Vertical color filter sensor group and semiconductor integrated circuit fabrication method for fabricating same

A sensor group, sensor technology, applied in the direction of semiconductor devices, circuits, electrical components, etc., can solve the problems of non-standard manufacturing technology, inability to choose different color readout, and high sensor density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Those of ordinary skill in the art will appreciate that the following description of the invention is illustrative only and not restrictive in any way. Other embodiments of the invention will readily occur to those skilled in the art having the benefit of the invention.

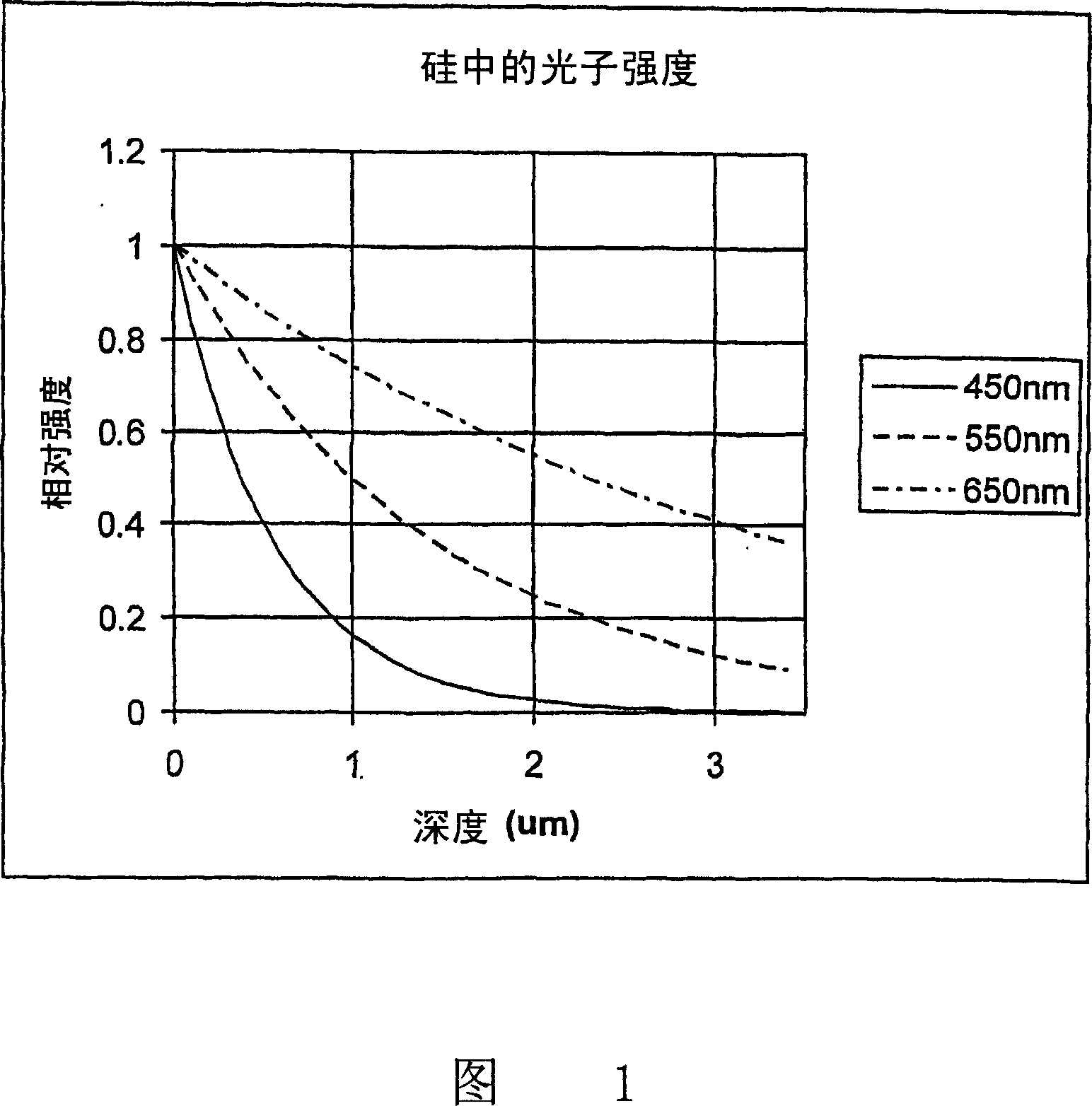

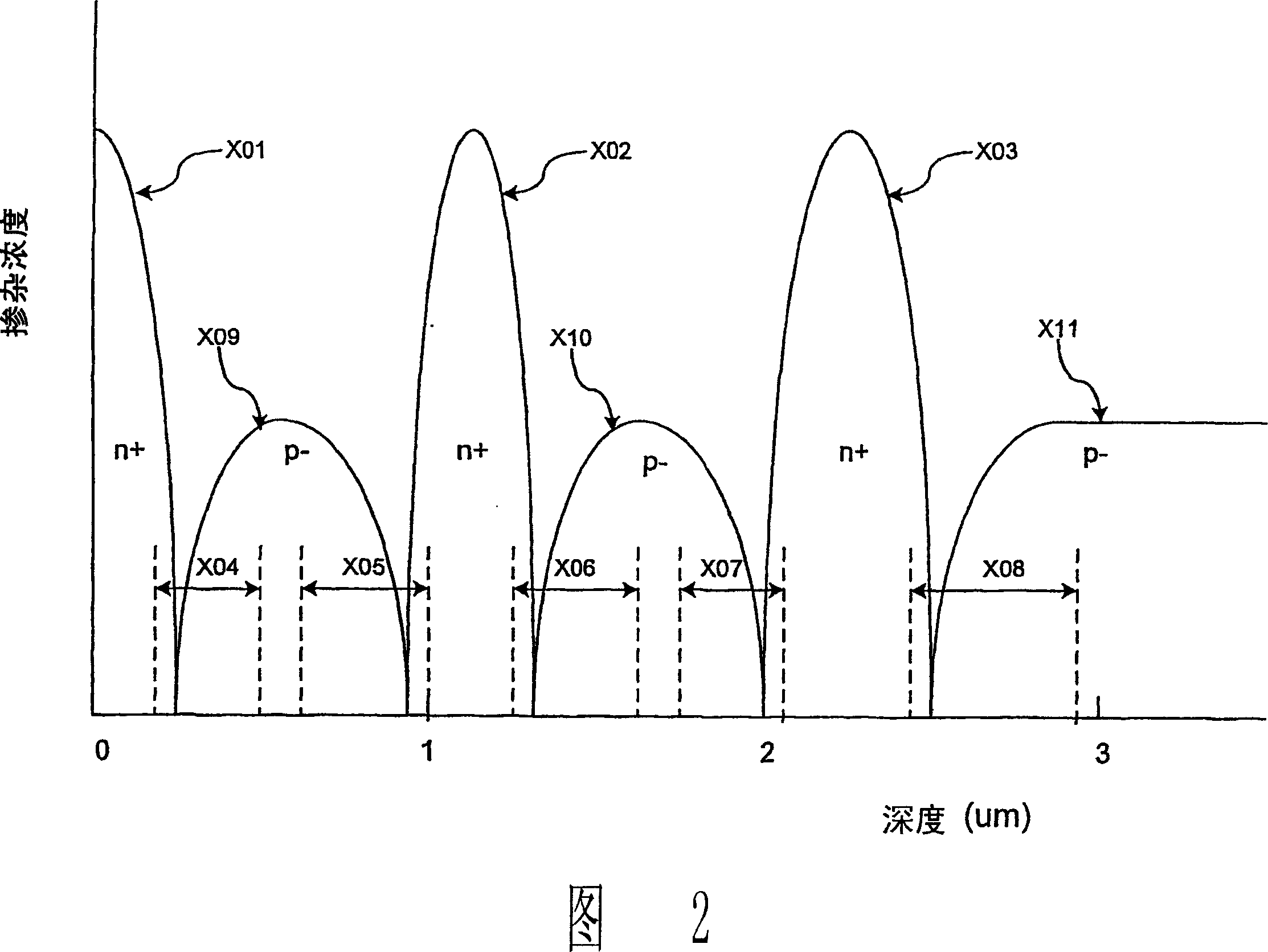

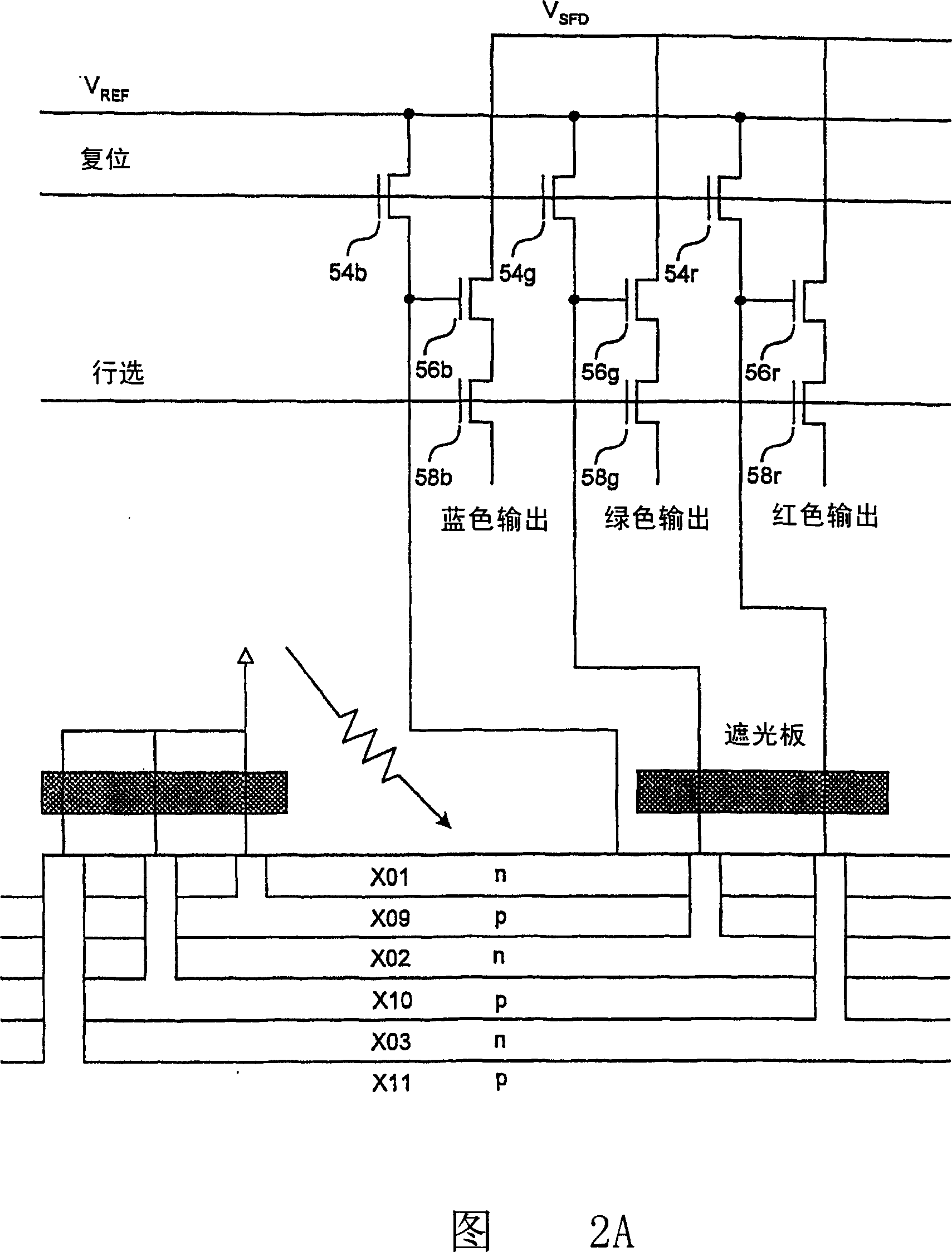

[0058] Most of the fabrication process to be described herein assumes that the sensor is made of crystalline silicon, but the method (or modifications to it that will be obvious to those skilled in the art) can generally be applied to sensors made of other semiconductor materials as well. . Each sensor of the VCF sensor group detects photons by directly or indirectly converting the energy of the photons into electron-hole pairs. This occurs in semiconducting materials. Groups of VCF sensors are typically implemented such that the output of each sensor in the group represents a different waveband of incident radiation. The radiation reaching each sensor in the VCF sensor group has a different wavelengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com