Rubber made canister and manufacture method of the same

A manufacturing method and rubber technology, which is applied to gas shock absorbers, elastic couplings, mechanical equipment, etc., can solve the problems of diameter expansion obstruction, time-consuming and labor-intensive configuration, and increased ply cut-off loss, etc., to achieve compact thickness, Improved durability and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

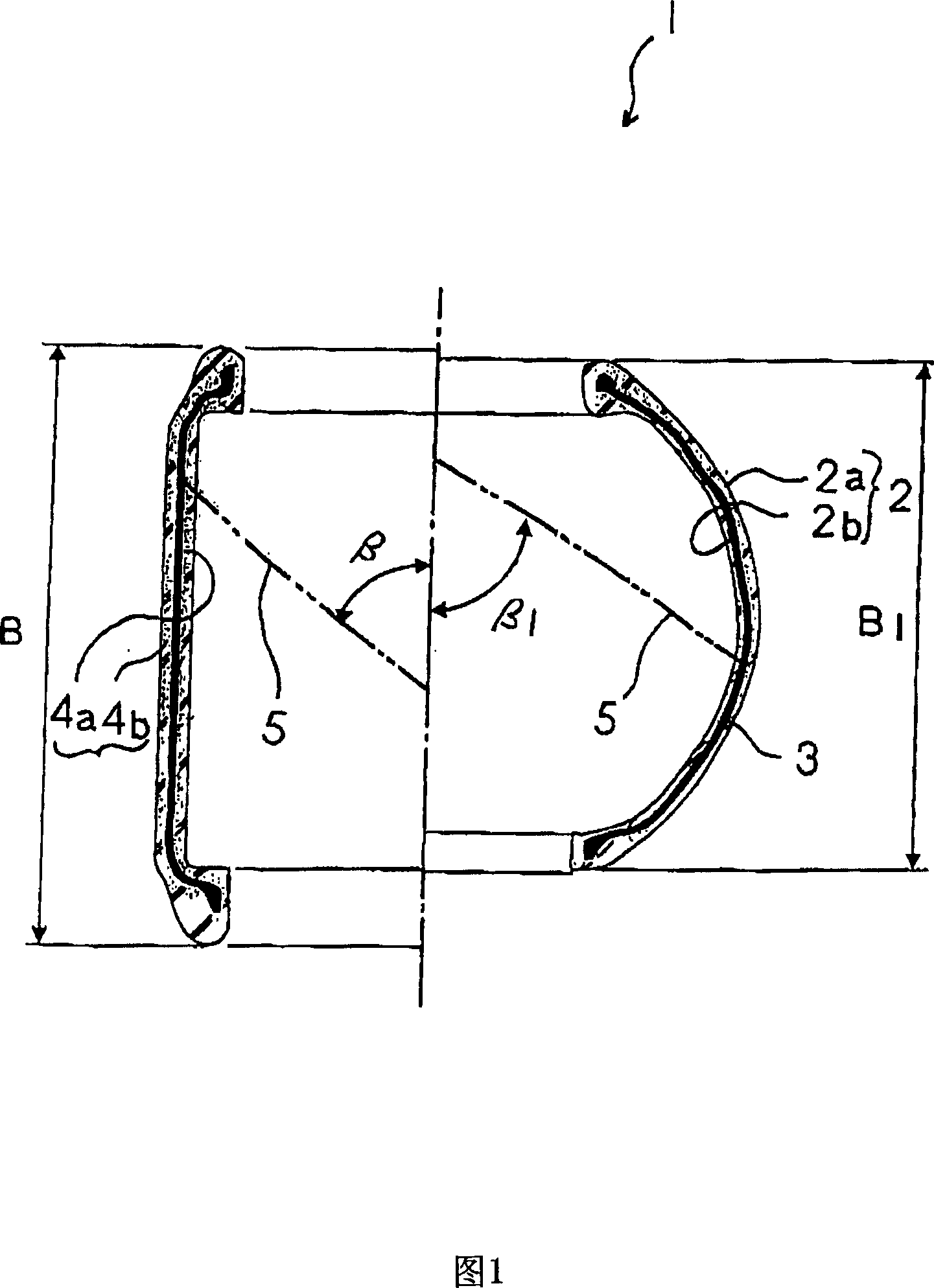

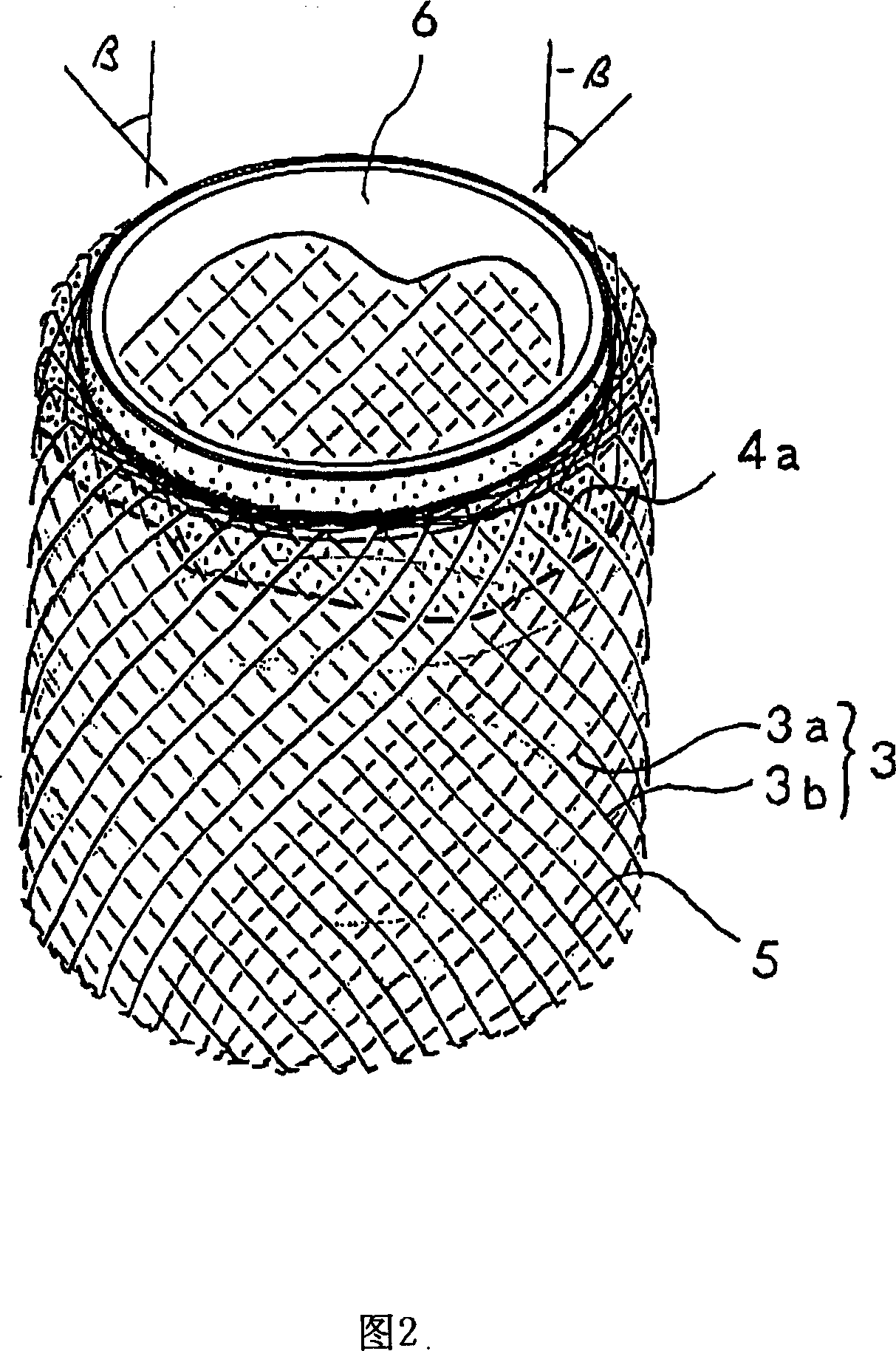

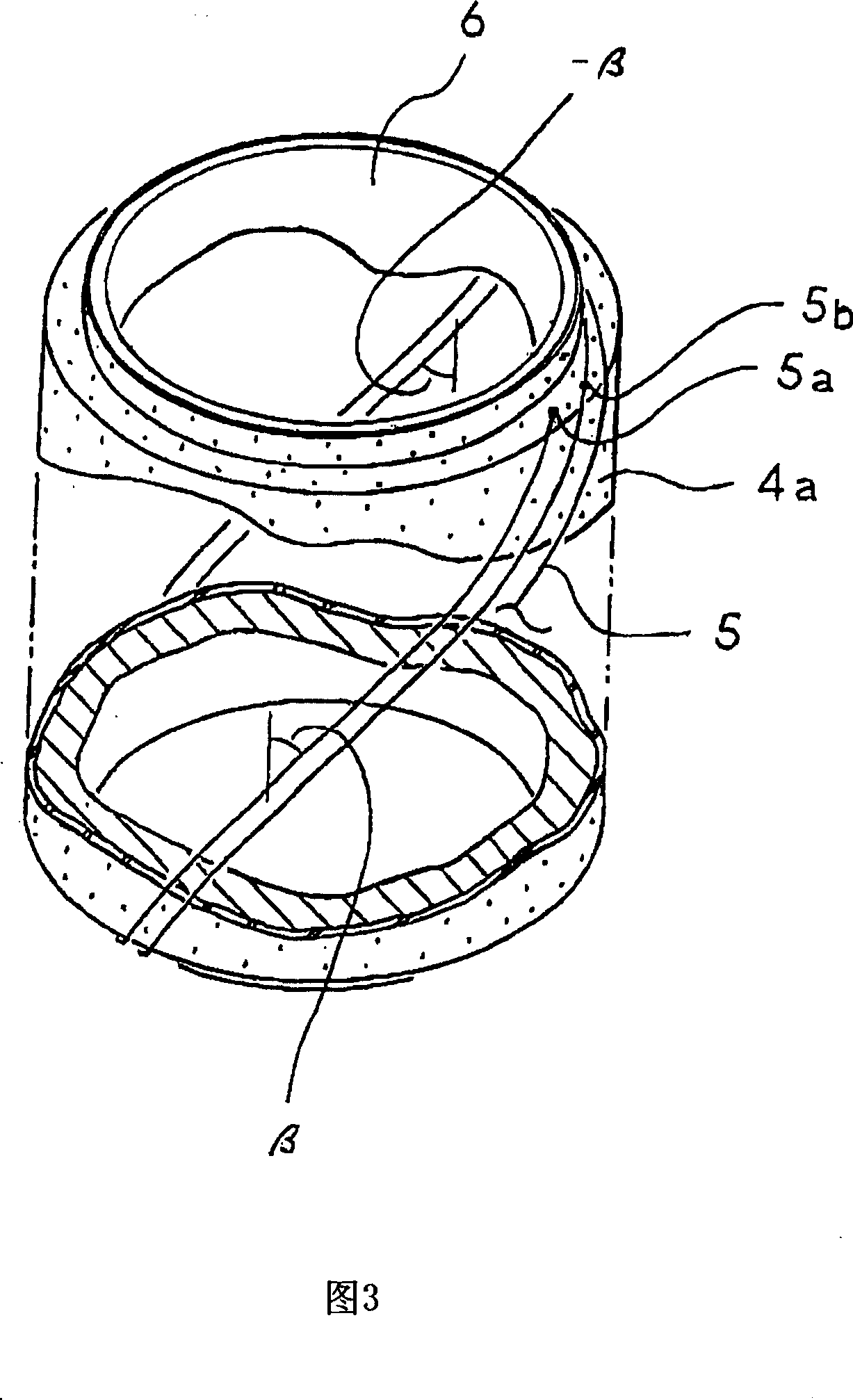

[0079]1 is a cross-sectional view of a rubber cylinder according to a first embodiment of the present invention. The left half shows the state before vulcanization molding, and the right half shows the state after vulcanization molding. Fig. 2 is a perspective view showing a reinforcing ply, showing a state formed on the outside of the unvulcanized rubber on the inner surface of the mold and the forming mold. In addition, in FIG. 2, only the upper part of the molding die and the unvulcanized rubber on the inner surface are illustrated.

[0080] The rubber cylinder 1 of the first embodiment is, for example, a member for fixing fittings at both ends to serve as a diaphragm of an air spring, and has a structure in which the diameter at the center is larger than the diameter at both ends and as a whole The cylindrical rubber membrane 2 having a substantially spherical shape is provided with a reinforcing ply 3 for increasing resistance to internal pressure and transmission force.

[0...

no. 2 approach

[0110] 10 is a cross-sectional view of a rubber cylinder according to a second embodiment of the present invention. The left half shows the state before vulcanization molding, and the right half shows the state after vulcanization molding. Fig. 11 is a side view of the linear member, and the left end shows an axial cross-sectional view. Fig. 12 is a transverse cross-sectional view of the linear member. Fig. 13 is a schematic diagram showing the connection of both ends of the linear member, (a) shows the state before connection, and (b) shows the state after connection.

[0111] The rubber cylinder 11 of the second embodiment is used, for example, as a diaphragm of a piston-type air spring mounted on a truck or a bus. The upper end is sandwiched by a pair of connecting fittings 12a, 12b, and the lower end is press-fitted. The insertion portion 13a of the piston 13. Although the structure of this rubber-made cylinder 11 is substantially the same as the rubber-made cylinder 1 of 1st ...

no. 3 approach

[0150] 21 is a cross-sectional view of a rubber cylinder according to a third embodiment of the present invention. The left half shows the state before vulcanization molding, and the right half shows the state after vulcanization molding. Fig. 22 is a perspective view showing the reinforcing ply, and the illustration of the rubber film thereof is omitted.

[0151] The rubber cylinder 25 of the third embodiment is, for example, a member used as a diaphragm of an air spring, and has almost the same structure as the rubber cylinder 1 of the first embodiment, but a pair of fittings 26 are integrally fixed at both ends , 27, and constitute a rubber cylinder 28 with fittings.

[0152] As in the first embodiment, the reinforcing cord layer 3 is composed of a single reinforcing cord 5 surrounding the central axis of the rubber tube 25. The one reinforcing cord 5 is wrapped around the fittings 26, 27, and the hooking portion 5c of the reinforcing cord 5 is hooked on the peripheral edge of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com