Method of fabricating a semiconductor device

A technology of semiconductors and devices, applied in the field of manufacturing semiconductor devices, can solve problems such as increasing off-current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

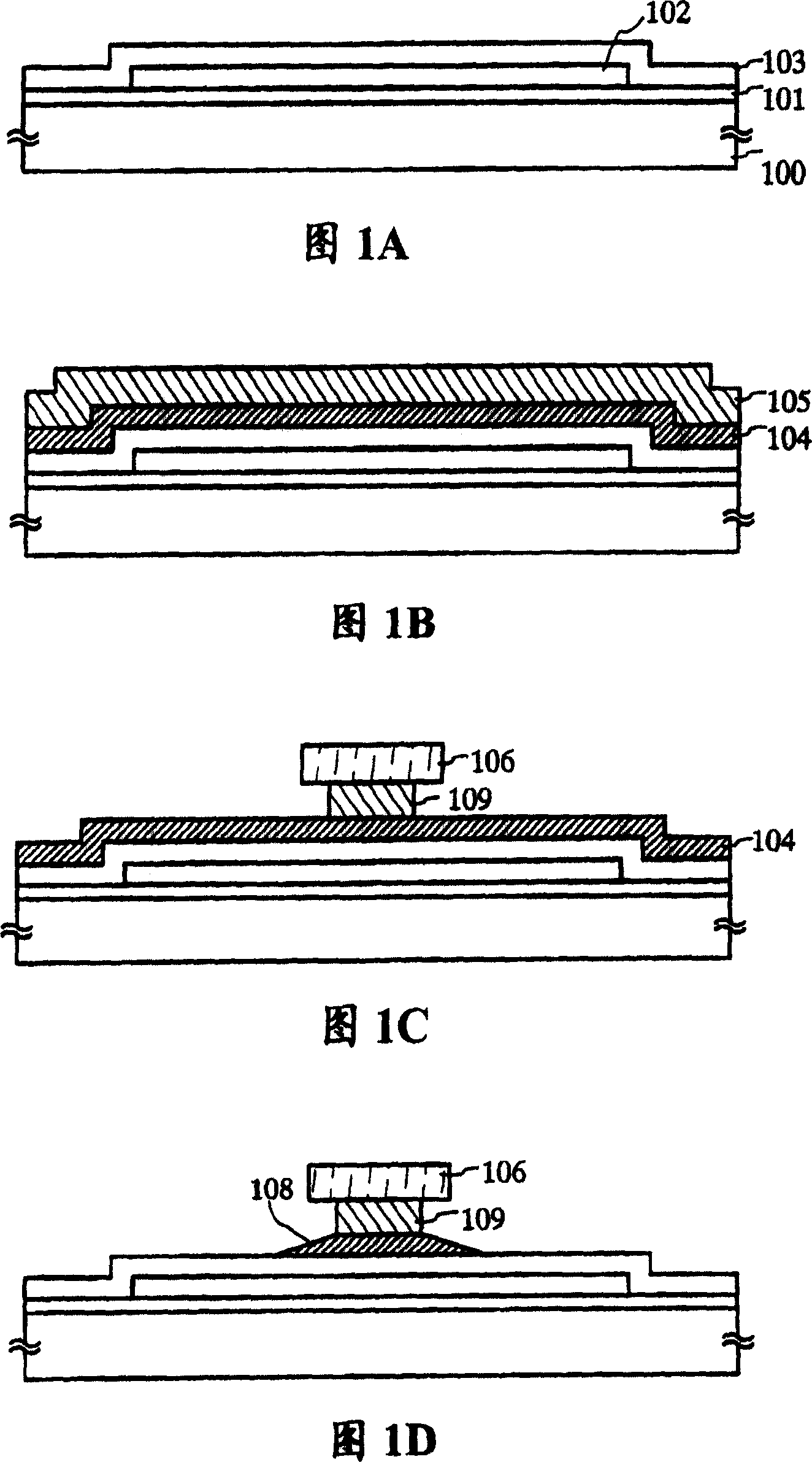

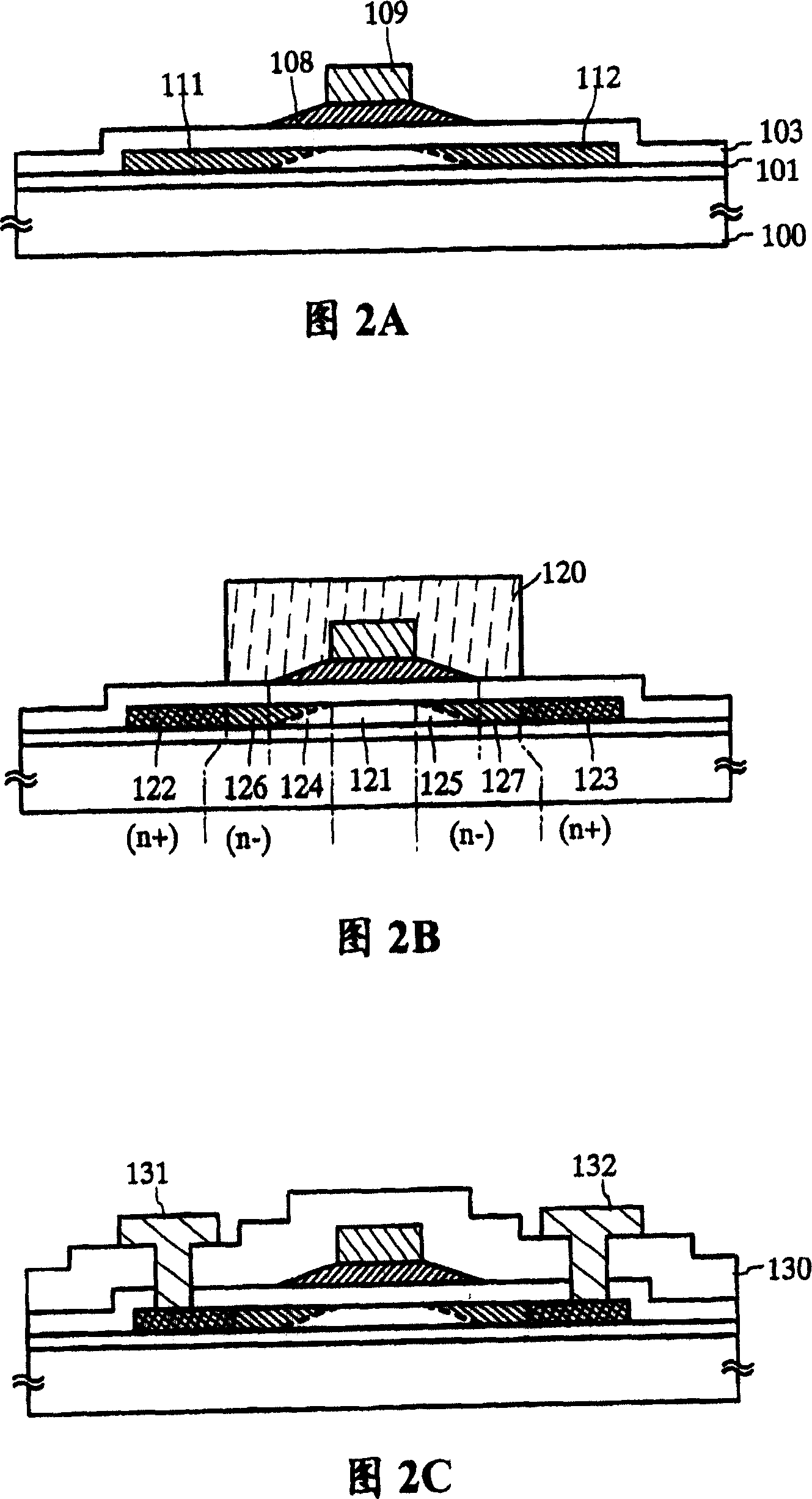

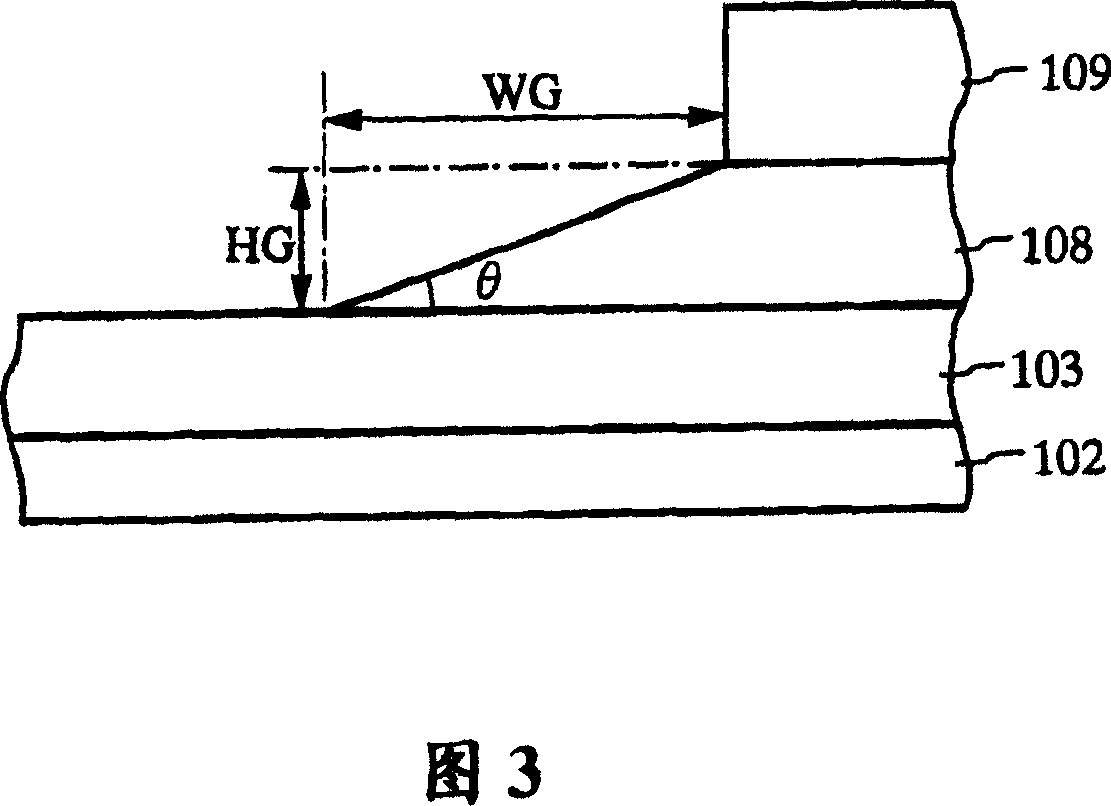

Method used

Image

Examples

Embodiment 1

[0166] Embodiment 1 is an embodiment in which the present invention is applied to an active matrix liquid crystal display device.

[0167] Fig. 10 is a schematic configuration diagram of the active matrix type liquid crystal display panel of this embodiment. The structure of the liquid crystal panel is that the liquid crystal is held between the active matrix substrate and the counter substrate, and a voltage corresponding to image data is applied to the liquid crystal through electrodes formed on the active matrix substrate and the counter substrate to form a liquid crystal on the panel. Display the image.

[0168] On the active matrix substrate 200 , a pixel portion 202 using TFTs as switching elements, and a gate driver circuit 203 and a source driver circuit 204 for driving the pixel portion 202 are formed on a glass substrate 300 . The driving circuits 203 and 204 are connected to the pixel portion 202 via source wiring and drain wiring, respectively.

[0169] Also, a s...

Embodiment 2

[0203] This embodiment is an improved example of embodiment 1, but the order of adding steps of phosphorus and boron is changed, and the others are the same as embodiment 1. The manufacturing steps of this embodiment will be described with reference to FIGS. 17A-17E. In FIGS. 17A-17E, the same reference numerals as those in FIGS. 15A-15F and 16A-16E denote the same structural elements.

[0204] Although in Example 1 boron was added after phosphorus was added to the semiconductor layer, in Example 2 boron was added first.

[0205] Although the manufacturing steps of a CMOS circuit are described in this embodiment, it goes without saying that this embodiment is applicable to the manufacturing steps of an active matrix substrate in Embodiment 1 on which a pixel portion and a driver circuit are integrated.

[0206] The structure of Fig. 15E is realized according to the steps shown in Embodiment 1. Next, the resist mask 405 is removed. Fig. 17A shows this state.

[0207] After ...

Embodiment 3

[0218] Also in this embodiment, similar to Embodiment 2, a manufacturing step in which the order of phosphorus and boron addition steps is changed is described. The manufacturing steps of this embodiment are described with reference to Figs. 18A-18E. In Figs. 18A-18E, the same reference numerals as in Figs. 15A-15F and 16A-16E denote the same structural elements.

[0219] Likewise, this embodiment corresponds to an improved example of Embodiment 2. In Example 2, boron was added after phosphorus was added at a low concentration in manufacturing an n-channel TFT. However, this example is an example in which boron is first added at a high concentration.

[0220] The structure of Fig. 15E is realized according to the steps shown in Embodiment 1. Next, the resist mask 405 is removed. Fig. 18A shows this state.

[0221] After that, a resist mask 600 covering the n-channel TFT is formed. Boron is added to the semiconductor layer 304 by an ion doping method using the resist mask...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com