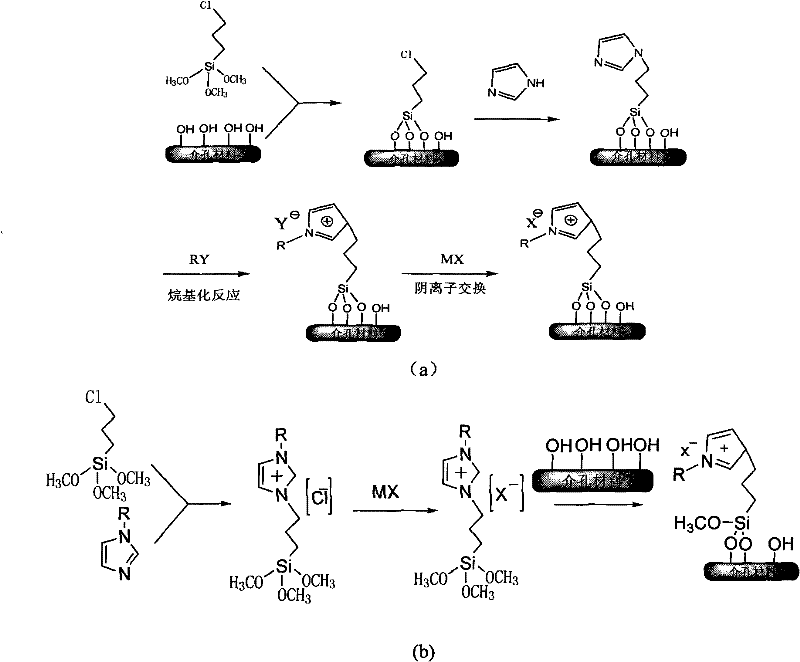

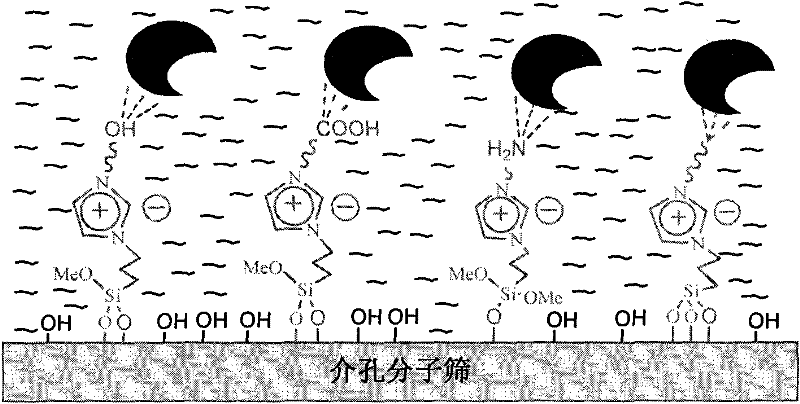

Method used

Image

Examples

Embodiment 1

[0037] 1) Synthesis of mesoporous molecular sieve SBA-15: According to the description of Zhao Dongyuan et al. (Triblock Copolymer Syntheses of Mesoporous Silica with Periodic 50 to 300 Angstrom Pores. Science, 1998, 279: 548-553), the original powder of SBA-15 molecular sieve was prepared , with a pore size of 10nm and a specific surface area of 350m 2 / g.

[0038] 2) Synthesis of functionalized ionic liquid: 1-methylimidazole and chloropropyltrimethoxysilane were refluxed at 120°C for 40 hours, cooled to room temperature, and the obtained product was stirred with KPF6 in acetone at room temperature for three days to obtain Functionalized ionic liquid crude liquid, the ionic liquid crude liquid is filtered, washed, separated, and acetone and water are distilled off under reduced pressure to obtain a functionalized ionic liquid, wherein 1-methylimidazole, chloropropyltrimethoxysilane and KPF 6 The molar ratio is 1:1:1.

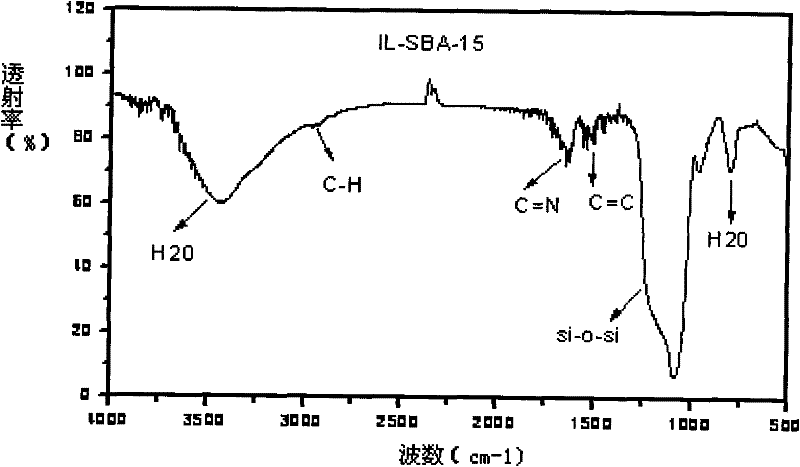

[0039] 3) Preparation of functionalized ionic liqui...

Embodiment 2

[0053] 1) Synthesis of mesoporous molecular sieve MCM-48: According to the description of Mobil Company in (Ordered mesoporous molecular sievessynthesized by a liquid-crystal template mechanism. Nature, 1992.359 (6397): 710-712), the original MCM-41 molecular sieve was prepared powder, the pore size is 5nm, and the specific surface area is 1500m 2 / g.

[0054] 2) Synthesis of functionalized ionic liquid: 1-butylimidazole and chloropropyltrimethoxysilane were refluxed at 120°C for 40 hours (with a drying tube), cooled to room temperature to obtain the product. The obtained product was mixed with KPF 6 Stir in acetone at room temperature for three days to obtain an ionic liquid. The obtained product is filtered, washed, separated, and acetone and water are distilled off under reduced pressure to obtain an ionic liquid, in which 1-butylimidazole, chloropropyltrimethoxysilane and KPF 6 The molar ratio is 1:1:1.

[0055] 3) Preparation of functionalized ionic liquid modified meso...

Embodiment 3

[0058] 5) 1) Synthesis of mesoporous molecular sieve MCM-48: According to the description of Mobil Corporation in (Ordered mesoporous molecular sievessynthesized by a liquid-crystal template mechanism. Nature, 1992.359(6397): 710-712), MCM-48 was prepared Molecular sieve raw powder, the pore size is 8nm, the specific surface area is 1400m 2 / g.

[0059] 2) Synthesis of functionalized ionic liquid: 1-ethylimidazole and chloropropyltrimethoxysilane were reacted under reflux at 120°C for 40 hours (with a drying tube), cooled to room temperature to obtain the product. Combine the obtained product with KPF 6 Stir in acetone at room temperature for three days to obtain an ionic liquid. The obtained product is filtered, washed, separated, and acetone and water are distilled off under reduced pressure to obtain an ionic liquid. Among them, 1-ethylimidazole, chloropropyltrimethoxysilane and KPF 6 The molar ratio is 1:1:1.

[0060] 3) Preparation of functionalized ionic liquid modifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com